ATM121-Automotive-Electronics.docx

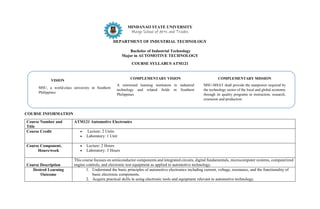

- 1. MINDANAO STATE UNIVERSITY Maigo School of Arts and Trades DEPARTMENT OF INDUSTRIAL TECHNOLOGY Bachelor of Industrial Technology Major in AUTOMOTIVE TECHNOLOGY COURSE SYLLABUS ATM121 COURSE INFORMATION Course Number and Title ATM121 Automotive Electronics Course Credit Lecture: 2 Units Laboratory: 1 Unit Course Component, Hours/week Lecture: 2 Hours Laboratory: 3 Hours Course Description This course focuses on semiconductor components and integrated circuits, digital fundamentals, microcomputer systems, computerized engine controls, and electronic test equipment as applied to automotive technology. Desired Learning Outcome 1. Understand the basic principles of automotive electronics including current, voltage, resistance, and the functionality of basic electronic components. 2. Acquire practical skills in using electronic tools and equipment relevant to automotive technology. VISION MSU, a world-class university in Southern Philippines COMPLEMENTARY VISION A renowned learning institution in industrial technology and related fields in Southern Philippines COMPLEMENTARY MISSION MSU-MSAT shall provide the manpower required by the technology sector of the local and global economy through its quality programs in instruction, research, extension and production

- 2. 3. Gain knowledge of the design and operation of automotive electronic systems like the ignition system and ECM. Prerequisite Automotive Electrical System Co-requisite None Reference/s 1. Textbooks: o "Automotive Electronics Handbook" by Ronald K. Jurgen. This book offers a detailed overview of automotive electronics, covering everything from basic concepts to more advanced applications. o "Understanding Automotive Electronics: An Engineering Perspective" by William B. Ribbens. This text provides an engineering-focused approach to automotive electronics, explaining the principles behind the technology. o "Advanced Automotive Electricity and Electronics" by Michael Klyde. This is an excellent resource for understanding modern automotive electrical systems, including computerized engine controls. 2. Online Resources: o SAE International Journals and Publications: SAE International provides numerous journals and papers on the latest advancements in automotive electronics. [Website: sae.org] o IEEE Xplore Digital Library: For research papers and articles on automotive microcomputer systems and semiconductor components. [Website: ieeexplore.ieee.org] 3. Laboratory Manuals: o Laboratory manuals specifically designed for automotive electronics labs, often provided by equipment manufacturers or educational institutions. 4. Professional Websites and Forums: o Websites such as Automotive Electronics Services, Inc. (AESwave.com) and ECM (Engine Control Module) specific forums for practical insights and troubleshooting. 5. Industry Magazines: o Magazines like "Automotive Engineer" and "Car Electronics" for updates on the latest trends and technologies in automotive electronics. 6. Supplier Catalogs: o Catalogs from automotive electronics suppliers, like Bosch, for detailed specifications and applications of various components. Other Supplemental Materials 1. Videos and Tutorials: o Online video tutorials on platforms like YouTube or Khan Academy, which cover various topics in automotive electronics. o Instructional videos from automotive electronics manufacturers, demonstrating the use of specific tools or components.

- 3. 2. Software Simulations: o Circuit simulation software like Multisim or LTspice, which can be used for designing and testing electronic circuits in a virtual environment. o Automotive diagnostic software tools that provide a hands-on experience with engine control and diagnostic systems. 3. Industry Reports: o Latest industry reports from automotive research organizations or consultancies, which provide insights into current trends and future directions in automotive electronics. 4. Guest Lectures and Webinars: o Inviting industry experts for guest lectures or participating in webinars focused on automotive electronics and emerging technologies in the field. 5. Case Studies: o Collection of case studies illustrating real-world problems and solutions in automotive electronics, which can be great for classroom discussions and understanding practical applications. 6. Workshops and Seminars: o Participating in or organizing workshops and seminars that offer hands-on experience with the latest tools and technologies in automotive electronics. 7. Interactive Learning Modules: o Online learning modules or e-learning courses that offer interactive content, quizzes, and practical exercises in automotive electronics. 8. Technical Magazines and Journals: o Subscriptions to technical magazines and journals that focus on automotive technology and electronics for keeping up-to-date with industry developments. Course Requirements ` Major Examinations Prelim --------------------------- 15% Mid-Term Exam. ------------- 15% Final Exam. ------------------- 30% Quizzes & Recitation -------------- 20% Attendance- -------------------------- 10% Project -------------------------------- 20% TOTAL 100% Teacher

- 4. Desired Learning Outcome Learning Content Teaching and Learning Activities Instructional Materials and References Assessment Tasks and Tool Evidence of Outcomes Time Allotment A. Understand the basic principles of automotive electronics including current, voltage, resistance, and the functionality of basic electronic components. B. Fundamentals of Electricity: a. Concept of Electric Current: Understanding the flow of electric charges in a conductor and its measurement in amperes. b. Voltage: Exploring voltage as the potential difference that causes current to flow in a circuit. c. Resistance: Examining how materials resist the flow of current, measured in ohms, and factors affecting resistance. C. Ohm’s Law: a. Relationship between voltage, current, and resistance. 1. Interactive Lectures: o Use visual aids, like PowerPoint presentations, to explain concepts like current, voltage, and resistance. o Incorporate real- life examples and case studies to illustrate how these principles apply in automotive electronics. 2. Demonstrations: o Live demonstrations using basic electronic components (resistors, capacitors, diodes, etc.) to show their functionality. Instructional Materials: 1.Textbooks: o "Automotive Electronics Handbook" by Ronald K. Jurgen – A comprehensive guide covering all aspects of automotive electronics. o "Understanding Automotive Electronics: An Engineering Perspective" by William B. Ribbens – Focuses on the engineering aspects of automotive electronics. 2.Laboratory Manuals: Assessment Tasks: 1.Quizzes and Exam: o Regular Quizzes: Short quizzes covering key concepts from recent lectures. o Preliminary Exam: Comprehensive written exams testing understanding of current, voltage, resistance, and functionality of electronic components, along with their automotive applications. 2.Laboratory Assignments: 1. Exam and Quiz Results: o Score Reports: Aggregate and individual scores from exams, quizzes, and other written assessments. These demonstrate understanding of theoretical concepts like current, voltage, resistance, and electronic components. o Trend Analysis: Analysis of scores over time to identify learning curves and areas where the class 1. Lecture Time: o Introduction to Basic Principles: 1 hour to introduce current, voltage, resistance, and their significance in automotive electronics. o Detailed Explanation of Each Concept: Current: 30 minutes Voltage: 30 minutes Resistance: 30 minutes o Overview of Basic Electronic Components: 1 hour covering resistors, capacitors, inductors, diodes, and transistors.

- 5. b. Practical applications in automotive circuits. D. Basic Electronic Components and their Functionality: a. Resistors: Role in controlling current flow, different types (fixed, variable), and power rating. b. Capacitors: Function in storing and releasing energy, applications in filtering and smoothing voltage fluctuations. c. Inductors: Understanding magnetic fields in inductors and their use in automotive electronics. d. Diodes: Allowing current to flow in one direction, applications in rectification and voltage regulation. e. Transistors: Amplification and switching o Use of automotive components like sensors and actuators to demonstrate real- world applications. 3. Hands-on Laboratory Work: o Circuit Building: Students construct simple circuits to understand series and parallel configurations. o Experiments with Multimeters: Practical exercises to measure current, voltage, and resistance in different circuits. o Component Testing: Identifying and testing various electronic components on a breadboard or in a car. 4. Group Projects: o Specific manuals detailing lab experiments related to basic electronic components, circuit building, and automotive applications. 3.Software Tools: o Circuit simulation software like Multisim or LTspice for designing and testing electronic circuits. o Automotive diagnostic software for practical training in vehicle electronic systems. 4.Visual Aids: o PowerPoint slides for lectures. o Schematic diagrams and wiring blueprints of automotive electrical systems. o Practical Exercises: Assessing hands-on skills in building and testing circuits, using diagnostic tools, and identifying components. o Lab Reports: Written reports detailing the procedure, observations, and conclusions from laboratory experiments. 3.Project Work: o Group Projects: Designing and implementing a small-scale automotive electronic system or circuit. Evaluation based on design, implementation, may need additional support. 2. Laboratory Reports and Practical Assessments: o Lab Reports: Compiled lab reports showcasing hands-on skills in building circuits, using tools, and understanding automotive electronic components. o Practical Skills Evaluation: Records of practical assessments, demonstrating proficiency in handling and applying electronic concepts in a lab setting. o Interactive Q&A Sessions: 30 minutes for addressing any student queries and reinforcing understanding. Total Lecture Time: Approximately 4 hours 2. Laboratory Time: o Hands-on Introduction to Components: 1 hour for familiarizing students with different electronic components. o Basic Circuit Assembly Exercises: 2 hours focused on constructing simple circuits to demonstrate the principles of

- 6. applications, importance in control circuits. E. Circuit Analysis: a. Understanding series and parallel circuits. b. Calculating total resistance, voltage drops, and current flow in different circuit configurations. F. Automotive- Specific Electronic Components: a. Sensors: Role in monitoring various parameters like temperature, pressure, and position. b. Actuators: Devices that convert electrical signals into physical actions, e.g., fuel injectors. c. Microcontrollers: Basics of how these control various functions in modern vehicles. o Assign small groups to design a basic automotive electronic circuit, encouraging collaboration and problem-solving. 5. Interactive Simulations: o Utilize software like LTspice for circuit simulation, allowing students to visualize and modify circuit behavior digitally. 6. Class Discussions and Q&A Sessions: o Foster a collaborative environment where students are encouraged to ask questions and discuss concepts. o Case-based discussions focusing on common automotive electronic issues. 5.Videos and Tutorials: o Educational videos explaining basic electronics concepts and automotive applications. o Online tutorial platforms (e.g., Khan Academy, YouTube) for supplementary learning. 6.Hardware Kits: o Electronic component kits for practical exercises in labs. o Basic tools like multimeters, soldering irons, and hand tools for circuit construction and diagnostics. References: 1.Journals and Research Papers: and presentation. o Individual Projects: Research or design projects focusing on a specific area of automotive electronics. 4.Class Participation: o Active participation in class discussions, Q&A sessions, and group activities. 5.Case Study Analysis: o Analysis of real-world automotive electronics problems and proposing solutions or improvements. Assessment Tools: 3. Project Submissions: o Final Projects: Evidence from group or individual projects, including design documents, implementation details, and presentations. These highlight applied knowledge and problem- solving skills in automotive electronics. 4. Class Participation Records: o Participation Logs: Records of student participation in class discussions, activities, and Q&A sessions, indicating engagement current, voltage, and resistance. o Testing and Measurement Exercises: 1 hour for practicing measurements using tools like multimeters. o Lab Discussion and Review: 1 hour to discuss outcomes, common issues, and application in automotive systems. Total Laboratory Time: Approximately 5 hours Total Time Allocation: 9 Hours This time allocation ensures that students have a solid grasp of the

- 7. G. Introduction to Automotive Electrical Systems: a. Overview of the vehicle's electrical system, including the battery, alternator, and starter motor. b. Understanding the wiring diagrams and symbols commonly used in automotive electronics. H. Safety Precautions: a. Safe handling of electrical components. b. Understanding the risks involved in working with automotive electrical systems. I. Practical Exercises: a. Hands-on experiments with basic circuits to reinforce theoretical knowledge. b. Use of multimeters and other diagnostic tools to measure voltage, current, and 7. Flipped Classroom: o Assign video tutorials or reading materials for home study, followed by class sessions focusing on problem- solving and application. 8. Guest Lectures: o Invite industry professionals to speak about current trends and technologies in automotive electronics. 9. Workshops: o Conduct workshops focusing on specific skills like soldering, using diagnostic tools, or reading wiring diagrams. 10. Quizzes and Interactive Assessments: o Regular short quizzes to o Access to automotive electronics journals and research papers from databases like IEEE Xplore or SAE International. 2.Online Resources: o Websites and forums dedicated to automotive electronics, offering real- world insights and troubleshooting tips. 3.Industry Standards and Publications: o Publications from organizations like the Institute of Electrical and Electronics Engineers (IEEE) or the Society of Automotive Engineers (SAE) for industry 1.Written Test Tools: o Test papers for quizzes and exams. o Online platforms (e.g., Google Classroom, Moodle) for conducting and grading online tests. 2.Laboratory Tools: o Checklists or rubrics for evaluating lab assignments and reports. o Practical test setups for assessing hands-on skills. 3.Project Assessment Tools: o Rubrics detailing criteria for evaluating the design, implementation, and comprehension. 5. Case Study Analyses: o Completed Case Studies: Documented analysis of automotive electronics case studies, demonstrating application of theoretical knowledge to real-world scenarios. 6. Feedback and Reflections: o Student Feedback: Surveys or feedback forms assessing the course content, teaching methods, and overall learning experience. o Self-Reflection Reports: Students' self- reflections on fundamental concepts before moving on to more complex topics. The balance between lectures and labs allows for both theoretical understanding and practical application.

- 8. resistance in automotive circuits. reinforce key concepts and ensure understanding. o Interactive assessments using platforms like Kahoot or Quizlet. 11. Field Trips: o Visits to automotive workshops or electronics manufacturing facilities to observe the practical application of learned concepts. standards and practices. 4.Supplier Catalogs and Manuals: o Catalogs from automotive electronics suppliers (e.g., Bosch, Delphi) for specific component information. 5.Professional Magazines: o Subscriptions to magazines like "Automotive Engineer" or "Electronics Weekly" for updates on the latest industry trends. 6.Guest Speaker Presentations: o Notes or presentations from guest speakers specializing in teamwork, and presentation of projects. 4.Participation Tracking: o Attendance records. o Records of contributions in class discussions and activities. 5.Case Study Evaluation Tools: o Rubrics for assessing the thoroughness, analytical skills, and problem- solving abilities demonstrated in case study analyses. 6.Feedback Mechanisms: o Tools for providing feedback on assignments and tests, such as LMS (Learning their learning journey, challenges faced, and skills acquired. 7. Portfolio of Work: o Electronic Portfolio: A collection of students' work throughout the course, including projects, lab work, and assignments, which can serve as a comprehensive showcase of their learning and skills. 8. Attendance Records: o Consistency in Engagement: Attendance data as an indicator of student commitment and regular

- 9. automotive electronics. Management System) feedback features or one- on-one meetings. engagement with the course material. Analyzing and Presenting the Evidence: Performance Dashboards: Create visual dashboards showing key metrics like average scores, participation rates, and project success rates. Progress Reports: Detailed reports for each student, highlighting their strengths, areas for improvement, and overall progress. Course Review

- 10. Meetings: Regular meetings with fellow educators or department heads to review the evidence and discuss potential curriculum adjustments or interventions. B. Acquire practical skills in using electronic tools and equipment relevant to automotive technology. 1.Introduction to Tools and Equipment: o Overview of common electronic tools used in automotive technology, including multimeters, oscilloscopes, soldering irons, wire strippers, pliers, and screwdrivers. o Basic principles of operation and safety guidelines for each tool. 2.Multimeters: o Understanding different types of multimeters (analog and digital). 1. Interactive Demonstrations: o Tool Demonstrations: Showcasing each tool's functionality, handling techniques, and safety measures. o Equipment Use Demos: Displaying how to operate diagnostic equipment like multimeters and oscilloscopes. 1. Laboratory Manuals: o Detailed guides for laboratory exercises, including circuit building, soldering, and using diagnostic tools. o Step-by-step procedures for common diagnostic tests and equipment usage. 2. Tool and Equipment Guides: 1.Practical Lab Exercises: o Task-Based Assessments: Students perform specific tasks such as soldering a connection, measuring voltage, or diagnosing a circuit issue, and are graded based on accuracy and technique. 1. Performance in Practical Lab Exercises: o Lab Reports and Exercise Sheets: Documentation of completed lab exercises, including details of tasks performed, tools used, results obtained, and student interpretations. o Video Recordings: In some cases, 1. Laboratory Sessions: o Allocate 2 to 3 hours per week for hands-on laboratory work. o Within each session, divide time between demonstrations, actual practice, and review. 2. Tool and Equipment Familiarization: o Dedicate initial 1 to 2 sessions (2-3 hours each) solely to

- 11. o How to measure voltage, current, resistance, and continuity in automotive circuits. o Interpretation of readings and troubleshooting using multimeter data. 3.Oscilloscopes: o Basics of oscilloscope operation, including setting up and reading waveforms. o Applications in diagnosing issues in automotive electronic signals. 4.Soldering Techniques: o Fundamentals of soldering, including soldering safety. o Practice sessions on soldering and desoldering components on circuit boards. 5.Circuit Building and Testing: o Hands-on exercises in constructing basic automotive electronic circuits. 2. Hands-On Laboratory Sessions: o Circuit Building Workshops: Practical sessions where students build and test circuits using the tools they've learned about. o Soldering Practice: Supervised exercises in soldering and desoldering components, emphasizing proper technique and safety. 3. Group Projects: o Diagnostic Challenges: Assigning small groups to diagnose and fix issues in automotive electrical systems using various tools. o Manuals and user guides for each piece of electronic equipment and tool, including multimeters, oscilloscopes, soldering stations, and OBD-II scanners. 3. Circuit Diagrams and Schematics: o Collections of automotive electronic circuit diagrams for practice and reference. o Schematic symbols and reading exercises to familiarize students with automotive electrical schematics. 4. Safety Protocol Documents: o Circuit Building and Testing: Students construct and test electronic circuits, assessed on correctness and functionality. 2.Diagnostic Scenarios: o Problem- Solving Tasks: Presenting students with a malfunctioning automotive electronic scenario. They must diagnose the problem and suggest solutions using appropriate tools. o Role-Playing: Students take on roles (e.g., technician, diagnostician) video recordings of lab sessions can serve as evidence of hands-on skills. 2. Assessment Results: o Graded Assignments: Scores from practical assignments and tool proficiency tests. o Project Evaluations: Grades and feedback on individual and group projects, focusing on the application of skills in using electronic tools. 3. Diagnostic Test Outcomes: o Scenario-Based Assessments: Records of students’ performance in diagnostic scenarios, introducing and familiarizing students with the tools and equipment. o Include basic operations, safety procedures, and care/maintenance of tools. 3. Practical Exercises and Circuit Building: o Following sessions (4-6 hours) can focus on practical exercises like building simple circuits, using multimeters, and practicing soldering. o Include both guided exercises and open-ended projects where students apply skills independently.

- 12. o Testing and troubleshooting circuits using various diagnostic tools. 6.Use of Diagnostic Equipment: o Introduction to specialized automotive diagnostic equipment, such as OBD-II (On- Board Diagnostics) scanners. o Simulations or practical sessions on diagnosing common automotive electronic issues. 7.Wiring and Harnesses: o Understanding automotive wiring diagrams. o Practice in creating and repairing wiring harnesses. 8.Electronic Control Units (ECUs): o Basics of ECUs in modern vehicles. o Demonstration of ECU programming and configuration basics. 9.Sensors and Actuators: o Identifying and testing various sensors and o ECU Programming Exercises: Working in teams to understand basic ECU programming and configuration. 4. Simulation Exercises: o Virtual Diagnostics: Using software simulations to practice diagnostic procedures and understand the use of diagnostic tools. 5. Field Trips and Experiential Learning: o Visits to automotive repair shops or manufacturing facilities to observe professional use of electronic tools and equipment. o Detailed safety guidelines for handling electronic tools and working within an automotive lab environment. 5. Video Tutorials: o Access to high- quality instructional videos demonstrating the use of various tools and equipment. 6. Software for Simulation: o Licenses for circuit simulation software (e.g., Multisim, LTspice) and diagnostic software tools. References: 1. Textbooks: to solve real- life automotive electronic problems. 3.Tool Proficiency Tests: o Equipment Handling: Assessing students' ability to correctly and safely use electronic tools like multimeters, oscilloscopes, and diagnostic scanners. o Accuracy and Precision Tests: Evaluating the precision of measurements and diagnostics performed by students. 4.Project Work: highlighting their problem- solving and diagnostic abilities. 4. Observation Records: o Instructor Observations: Notes and comments from instructors during lab sessions and practical exercises, focusing on skill execution, accuracy, and safety compliance. o Peer Review Feedback: Insights from peer assessments, providing an alternative perspective on students' practical skills. 5. Safety Protocol Adherence: 4. Diagnostic and Troubleshooting Skills: o Allocate 3 to 4 sessions (2-3 hours each) to develop diagnostic skills using equipment like oscilloscopes and diagnostic scanners. o Incorporate real- life simulation scenarios or case studies for problem-solving. 5. Project Work: o Assign a long- term project (spanning over several weeks) where students apply various skills learned. Dedicate around 1 to 2 hours per week for project work and consultations. 6. Review and Feedback:

- 13. actuators found in vehicles. o Practical exercises in replacing or servicing these components. 10. Safety Practices: o Emphasizing safety in handling electronic tools and working with automotive electrical systems. Supplementary Learning: Workshop Visits: Organized visits to automotive workshops or dealerships for real- world exposure. Guest Lectures: Sessions by industry professionals sharing practical insights and experiences. 6. Role-Playing and Scenario- Based Learning: o Creating real-life scenarios where students must use their skills to solve automotive electronics issues. 7. Interactive Quizzes and Games: o Online quizzes or in-class games focusing on tool identification, usage, and safety. 8. Peer Teaching: o Advanced students or those with prior experience can share their knowledge and tips with their peers. 9. Workshops by Industry Professionals: o Inviting experts to conduct specialized workshops on the o "Automotive Technology: A Systems Approach" by Jack Erjavec and Rob Thompson – A comprehensive guide that includes sections on electronic diagnostics and tool usage. o "Automotive Electrical and Engine Performance" by James D. Halderman – Offers insights into the use of diagnostic tools in automotive technology. 2. Online Resources: o Websites, forums, and online communities focused on automotive o Team Projects: Students work in groups on a project that involves using various electronic tools and equipment, assessed on teamwork, application of skills, and project outcome. o Individual Projects: Independent projects focusing on a specific tool or diagnostic technique. 5.Safety and Protocol Compliance: o Safety Assessment: Evaluating students’ adherence to safety o Safety Checklist Compliance: Documentation showing students’ adherence to safety protocols and procedures during lab work. 6. Student Reflections and Self- Assessments: o Reflective Journals: Students' self- reflection on their learning process, challenges faced, skills learned, and areas for improvement. o Feedback Forms: Students' feedback on the learning experience, which can provide insights o Regular short sessions (30 minutes to 1 hour) after practical exercises for reviewing work, providing feedback, and discussing common issues or challenges. 7. Assessment and Testing: o Reserve 1 to 2 sessions (2-3 hours each) towards the end of the module for practical assessments, testing the proficiency in using tools and equipment. Total Time Allocation Approximate Total Hours: 25-30 hours spread over the

- 14. latest tools and technologies in automotive electronics. 10.Case Studies and Problem- Solving Sessions: o Analyzing real- world cases to understand the application of tools in specific automotive electronic situations. 11.Feedback and Reflective Sessions: o Regular sessions for students to reflect on their learning, discuss challenges, and receive feedback. Supplemental Activities: Video Tutorials: Access to high- quality video tutorials for electronics and diagnostics. o Manufacturer websites for specific tools and equipment, offering additional resources and FAQs. 3. Industry Journals and Magazines: o Subscriptions to relevant publications like "Automotive Engineer" or "Electronics Weekly" that provide updates on the latest tools and technologies. 4. Supplier Catalogs: o Catalogs from suppliers of automotive electronics tools and equipment, providing specifications protocols while handling electronic tools and equipment. Assessment Tools: 1.Rubrics and Checklists: o Detailed rubrics for each practical task, outlining criteria for successful completion and proficiency levels. o Checklists for safety procedures and correct tool usage. 2.Observational Assessments: o Instructors observe and grade students during lab exercises and into the effectiveness of the practical sessions. 7. Portfolios: o Electronic Portfolios: A collection of students' work, including lab reports, project documentation, and other relevant materials, showcasing their progression and competency in practical skills. 8. Attendance and Participation Records: o Lab Attendance: Consistent attendance in lab sessions as an indicator of engagement and practice opportunity. o Active Participation: semester/course duration. Flexibility: Allow some flexibility in the schedule for extended exercises or additional practice as needed. Supplemental Learning Self-Study and Practice: Encourage students to spend additional time outside of scheduled sessions for practice and review. Online Tutorials: Recommend online resources or tutorials for additional

- 15. additional out-of- class learning. Discussion Forums: Online platforms where students can discuss challenges and share experiences related to using electronic tools. and usage information. 5. Professional Guides and Standards: o Publications from organizations like SAE International or IEEE detailing standards and best practices in automotive electronics. 6. Case Studies: o Collection of real-world case studies illustrating the application of diagnostic tools in solving automotive electronic issues. Supplementary Materials: Workshop Manuals: Specific to certain vehicle diagnostic scenarios based on their technique, problem- solving approach, and final outcomes. 3.Peer Reviews: o Structured peer assessments, where students evaluate each other’s work in lab exercises and projects. 4.Written Reports: o Students submit reports on lab exercises and projects, detailing the process, findings, and conclusions. 5.Digital Tools: o Utilizing digital platforms to Records of active participation and engagement in practical sessions and workshops. Analyzing and Presenting the Evidence Data Compilation: Aggregating scores, feedback, and observations into a comprehensive report or dashboard. Performance Trends: Analyzing trends over time to identify areas of improvement or particular strengths. Course Review Meetings: Discussing the learning opportunities.

- 16. models, these manuals can provide insights into practical aspects of automotive electronics. Interactive Learning Modules: Online modules that offer interactive learning experiences about tool usage and diagnostics. submit and assess reports, projects, and peer reviews. o Video recordings of practical tasks for later evaluation, particularly useful for remote learning scenarios. 6.Feedback Forms: o Forms for students to reflect on their learning process and for instructors to provide constructive feedback on performance. collected evidence with teaching staff or program coordinators to evaluate the efficacy of the practical components of the course.

- 17. C. Gain knowledge of the design and operation of automotive electronic systems like the ignition system and ECM. 1.Overview of Automotive Electronic Systems: o Introduction to the role and importance of electronics in modern vehicles. o General layout and components of automotive electronic systems. 2.The Ignition System: o Basic Principles: Understanding the purpose and fundamental operation of the ignition system. o Components: Detailed study of ignition system components such as spark plugs, ignition coils, distributors, and ignition modules. o Types of Ignition Systems: Conventional Ignition Systems: Understanding mechanical contact breaker points. Electronic Ignition Systems: Studying transistorized ignition 1.Interactive Lectures: o Theoretical Instruction: Detailed lectures on the principles of ignition systems and ECM operation, using visual aids like diagrams and animations. o Guest Speakers: Inviting industry professionals or technicians to provide real- world insights into the latest technologies and trends in automotive electronics. 2.Practical Demonstrations: o Live Demonstrations: Showcasing components of ignition systems and ECMs, explaining their 1.Textbooks and Manuals: o "Automotive Technology: A Systems Approach" by Jack Erjavec and Rob Thompson – Covers in-depth concepts of automotive electronics including ignition systems and ECMs. o "Understanding Automotive Electronics" by William B. Ribbens – Provides an overview of electronic control systems in vehicles. o Manufacturer- specific service manuals – Detailed guides on specific vehicle models, focusing on 1.Written Examinations: o Multiple-choice, short answer, and essay questions covering the principles, components, and operation of ignition systems and ECMs. o Case-study- based questions that require students to apply their knowledge to real-world scenarios. 2.Practical Laboratory Assessments: o Hands-on tasks where students demonstrate their ability to work with ignition systems and ECMs, including diagnostics and troubleshooting. 1.Exam and Quiz Results: o Detailed scores and feedback from written exams and quizzes that assess understanding of the ignition system and ECM. o Analysis of results to identify trends, strengths, and areas needing improvement. 2.Laboratory Reports and Assessments: o Compiled lab reports demonstrating hands-on work with automotive electronic systems. o Graded assessments of practical exercises, highlighting 1.Lecture Time: o Introduction to Automotive Electronic Systems: 2 hours for a general overview of automotive electronics, focusing on their importance and role in modern vehicles. o Detailed Study of Ignition Systems: 4 hours divided over multiple sessions, covering types of ignition systems, components, and their functionality. o Engine Control Module (ECM) Concepts: 4 hours focused on the architecture, components, and operation of ECMs. o Sensor and Control Strategies: 3

- 18. components and operations. Distributorless Ignition Systems: Learning about direct ignition and coil- on-plug systems. o Ignition System Diagnostics: Techniques for diagnosing and troubleshooting common ignition system problems. 3.Engine Control Module (ECM): o Function of ECM: Exploring how the ECM controls various engine functions and vehicle subsystems. o Components and Architecture: Understanding the internal components of an ECM, including microprocessors, memory, and input/output interfaces. o Sensor Inputs: Studying various sensors that feed information to the ECM, such as oxygen sensors, temperature sensors, and MAP sensors. functions and interrelations. o Simulation Demonstrations: Using software to simulate the operation of ignition systems and ECMs, visualizing data flow and control processes. 3.Hands-On Laboratory Work: o Circuit Experiments: Building and testing circuits related to ignition systems in a controlled lab environment. o ECM Diagnostics: Practicing with diagnostic tools to understand ECM functions, error codes, and troubleshooting procedures. 4.Group Projects: their electronic systems. 2.Laboratory Workbooks: o Workbooks containing lab exercises and projects related to automotive ignition systems and ECM operations. 3.Circuit Diagrams and Schematics: o Collections of circuit diagrams and schematics for various types of automotive electronic systems. 4.Software Tools: o Automotive diagnostic software for ECM analysis and troubleshooting. o Circuit simulation software to o Practical tests on identifying components, understanding their functions, and performing basic adjustments or configurations. 3.Project Work: o Assigning projects where students design a basic ignition system or simulate ECM functions, evaluated on criteria like accuracy, creativity, and application of theoretical knowledge. 4.Presentations: o Students present their projects or case study analyses, demonstrating their understanding and ability to proficiency in diagnostics and system operations. 3.Project Documentation and Reviews: o Final reports and presentations for projects related to ignition systems and ECMs, showcasing depth of understanding and application of knowledge. o Instructor and peer reviews of these projects, providing qualitative and quantitative feedback. 4.Performance in Practical Tests: o Records of performance in practical tests, including diagnostics, troubleshooting, hours discussing various sensors, inputs, and control strategies used by ECMs. o Diagnostics and Troubleshooting: 2 hours dedicated to diagnostic techniques and problem-solving for ignition systems and ECMs. Total Lecture Time: Approximately 15 hours 2.Laboratory and Practical Sessions: o Hands-On with Ignition Systems: 3 hours of lab work practicing with ignition system components and testing. o ECM Diagnostics: 4

- 19. o Control Strategies: Learning about fuel injection control, ignition timing control, and emission control systems managed by the ECM. o Diagnostics and Reprogramming: Methods for diagnosing ECM issues and the basics of reprogramming or updating ECM software. 4.Electronic Fuel Injection (EFI) System: o Understanding the components and operation of EFI systems. o Studying the role of the ECM in fuel injection control. 5.Vehicle Networking and Communication Systems: o Basics of automotive communication protocols like CAN (Controller Area Network). o How ECM interfaces with other electronic modules in the vehicle. 6.Safety and Reliability: o System Design Projects: Assigning groups to design a basic electronic ignition system or simulate ECM operations, encouraging collaborative learning and problem-solving. o Case Study Analysis: Working in groups to analyze and present solutions for real- life case studies involving ignition systems and ECMs. 5.Workshops and Seminars: o Conducting specialized workshops focusing on specific aspects like ECM programming, sensor integration, or model and test ignition system circuits. 5.Video Tutorials: o Educational videos demonstrating the workings of ignition systems and ECMs. o Online platforms like YouTube or specialized automotive education channels offering relevant content. 6.PowerPoint Presentations: o Slideshows for lectures, covering key concepts, diagrams, and case studies. References communicate complex concepts. 5.Group Assessments: o Group projects focusing on collaborative problem-solving in automotive electronic system scenarios. 6.Quizzes and In- Class Assignments: o Short quizzes and assignments throughout the course to continually assess understanding and retention of key concepts. Assessment Tools 1.Test Papers and Online Quizzes: and use of automotive electronic tools. 5.Case Study Analyses: o Submissions and evaluations of case study analyses that involve ignition systems and ECMs, demonstrating applied knowledge and problem-solving skills. 6.Class Participation Records: o Documentation of participation in discussions, workshops, and group activities, indicating engagement and understanding. 7.Self-Assessment and Reflections: o Students' self- assessments and reflective essays hours in the lab working with ECMs, including diagnostics and basic programming or configuration. o Case Study Implementation: 2 hours for practical case study exercises related to these systems. o Project Work: 3 hours allocated for project work, where students can apply their knowledge in a practical setting. Total Lab/Practical Time: Approximately 12 hours 3.Review and Feedback Sessions: o Mid-Course Review: 1 hour to discuss progress,

- 20. o Discussion on the safety aspects and reliability concerns of automotive electronic systems. 7.Case Studies: o Analyzing real-world case studies involving ignition system and ECM diagnostics and repairs. 8.Practical Applications: o Hands-on exercises or simulations in diagnosing and working with ignition systems and ECMs. Supplemental Learning: Software Simulations: Use of diagnostic software to simulate ECM operations and troubleshooting. Guest Lectures: Sessions from automotive electronics experts or technicians specializing in ignition systems and ECMs. Workshop Visits: Practical exposure through visits to advanced diagnostics. 6.Interactive Simulation and Software Use: o Utilizing automotive diagnostic software and simulation tools for students to virtually experience and manipulate ignition systems and ECM operations. 7.Field Trips: o Visiting automotive service centers or manufacturing plants to observe real-world applications and maintenance of these systems. 8.Class Discussions and Q&A Sessions: o Facilitating discussions on lecture topics and 1.Technical Journals and Articles: o Access to automotive electronics journals and trade publications for current research and developments. o IEEE and SAE International publications for in-depth technical articles. 2.Online Databases and Resources: o Websites and forums dedicated to automotive electronics, offering practical insights, troubleshooting tips, and expert advice. o Traditional paper-based tests or online platforms (like Moodle, Google Classroom) for administering and grading quizzes and exams. 2.Rubrics: o Detailed rubrics outlining specific criteria and performance levels for practical assessments and projects. 3.Laboratory Assessment Sheets: o Checklists or score sheets for evaluating laboratory exercises, ensuring a consistent and objective assessment of practical skills. discussing their learning journey, challenges encountered, and knowledge gained regarding automotive electronic systems. 8.Feedback Surveys: o Summary of feedback from students on the course content, teaching methods, and their perceived understanding of the subject matter. 9.Portfolio of Work: o A comprehensive portfolio that includes all the aforementioned elements, providing a holistic view of each student’s clarify doubts, and reinforce key concepts. o Pre-Assessment Review: 1 hour before any major assessments to ensure readiness and comprehension. Total Review Time: 2 hours Total Time Allocation: Approximately 29 Hours Flexibility: This schedule should be flexible, allowing for adjustments based on student progress and comprehension levels. Additional Activities: Time for guest lectures, workshops, or field trips should be considered

- 21. automotive service centers or factories. current developments in automotive electronics. o Encouraging questions and peer-to-peer explanations to deepen understanding. 9.Case-Based Learning: o Presenting various scenarios or problems related to ignition systems and ECMs for students to solve, fostering analytical and critical thinking. 10. Assessment Quizzes: o Regular short quizzes to reinforce learning and assess understanding of key concepts. 11. Reflective Learning: o Manufacturer websites for technical specifications and updates on ignition systems and ECMs. 3.Case Studies: o Real-world case studies detailing specific scenarios involving ignition system faults or ECM diagnostics. 4.Industry Standards and Guidelines: o Documents from organizations like SAE International or ISO, outlining standards for automotive electronic systems. 5.Supplier and Component Catalogs: o Catalogs from automotive 4.Presentation Evaluation Forms: o Forms or criteria lists for assessing the effectiveness and clarity of student presentations. 5.Peer Evaluation: o Structured peer review forms allowing students to assess each other’s contributions in group projects. 6.Diagnostic Software and Tools: o Using automotive diagnostic software as a tool for students to demonstrate their proficiency in using and interpreting ECM data. learning outcomes. Analyzing and Presenting the Evidence Data Visualization: Graphical representation of exam scores, lab performance, and project evaluations for a clear understanding of student achievements. Performance Dashboards: Creating dashboards that display key metrics and trends over the course duration. Progress Reports: Individual reports that track each student’s progress, separately, depending on availability and relevance.

- 22. o Encouraging students to reflect on what they have learned in each session and how it applies to real- world scenarios. Supplemental Activities: Online Tutorials and Resources: Providing access to online courses or tutorials for additional learning outside of the classroom. Discussion Forums: Creating online forums for students to discuss course material, share insights, and pose questions. electronics suppliers, providing detailed information on components used in ignition systems and ECMs. 6.Guest Lecture Materials: o Notes, slides, and resources from guest lectures by industry professionals. 7.Portfolio Review: o A comprehensive evaluation of a student’s collection of work throughout the course, including lab reports, project documentation, and test scores. highlighting successes and areas for further development. Prepared by: Noted by: Recommending Approval: Approved:

- 23. ALVIN DOMINIC L. PABLO AILEEN A. ALAD-AD, MTTE AILEEN A. ALAD-AD, MTTE ANALYN G. ABDULRAOF, Ph.D. Instructor Program Head, DIT Chairperson, DIT Dean of Instruction