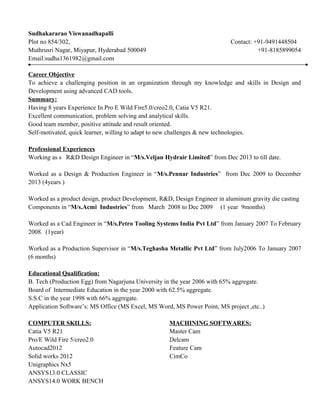

The candidate has over 8 years of experience in design and development using CAD tools like Creo and CATIA. He is currently working as an R&D Design Engineer and has experience working on projects involving cranes, attachments, hydraulic cylinders and other equipment. He aims to achieve a challenging position utilizing his knowledge and skills in design.