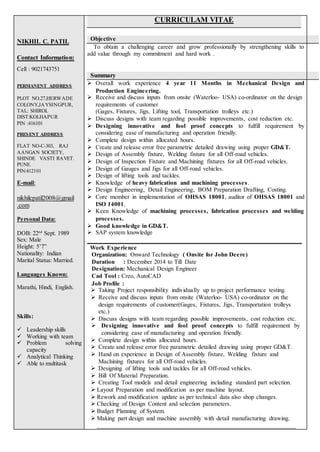

This document is a curriculum vitae for Nikhil Patil. It includes his contact information, personal details like date of birth and marital status. It outlines his educational qualifications which includes a BE in Mechanical Engineering. It describes his work experience of over 4 years as a Mechanical Design Engineer. It lists his skills like leadership, problem solving, and analytical thinking. His objective is to obtain a challenging career where he can strengthen his skills and add value through commitment and hard work.