Chetan Kumar is a senior product design engineer with over 8 years of experience in hardware design. He has expertise in 3D modeling and mechanical drawings. Currently he works at Molex India as a senior product design engineer, where he is responsible for designing testing fixtures and developing new products. Previously he has worked at Tech Mahindra and Solidus Hi Tech, where he led design teams and handled projects involving sheet metal components. He has extensive experience in product development from concept to manufacturing.

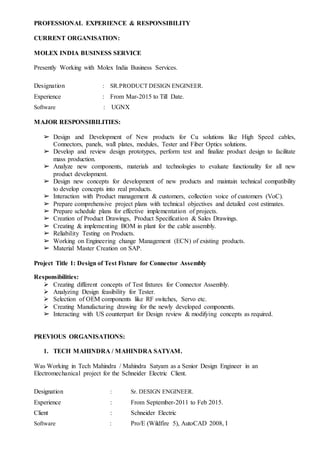

![Designation : NPD Engineer.

Experience : From July-2008 to September 2011.

Department : Design & Development/Manufacturing.

Location : Bangalore.

Software : Pro E, Catia V5, AutoCAD.

MAJOR RESPONSIBILITIES:

➢ Generation of 3D models & 2D drawings considering manufacturing feasibility and

engineering standards for sheet metal operations.

➢ Building sheet metal enclosure prototype based on customer requirement.

➢ Handling Reverse engineering projects & modifying considering manufacturing feasibility.

➢ Selection of materials for sheet metal enclosure development.

➢ Worked on projects which involved engineering design changes (RFC- request for a change).

➢ Worked on projects which involved extensive use of GD&T (Geometrical dimensioning and

tolerance).

➢ Customer Interaction for the Drawing amendment and changes.

➢ Preparing Costing for New RFQ’s & its Development for sheet metal components.

➢ Analyzing production drawings & creation of Process Plans, BOM, Job cards & Route cards

for detail sheet metal parts, Press components, Bus bars & structure assemblies.

➢ Cost Reduction & lead time reduction for existing products.

➢ Preparation of Process flow chart, Control plan, PFMEA& tooling requirement.

➢ Solving practical production & quality problems by communicating with Production team &

Quality team.

Projects Handled

● Design, design modification & Proto Developing of sheet metal parts & assembly of Steering

Mounting System for John Deere Earth Moving Equipments.

● Design, design modification & Proto Developing of sheet metal parts for LV & MV panels

for Schneider Electric & APC.

● Design, design modification and Proto Developing of sheet metal parts & manufacturing of

Chop Saw Base Assembly.

● Creation of Process Plans for Assembly of Proxima UPS Enclosures.

Personal Details:-

Name : Chetan Kumar.R

Date of birth : 07-03-1984

Gender : Male

Father’s name : Rangaiah. R

Marital status : Married

Nationality : Indian

Languages Known : English, Kannada & Hindi,

Passport No : J6529747.

Yours truly,

[CHETAN KUMAR.R]](https://image.slidesharecdn.com/b5590790-eee7-4aee-9e59-b4bcaf25cf0f-170128055448/85/Chetan-Kumar_LR-4-320.jpg)