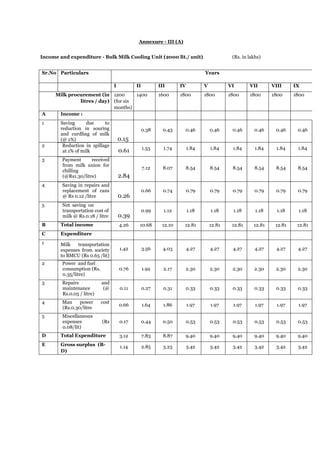

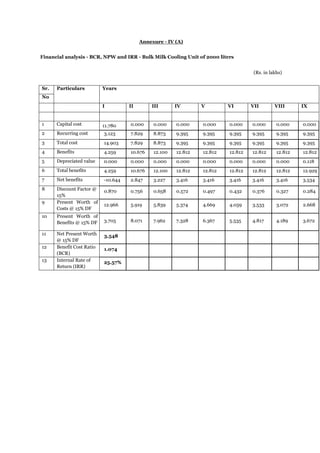

This document provides details on a model bankable project for financing the purchase and installation of bulk milk cooling units. The key points are:

1) Bulk milk cooling units ranging from 500-10,000 liters in capacity immediately cool milk after collection to prevent spoilage and ensure quality. They benefit dairy cooperatives and farmers.

2) The units comprise a cooling tank, generator, weighing equipment, and may include an automatic milk collection unit. Specifications meet BIS standards.

3) Financing the units aims to improve milk quality, increase collection volumes, reduce transportation and storage costs, and benefit dairy development programs across India.