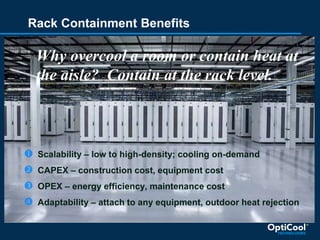

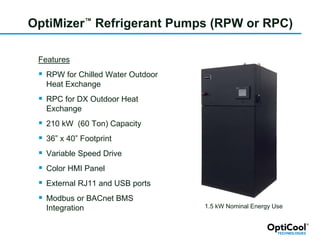

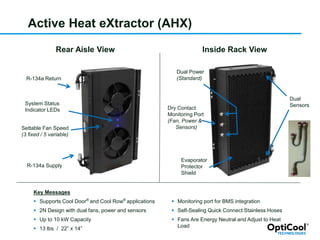

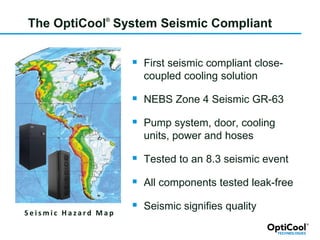

The document discusses rack containment cooling as a future-proof solution for data center cooling. It presents OptiCool as a rack containment system that uses refrigerant-based cooling at the rack level to provide scalable and efficient cooling. Key benefits highlighted include reducing cooling energy usage by 60-95%, allowing for more racks in the same space, eliminating raised floors, and qualifying for energy efficiency subsidies. The system can scale from low to high density loads and is adaptable to any equipment rack. It offers scalability, adaptability, energy efficiency, and space efficiency to future-proof cooling design needs.