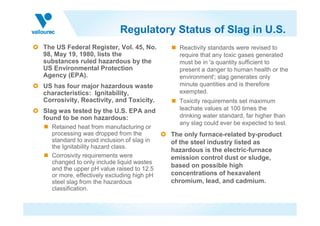

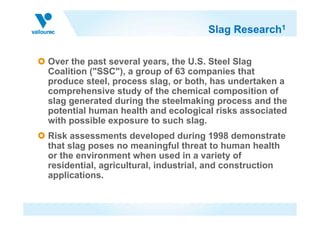

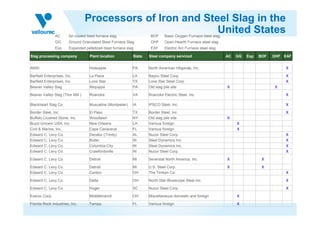

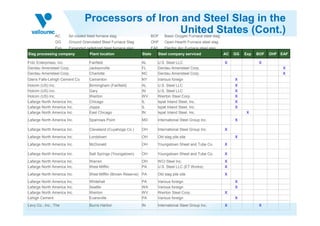

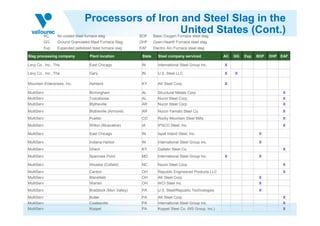

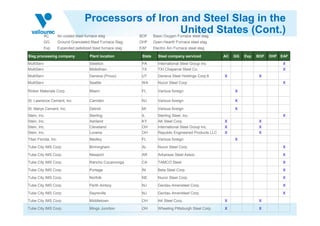

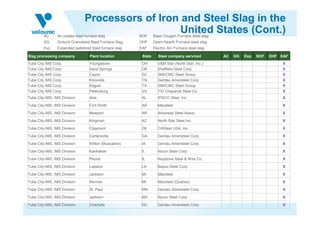

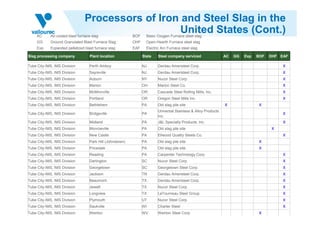

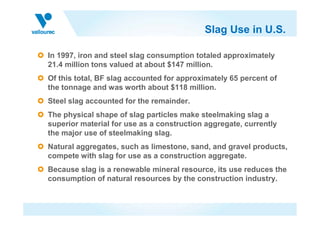

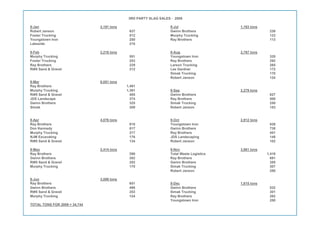

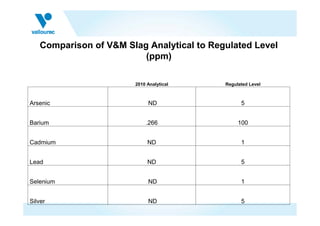

Slag is a byproduct of metal smelting that is produced in large quantities annually. It consists of various metal oxides and other components that float to the top during smelting. In the US, slag was tested and found to be non-hazardous, meeting regulatory standards for ignitability, corrosivity, reactivity, and toxicity. Over 60 companies in the US process slag from steel production and sell it for various residential, agricultural, and industrial uses.