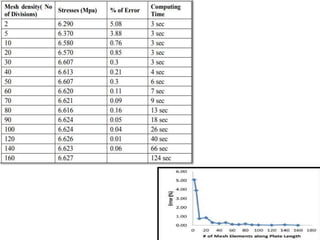

The document discusses various meshing techniques and element quality criteria important for finite element analysis. It describes how to discretize a structure using suitable elements of appropriate shape, size and number. 1D, 2D and 3D element types are introduced along with the importance of element quality parameters like skewness, aspect ratio, warping factor and Jacobian. Maintaining good element quality is crucial for accurate results as degraded elements can underestimate stresses and strains. The document also covers mesh refinement methods and considerations for meshing structures such as handling discontinuities and utilizing symmetry.

![Importance of Element Quality

• The shape of Elements in FE Analysis must be distorted from their Ideal

shapes when meshing the irregular or complex geometric shapes.

• Every element is designed to work properly within a certain range of

shape distortion. Exactly how much distortion and what type of

distortion is allowed before an element degenerate depends on factors

such as element type, numerical procedures used in the element

design, and so forth.

• The Ideal shape of [2D Elements] a triangular element is an equilateral

triangle and a quadrilateral; it is a square.

• The Ideal shape of [3D Elements] a Tetrahedron element is a Regular or

Isosceles Tetrahedron and a Hexahedron, it is a Cube etc.,

• If the actual shape that the element assumes after mapping onto

model geometry differs too much from the natural shape, the element

becomes degenerated and produces erroneous results.](https://image.slidesharecdn.com/unit2-meshingtechniques-230503062007-0002362c/85/Unit-2-Meshing-Techniques-pptx-12-320.jpg)

![A] NODES AT DISCONTINUITIES

In a structure we come across the following types of

discontinuities:

(a) Geometric discontinuity

(b) Discontinuity of Loads

(c) Discontinuity of the Boundary conditions

(d) Material Discontinuity.](https://image.slidesharecdn.com/unit2-meshingtechniques-230503062007-0002362c/85/Unit-2-Meshing-Techniques-pptx-22-320.jpg)

![B] REFINING MESH

To get better results the finite element mesh should be refined in the

following situations

a. To approximate curved boundary of the structure

b. At the places of high stress gradients.

Refined mesh near curved boundary of a

dam](https://image.slidesharecdn.com/unit2-meshingtechniques-230503062007-0002362c/85/Unit-2-Meshing-Techniques-pptx-27-320.jpg)

![C] USE OF SYMMETRY

Wherever there is symmetry in the problem it should be made use. By

doing so lot of memory requirement is reduced or in other words we can

use more elements (refined mesh) for the same capacity of computer

memory. When symmetry is to be used, it is to be noted that at right angles

to the line of symmetry displacement is zero. In the tension bar example

shown in Fig. biaxial symmetry of the problem is utilized and only quarter

of the bar is taken for the analysis.

Discretization of half of Tension Flat](https://image.slidesharecdn.com/unit2-meshingtechniques-230503062007-0002362c/85/Unit-2-Meshing-Techniques-pptx-28-320.jpg)

![D] ELEMENT ASPECT RATIO

The shape of the element also affects the accuracy of

analysis.

Definition - The ratio of largest to smallest size in an

element

The conclusion of many researchers is aspect ratio should

be as close to unity as possible.](https://image.slidesharecdn.com/unit2-meshingtechniques-230503062007-0002362c/85/Unit-2-Meshing-Techniques-pptx-29-320.jpg)

![G] Mesh Quality

In a finite element mesh, it is generally desirable to avoid

elements of high aspect ratio. The presence of such elements

can have adverse effects on the analysis results.

•In general, such elements can influence analysis results, and

lead to misleading and inaccurate results, which are

dependent on the mesh.

•In extreme cases, such elements may even be responsible

for non-convergence of the finite element solution, and the

analysis will be aborted.](https://image.slidesharecdn.com/unit2-meshingtechniques-230503062007-0002362c/85/Unit-2-Meshing-Techniques-pptx-31-320.jpg)

![F] Mesh-geometry association

Creating an association between orphan mesh entities (elements,

element faces, element edges, and nodes) and adjacent geometry,

allows the transfer of loads, interactions, and boundary conditions

from the geometry to the mesh.

Figure 1 shows an example of the use of mesh-geometry association

between a two-dimensional orphan element region and an adjoining

geometric region.](https://image.slidesharecdn.com/unit2-meshingtechniques-230503062007-0002362c/85/Unit-2-Meshing-Techniques-pptx-35-320.jpg)