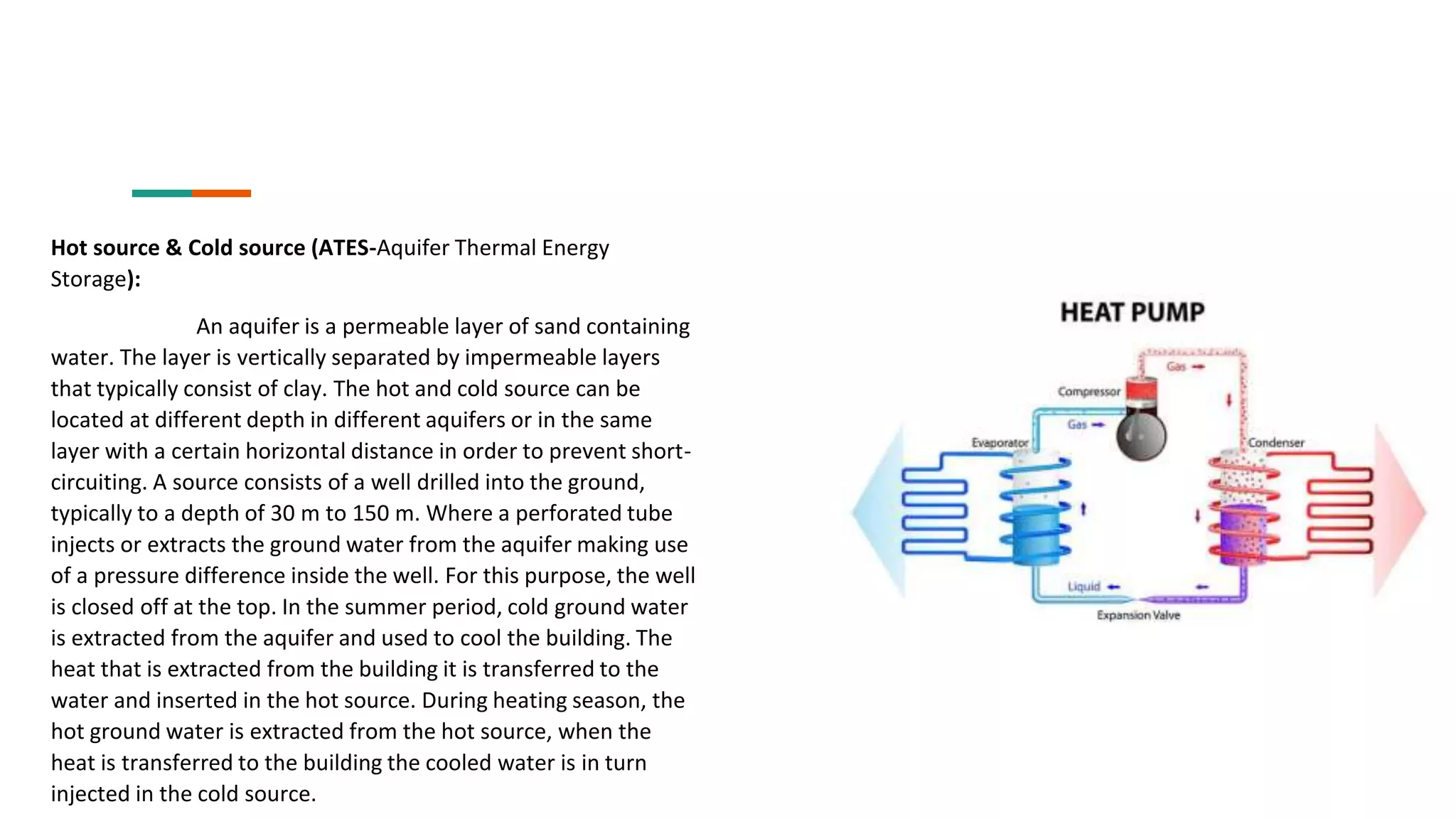

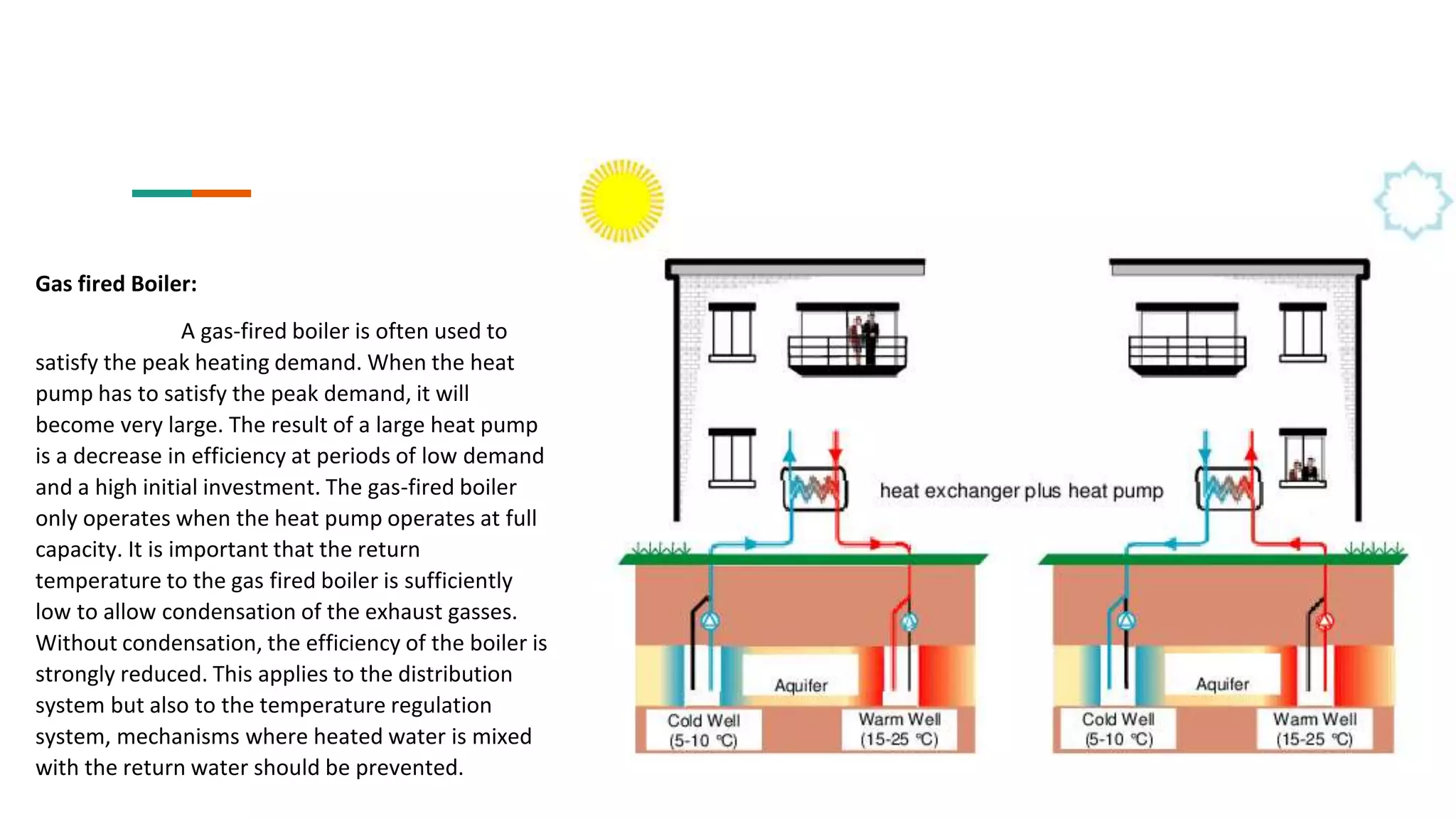

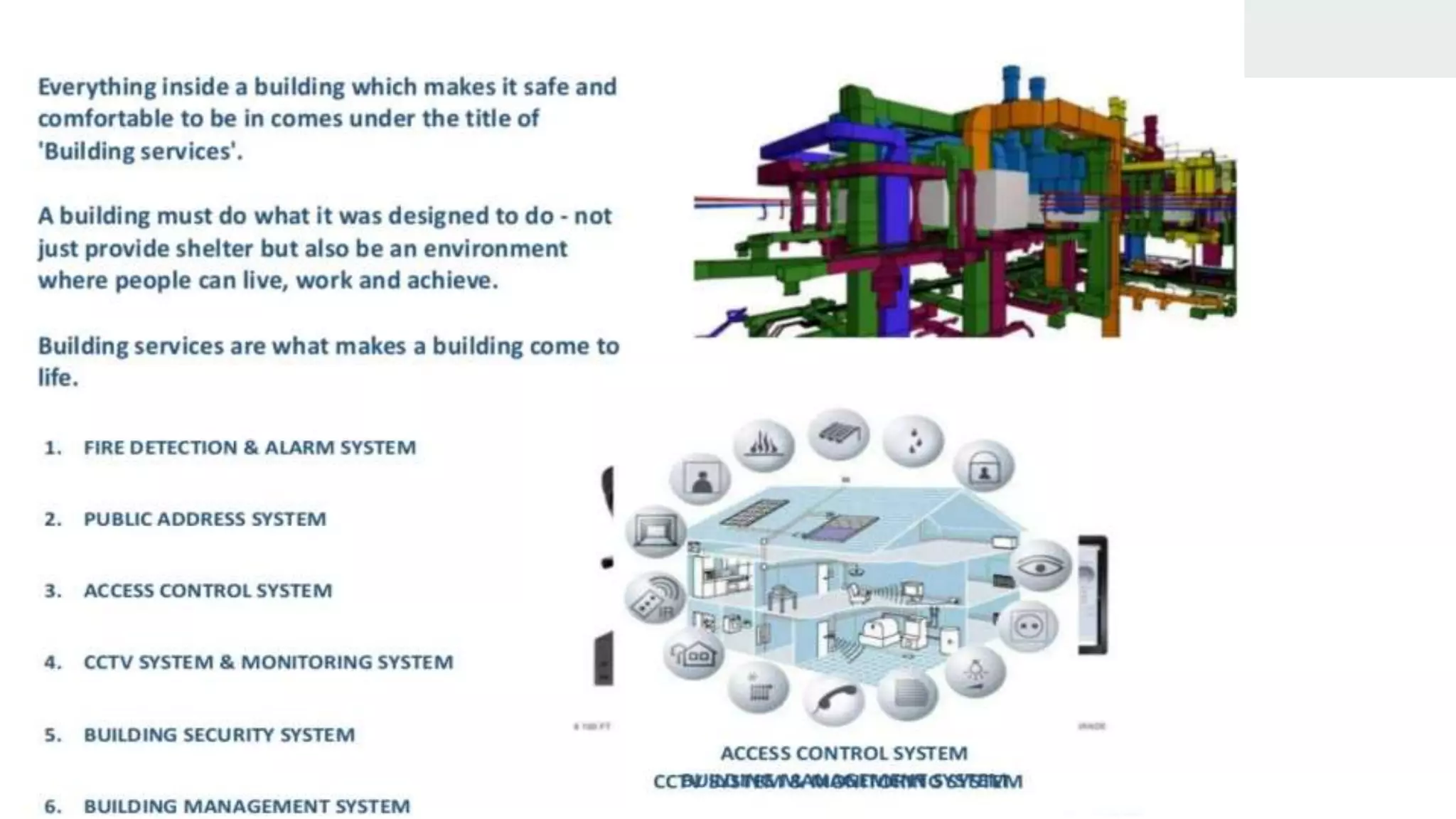

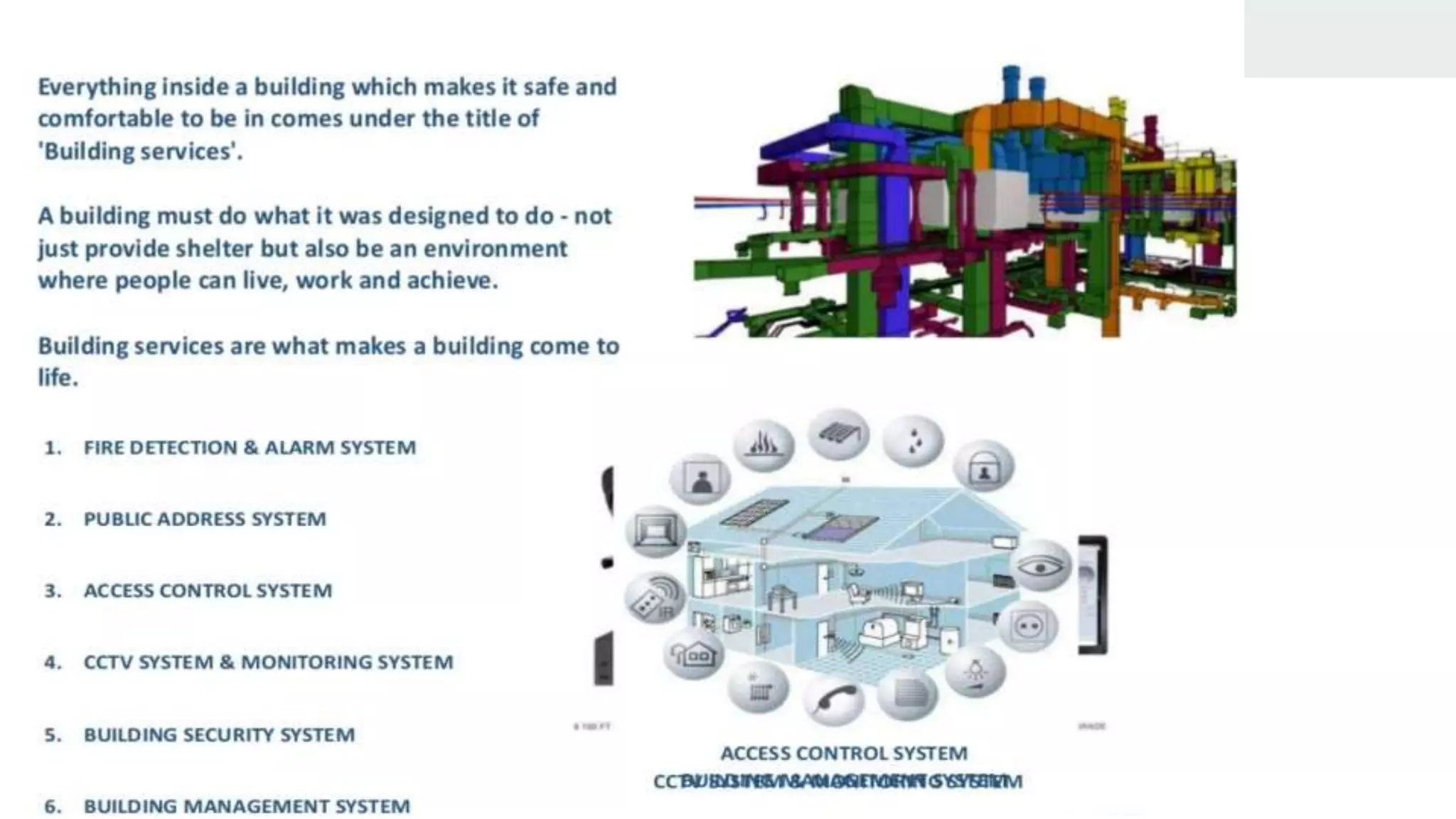

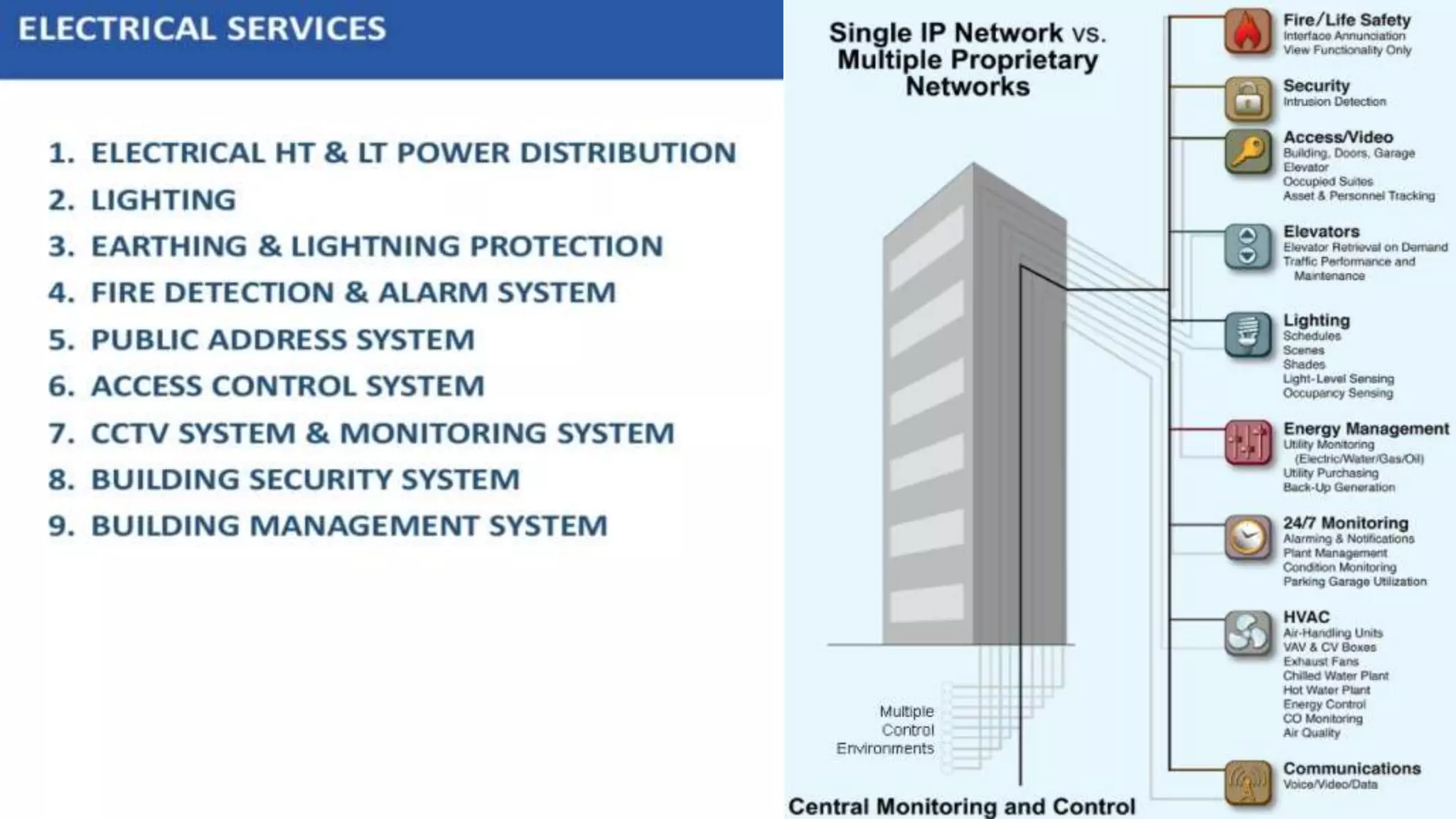

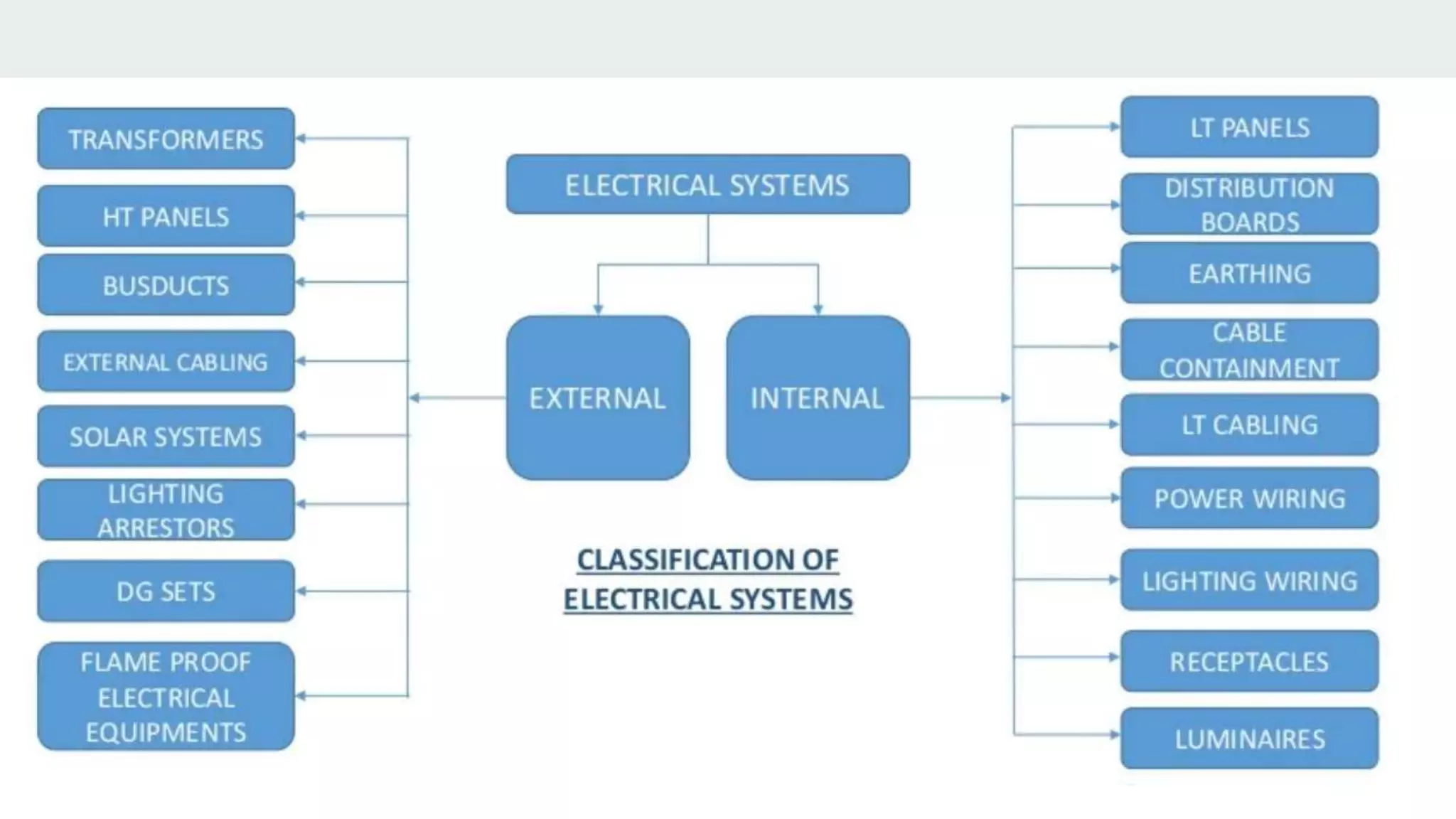

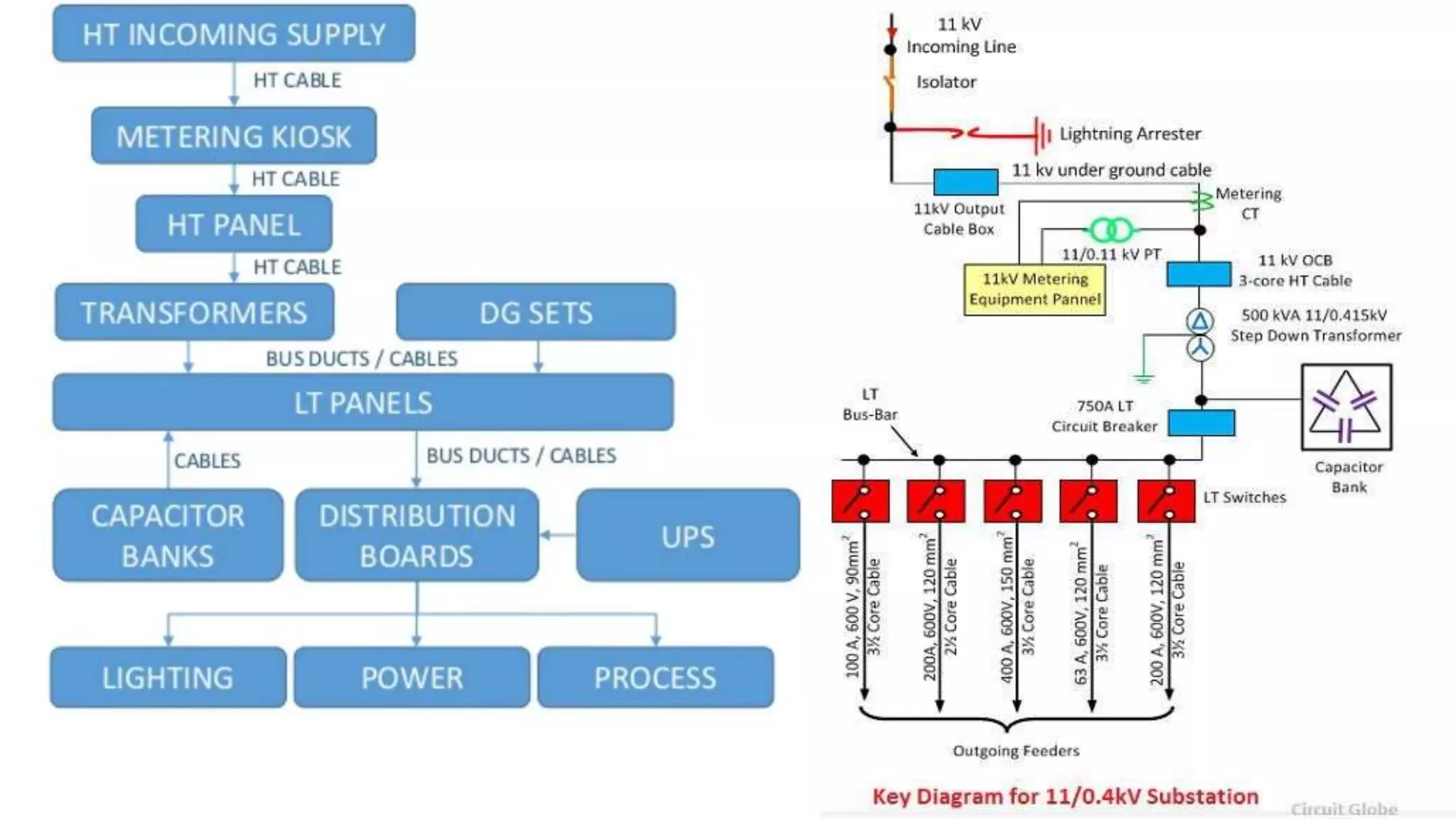

MEP stands for mechanical, electrical, and plumbing systems that are essential for the comfort, functionality, and safety of buildings. These systems include various components such as HVAC, plumbing utilities, fire safety systems, and energy-efficient technologies like variable refrigerant flow systems. The document discusses MEP system requirements and advanced technologies to enhance building performance throughout the construction and operational phases.