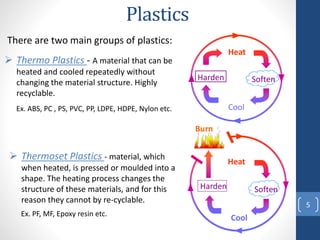

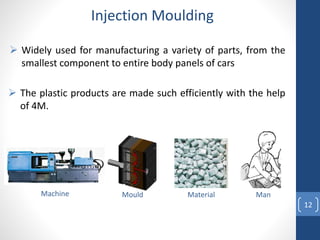

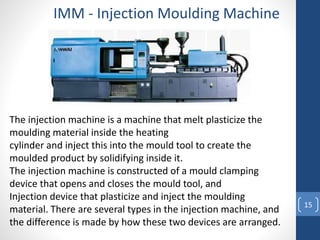

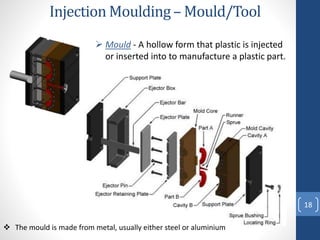

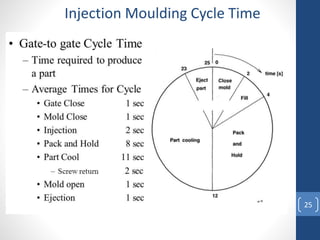

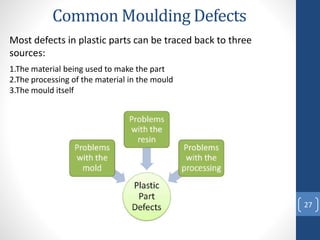

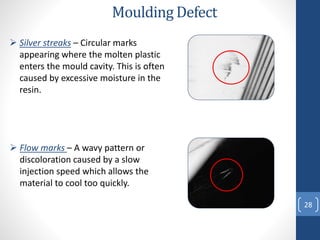

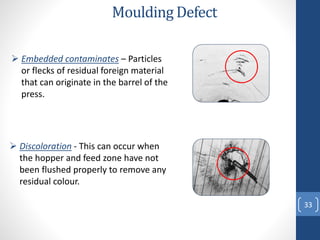

The document provides information about plastic injection moulding. It defines plastic as a polymeric substance that can be easily shaped and moulded. Plastics are used for their ability to be formed into complex shapes, their light weight, strength and availability in different colors. The main types of plastics are thermoset and thermoplastic. Injection moulding is described as the process of injecting melted plastic into a mould to form a part. Key aspects of the injection moulding process like the machine, mould, raw materials and defects are discussed. Injection moulding is concluded to be a very versatile process for producing a wide variety of plastic products.