This document provides information about walnut production, including:

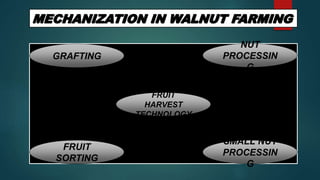

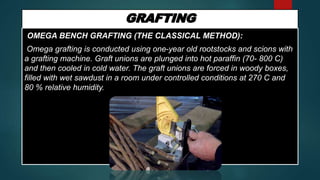

- Omega grafting is the classical grafting method used to propagate walnut trees, involving grafting scions onto rootstocks with a grafting machine.

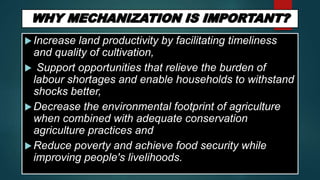

- Mechanization of agriculture can increase land productivity, support households facing labor shortages, reduce environmental impacts, and help reduce poverty and ensure food security.

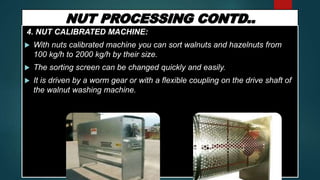

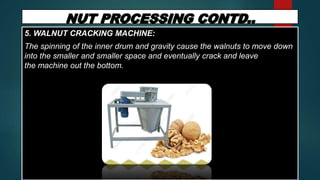

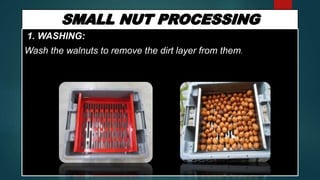

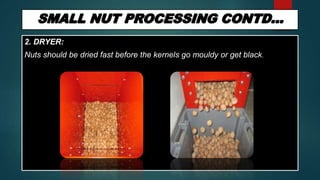

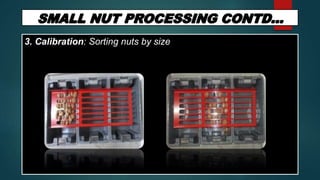

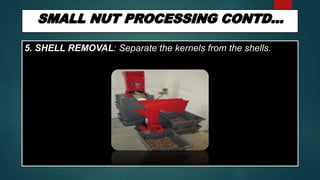

- Walnut harvesting and processing involves several steps: shaking or harvesting fruits from trees; sorting; drying; calibrating by size; cracking shells; and removing shells to obtain the kernels. Specialized machinery is used for each processing step.