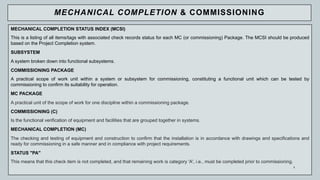

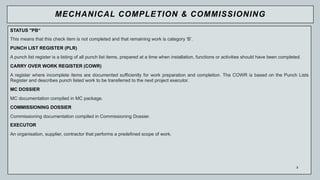

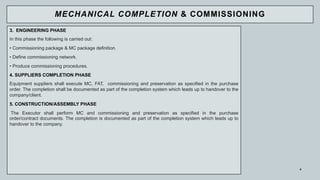

The document defines mechanical completion and commissioning. Mechanical completion involves checking equipment is installed correctly and ready for commissioning. Commissioning verifies systems function as intended. Key activities for mechanical completion include inspections, testing, and documentation. Commissioning activities include system testing, instrumentation calibration, and verifying equipment and systems meet objectives. The document provides details on planning, executing, and documenting mechanical completion and commissioning.