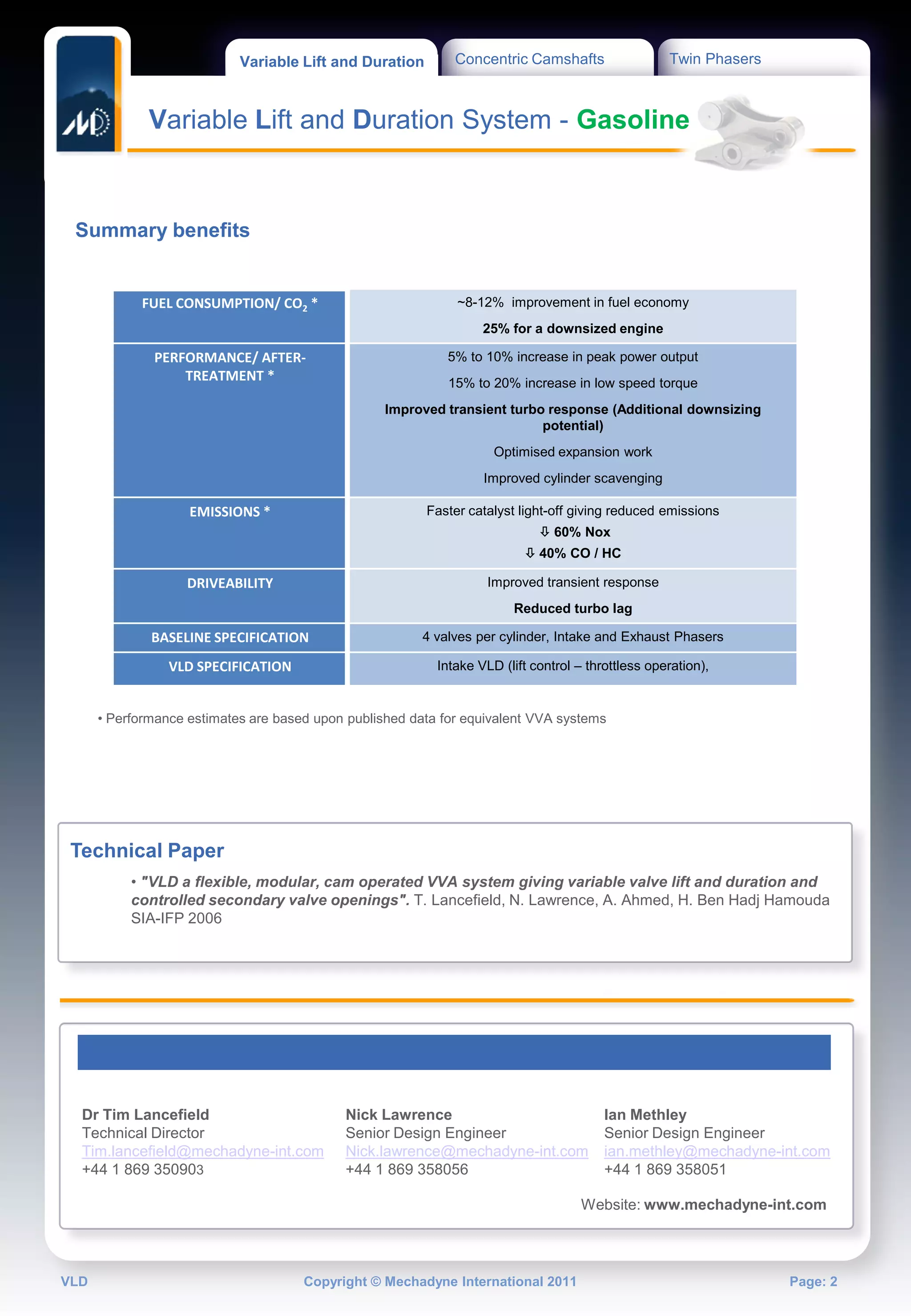

The document describes a Variable Lift and Duration (VLD) system, which is a fully variable mechanical valvetrain capable of controlling valve lift and duration. It can provide up to an 8-12% improvement in fuel economy and a 5-10% increase in peak power output. The VLD system uses two cam profiles to produce a single valve lift profile and allows control of valve lift, duration, and additional valve lift events. It has reached mature development with over 1000 hours of prototype engine running.