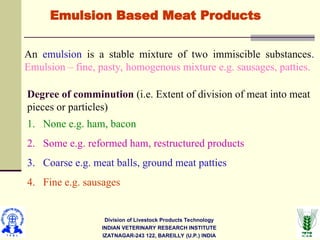

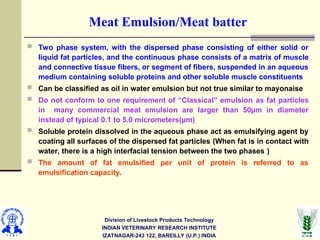

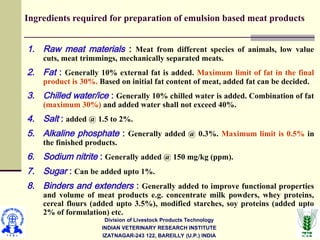

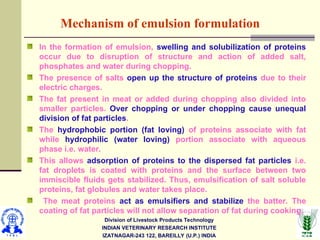

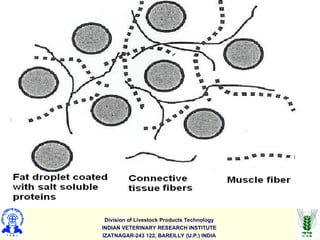

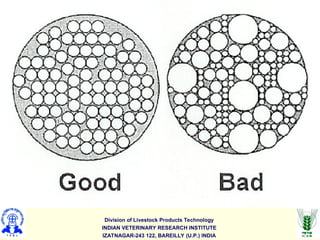

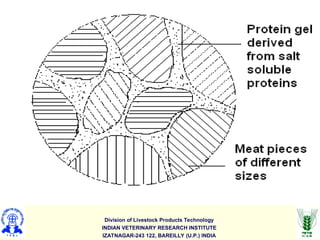

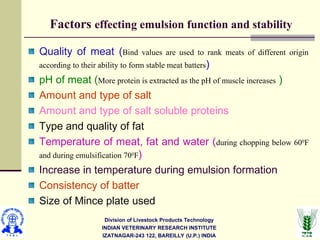

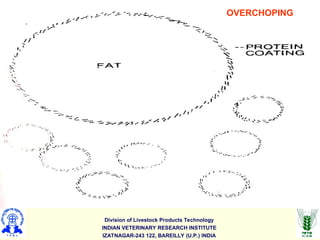

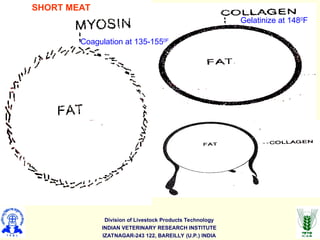

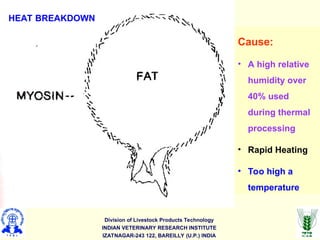

The document discusses the preparation of meat emulsions, which are stable mixtures vital for creating various meat products like sausages and patties. Key factors affecting emulsion stability include meat quality, pH levels, salt type, and temperature during processing. Ingredients such as raw meat, fat, salt, and binders are essential, and proper technique in processing ensures product quality and reduces moisture and fat loss during cooking.