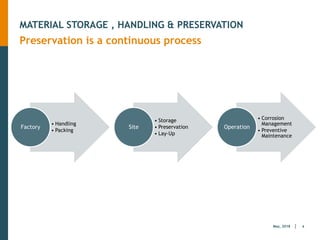

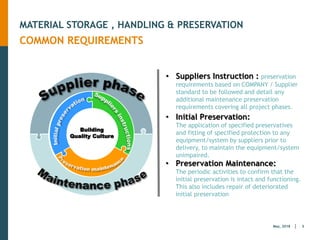

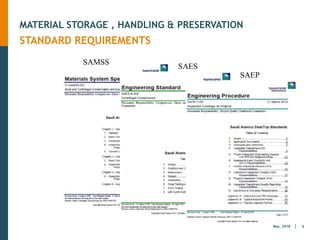

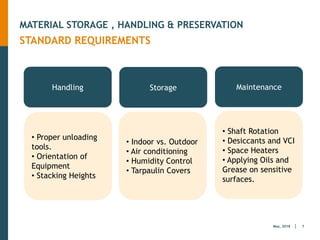

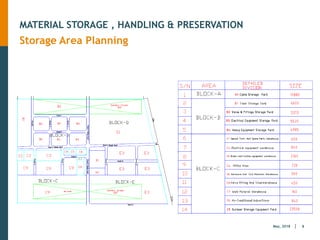

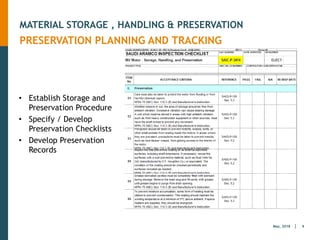

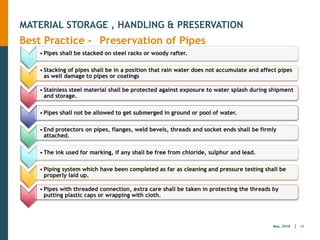

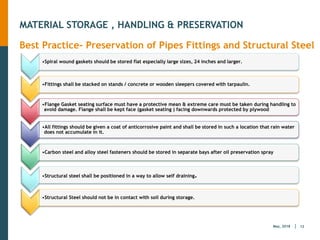

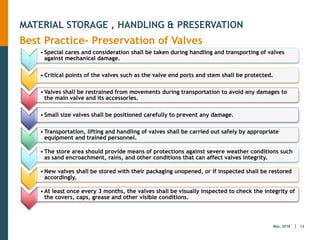

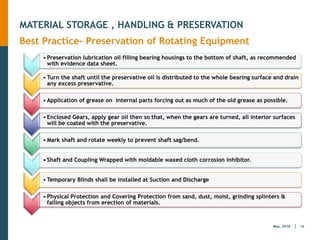

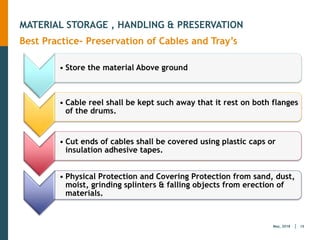

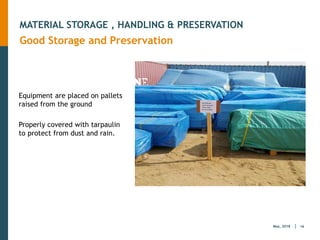

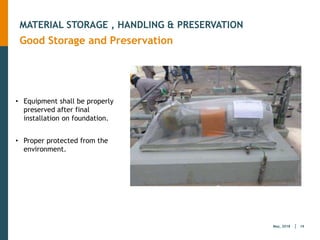

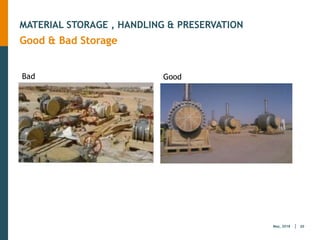

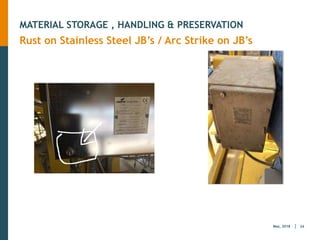

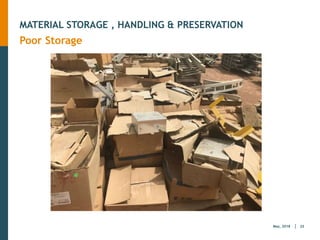

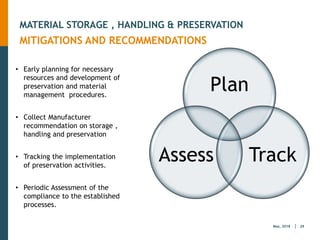

This document discusses best practices for material storage, handling, and preservation. It covers the importance of preservation, common requirements, planning and tracking preservation activities, lessons learned, and recommendations. The key points are proper handling and storage, applying preservatives, periodic inspections, tracking preservation records, and assessing compliance to preservation procedures. The document provides best practices for preserving different equipment and materials.