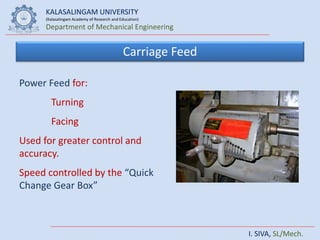

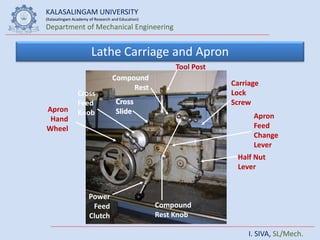

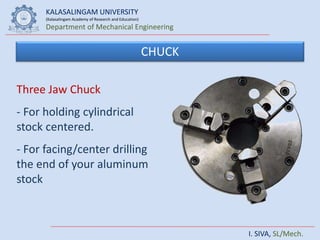

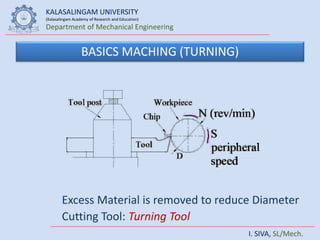

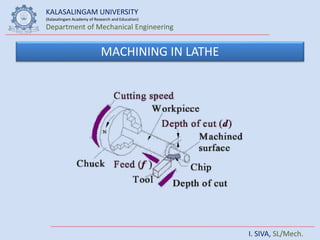

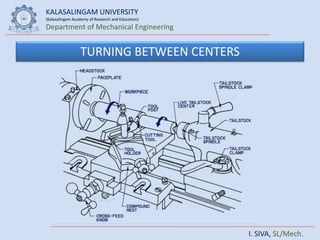

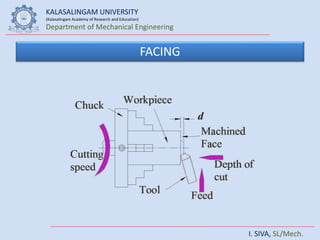

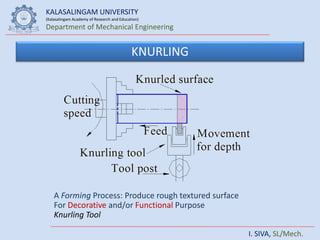

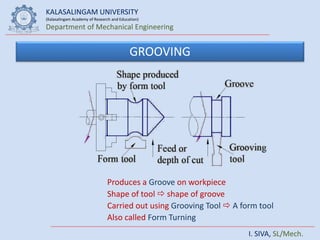

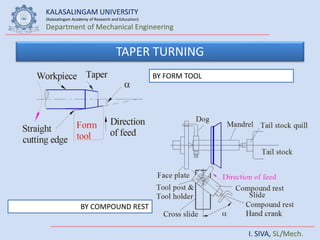

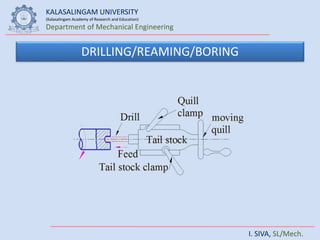

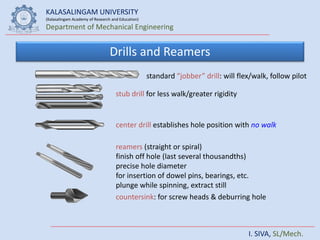

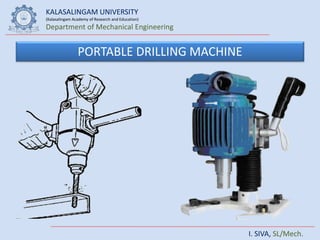

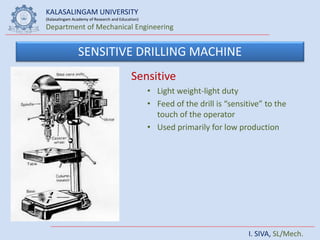

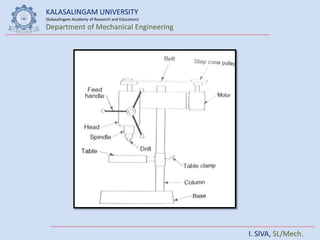

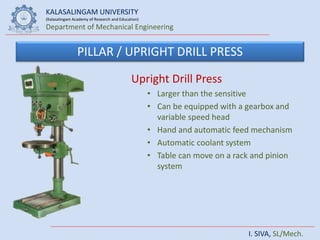

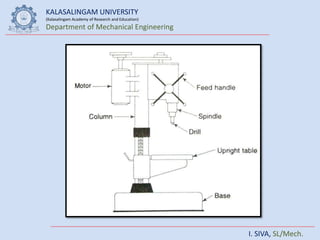

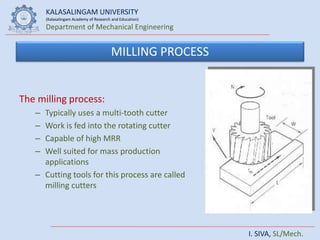

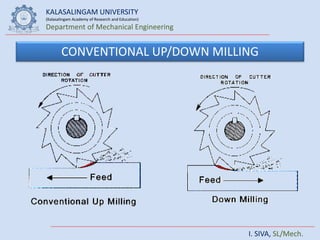

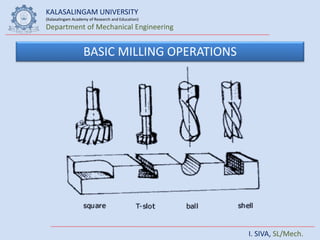

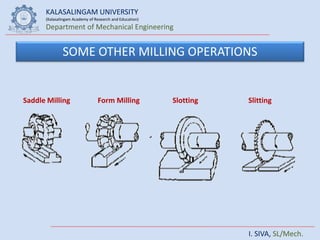

The document discusses various machining processes used in manufacturing. It describes lathe operations like turning, facing, knurling and tapering. It also discusses drilling operations using different types of drilling machines like sensitive drilling machine, pillar drilling machine, radial drilling machine and gang drilling machine. Milling operations like conventional up/down milling and other operations like saddle milling and form milling are also summarized.