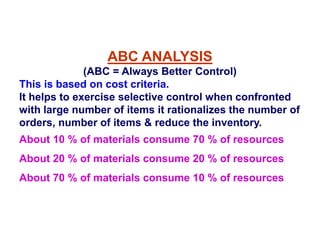

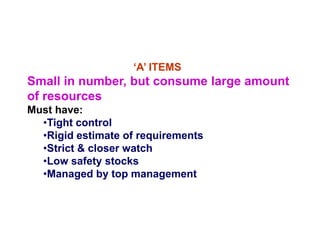

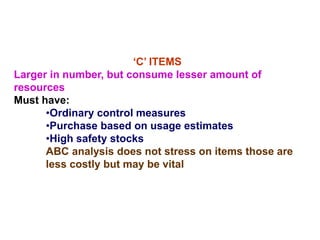

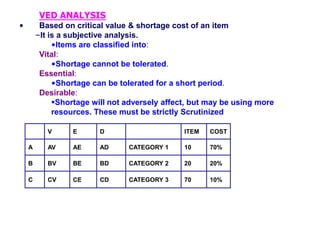

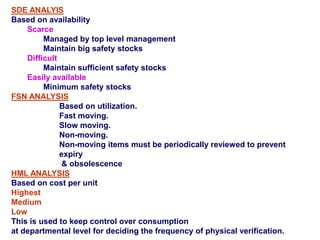

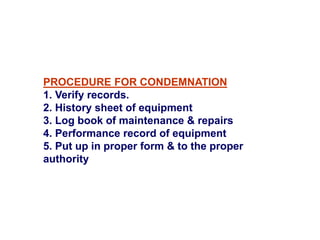

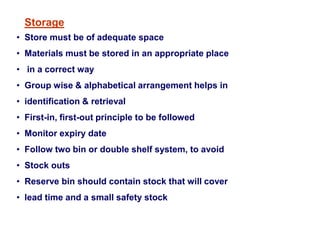

Material management involves planning, organizing, and controlling the flow of materials from purchase to distribution. Its aims are to obtain the right quality and quantity of supplies at the right time, place, and cost. Key objectives include obtaining the lowest prices, minimizing inventory levels, and operating efficiently. Effective material management requires classifying items using various analyses to determine appropriate inventory controls and safety stock levels based on factors like cost, criticality, usage, and availability. Proper storage, ordering, and disposal procedures help ensure an organization has needed materials while minimizing costs and waste.

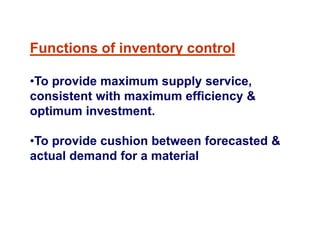

![Economic order of quantity

EOQ = Average Monthly Consumption X Lead Time [in

months] + Buffer Stock – Stock on hand

CARRYING

COST

PURCHASING

COST

ECONOMIC ORDER OF

QUANTITY(EOQ)](https://image.slidesharecdn.com/materialmanagemetppt-200410175258/85/Material-managemet-ppt-9-320.jpg)