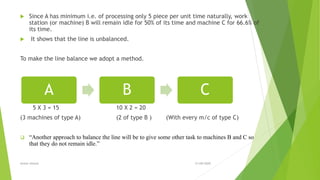

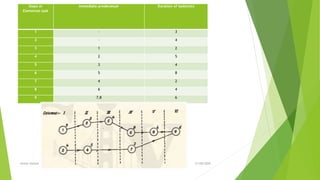

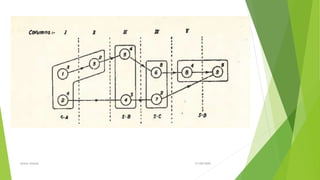

The document discusses assembly line balancing and material handling. It covers the concept of assembly line balancing, including how to distribute tasks evenly across workstations to minimize idle time. It also covers the concept of material handling, the functions and principles of material handling including minimizing movement and using appropriate equipment. Finally, it discusses different types of material handling equipment and factors to consider when selecting equipment.