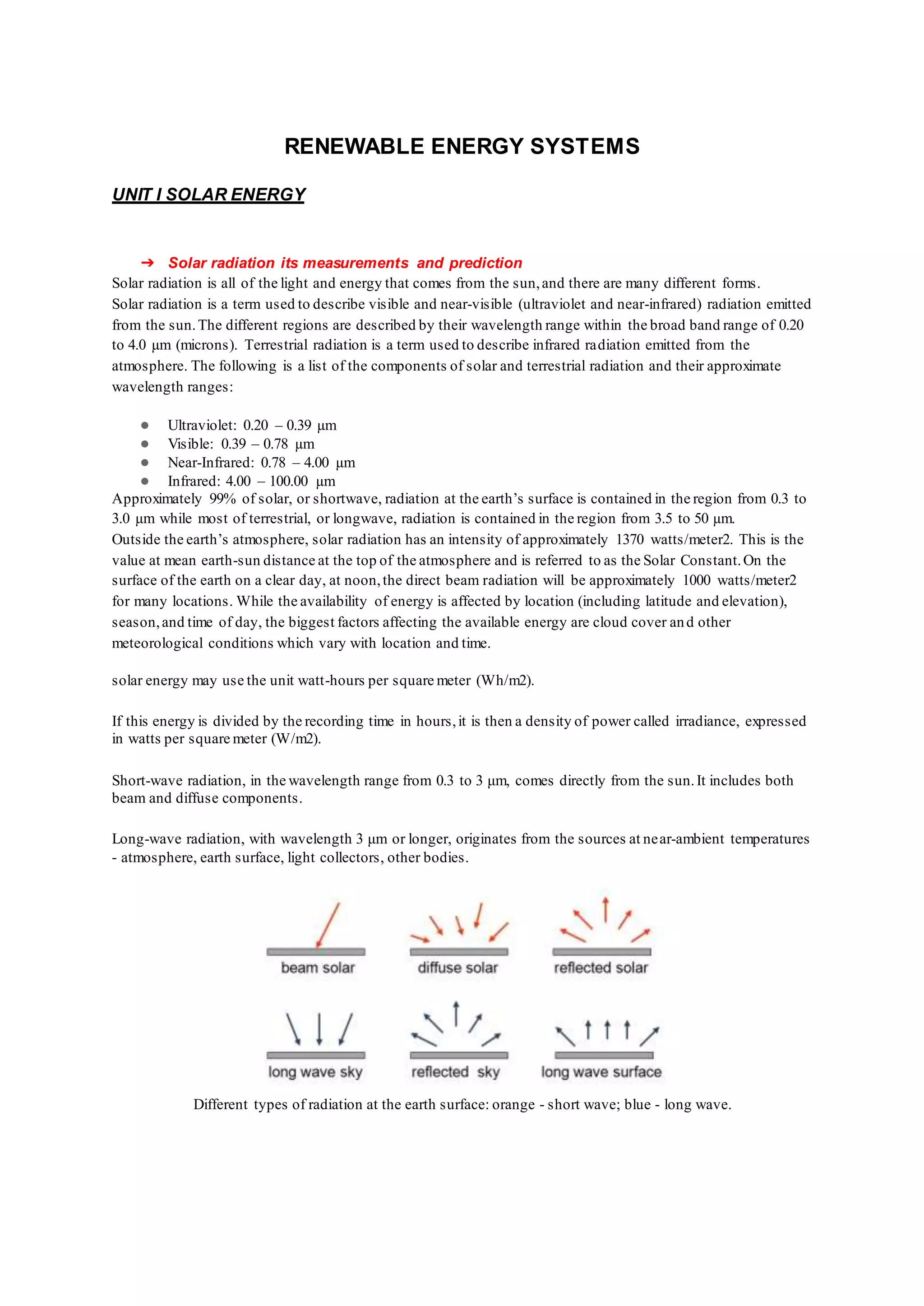

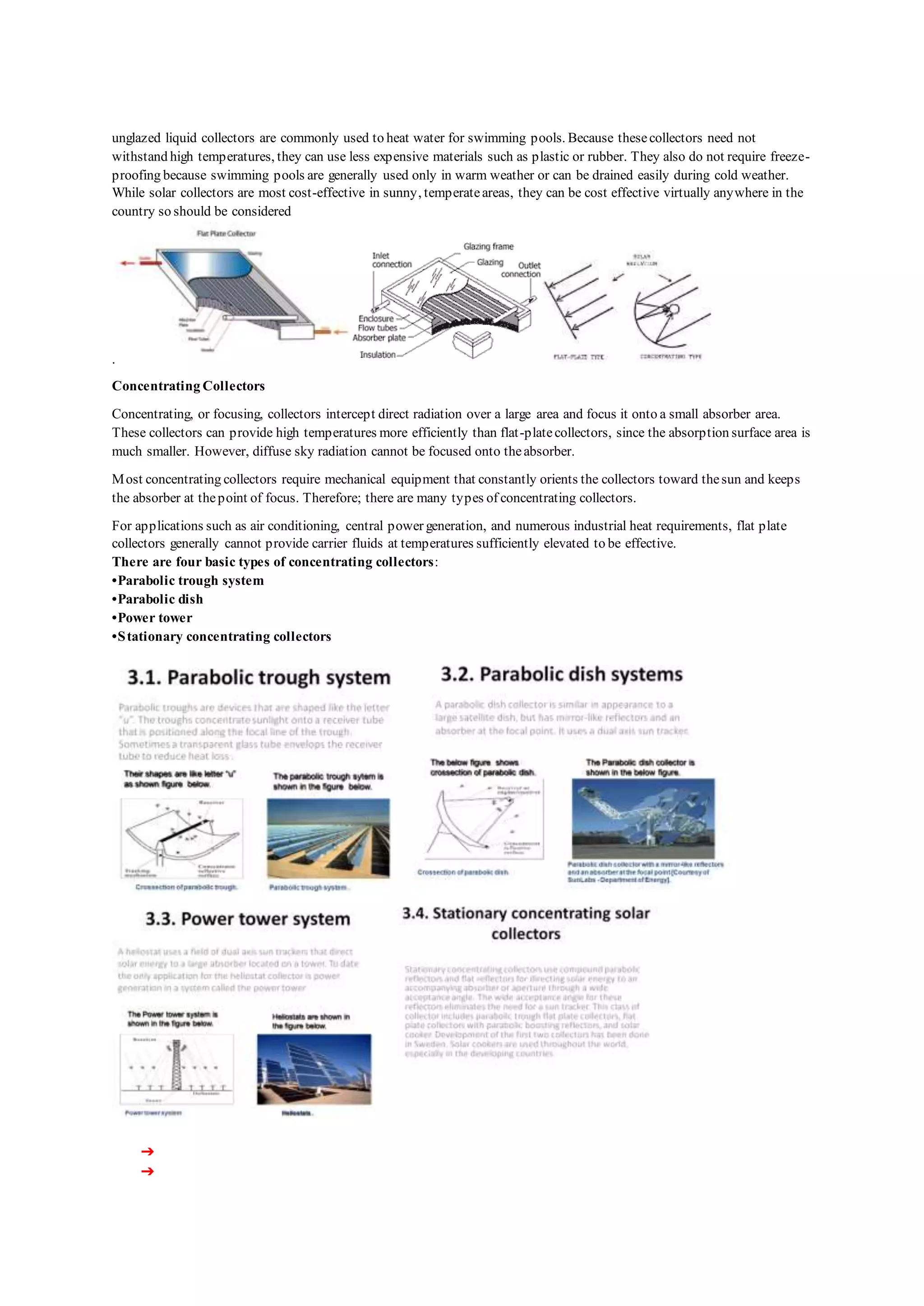

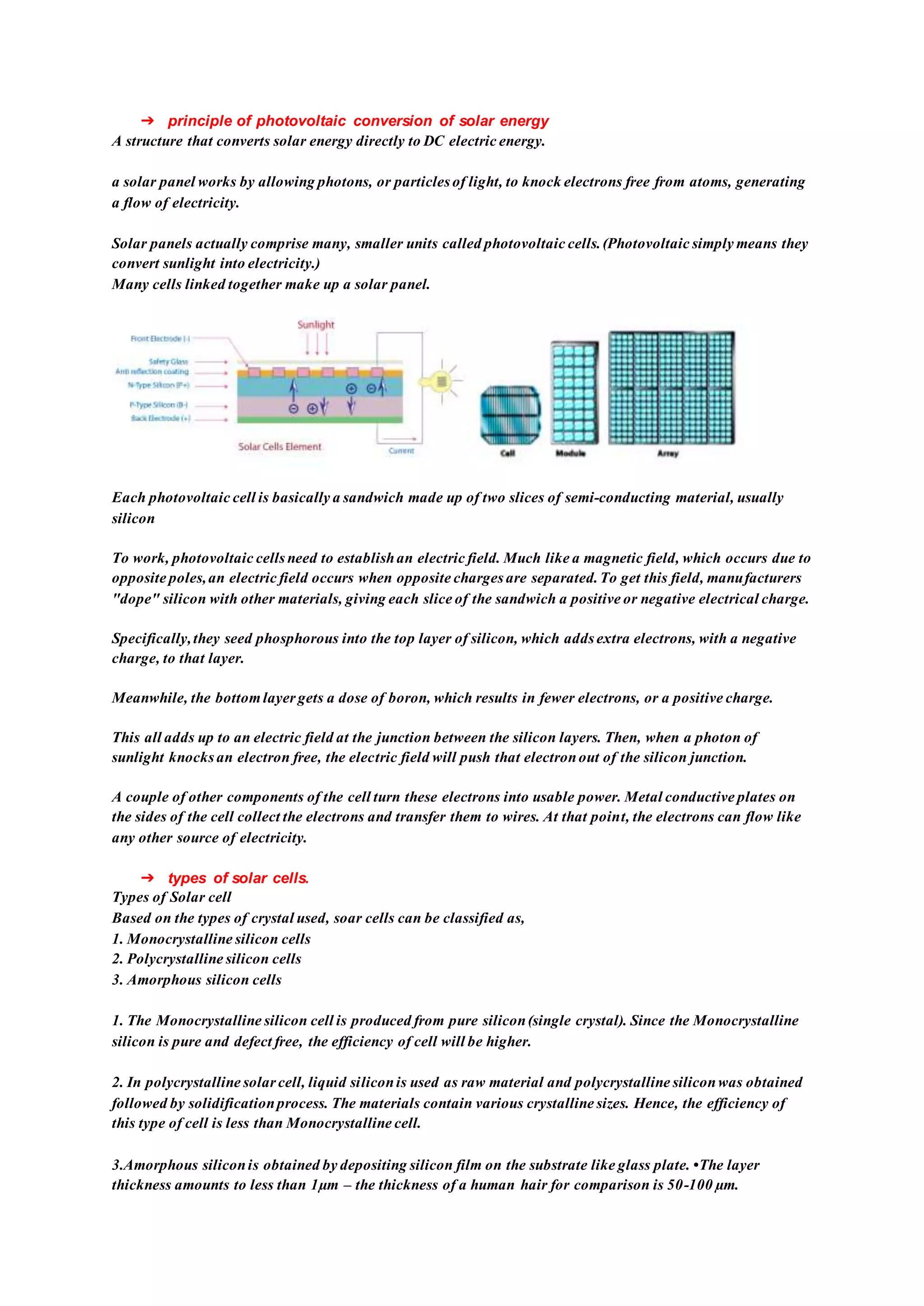

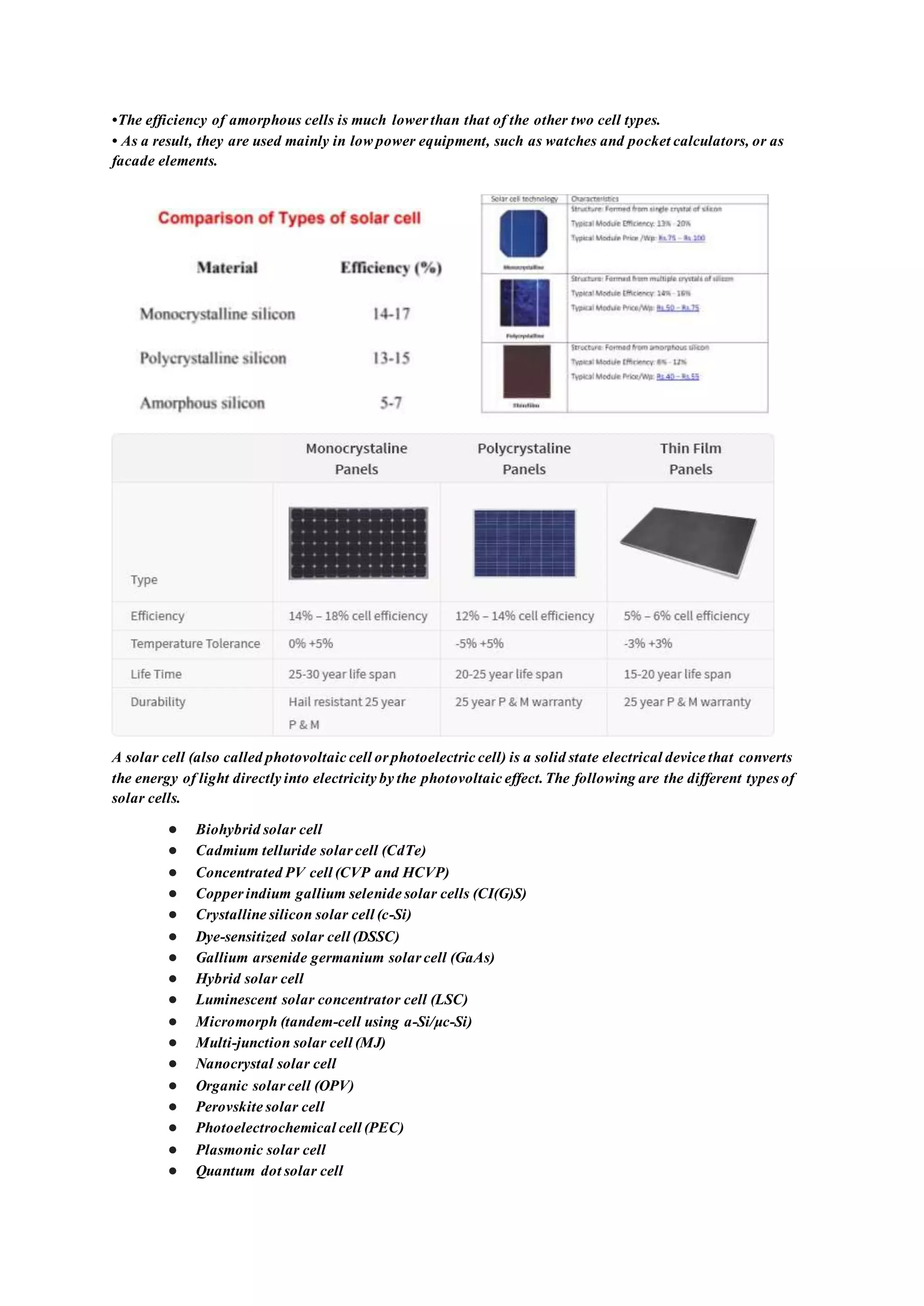

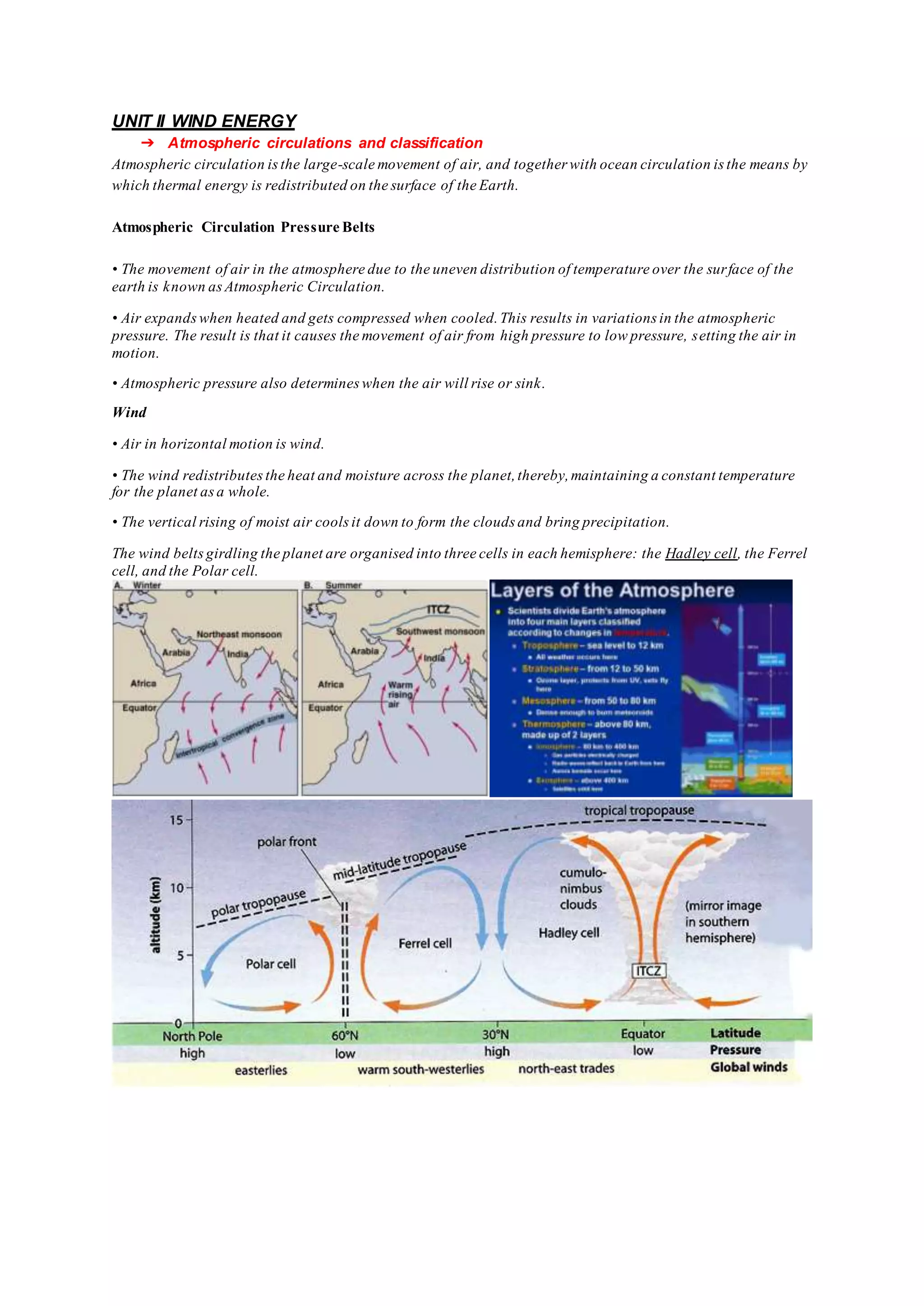

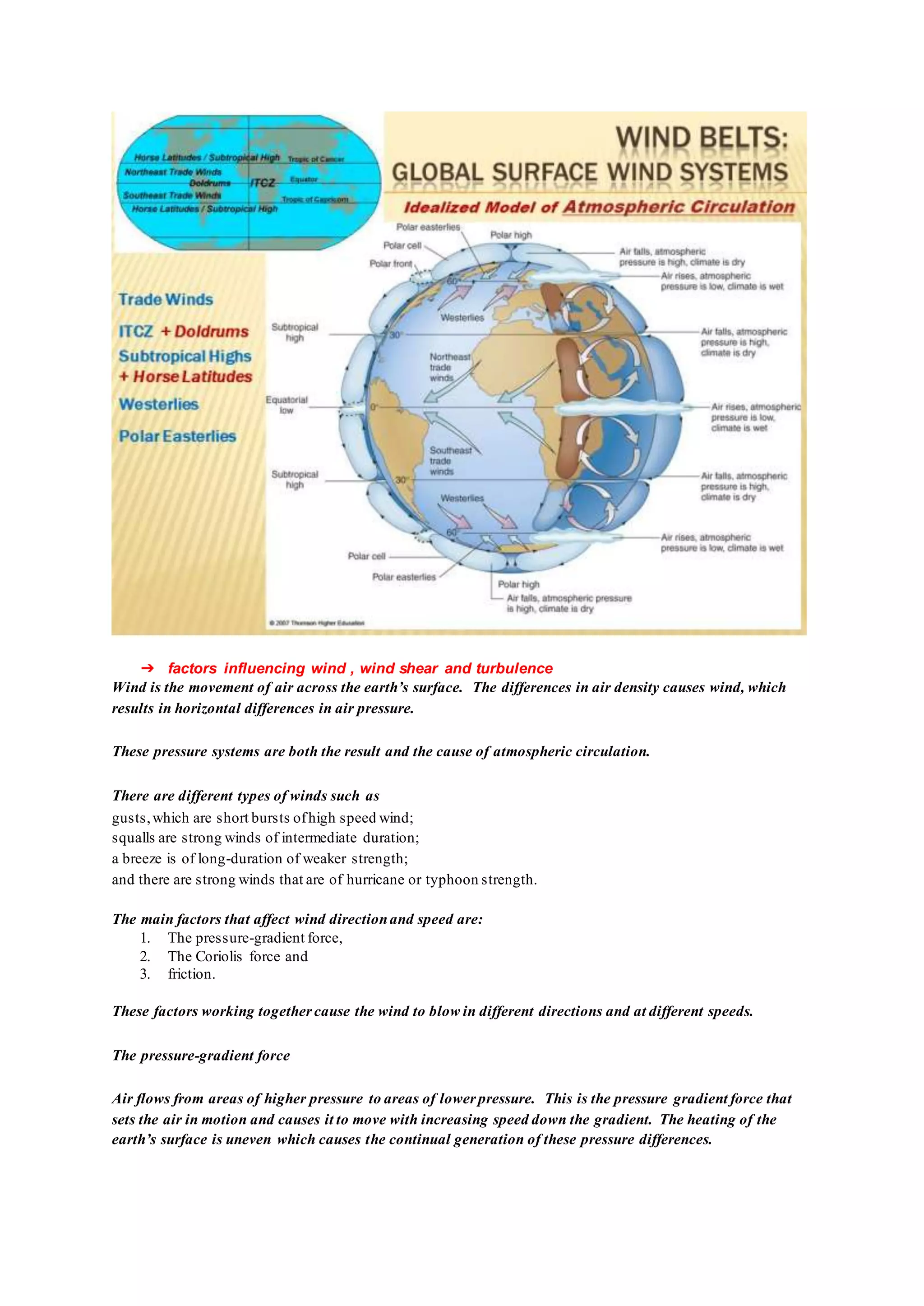

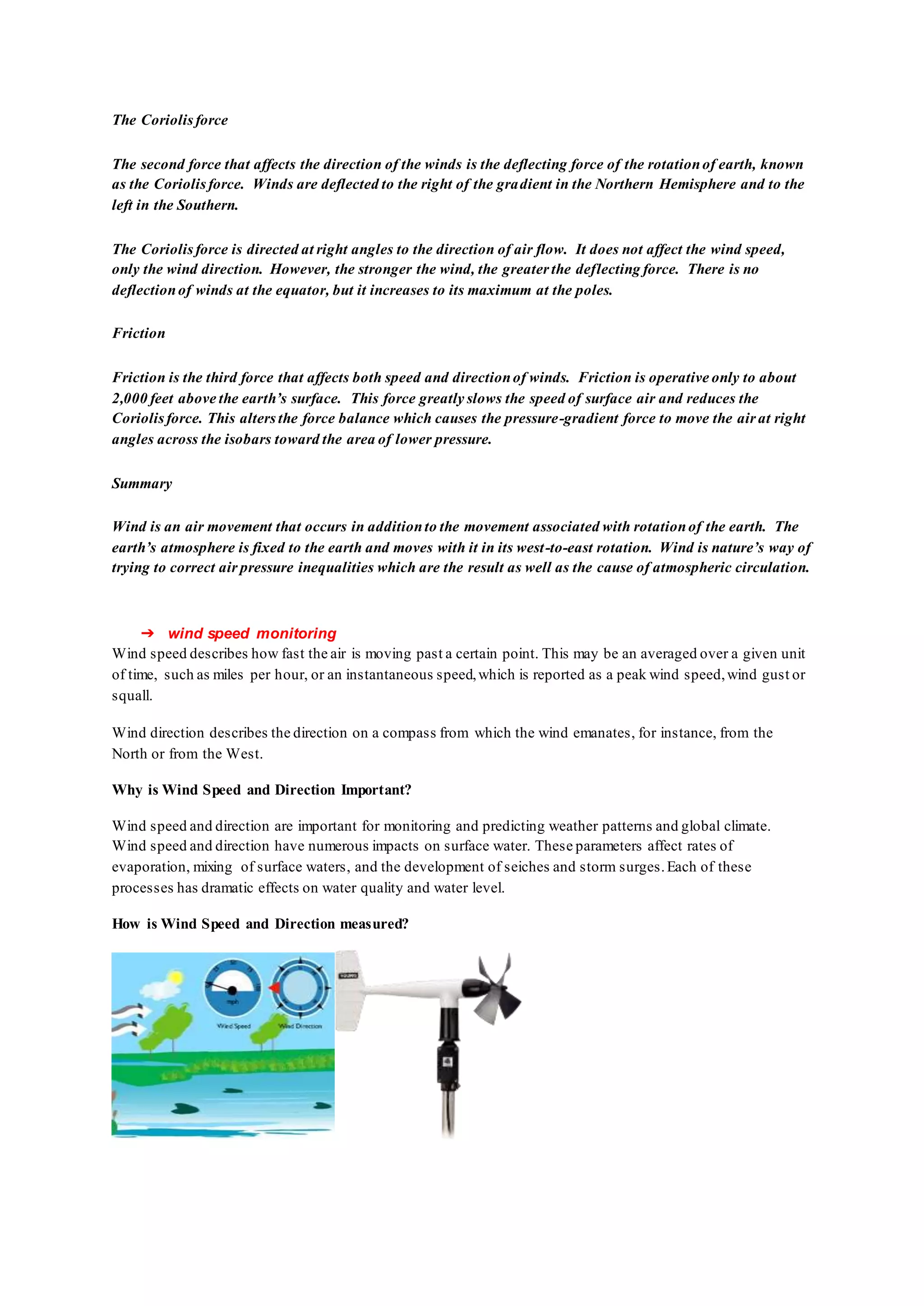

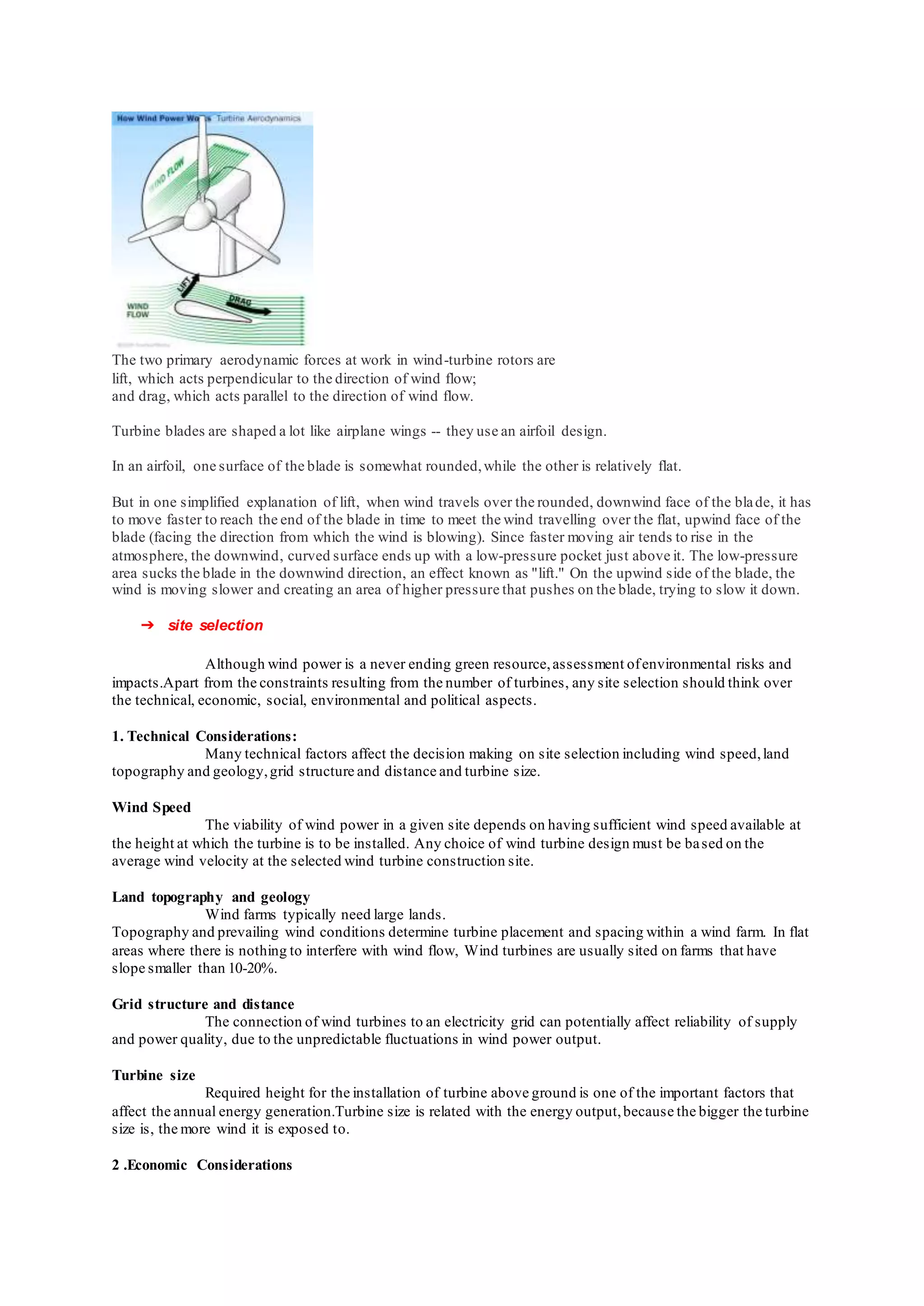

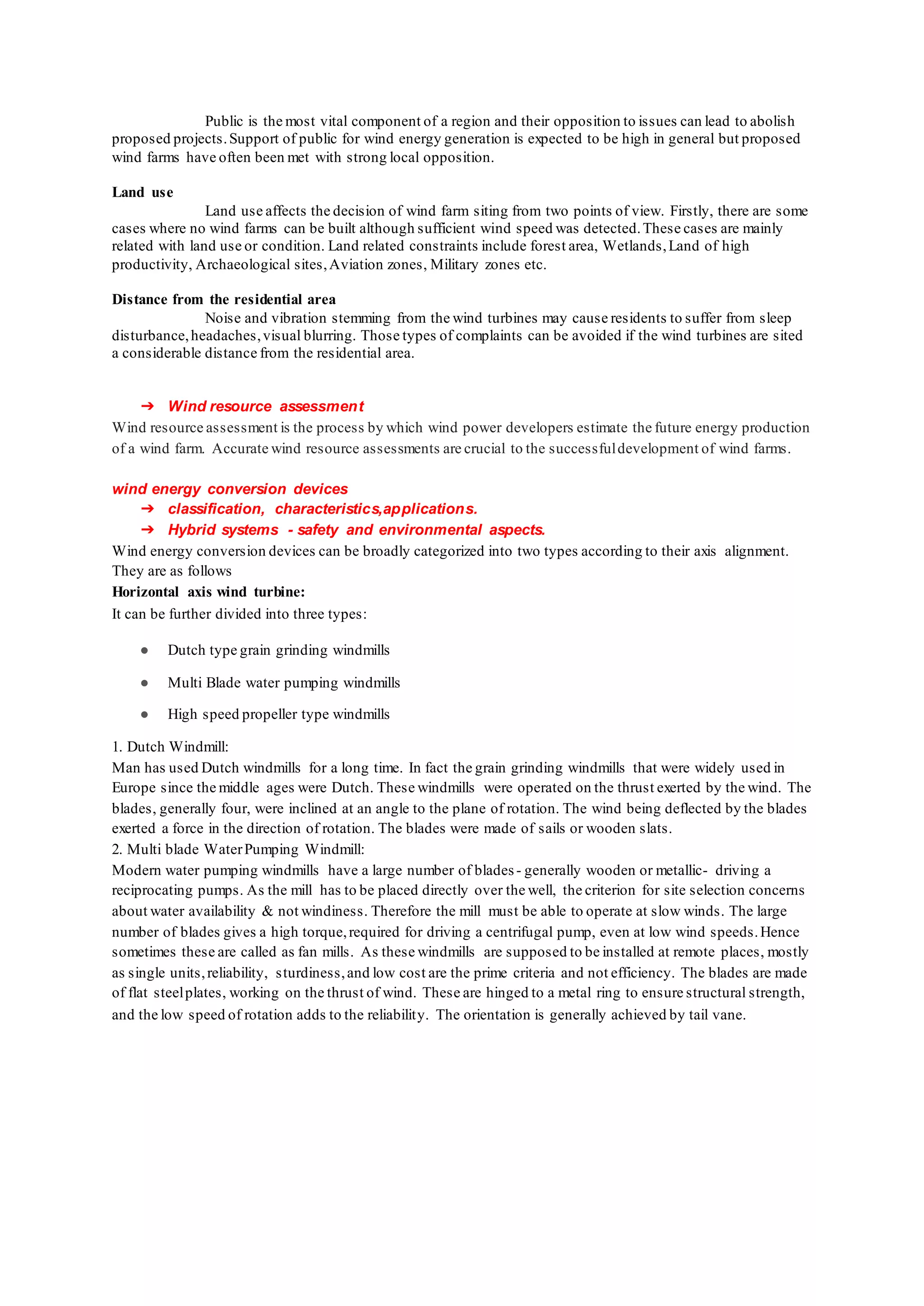

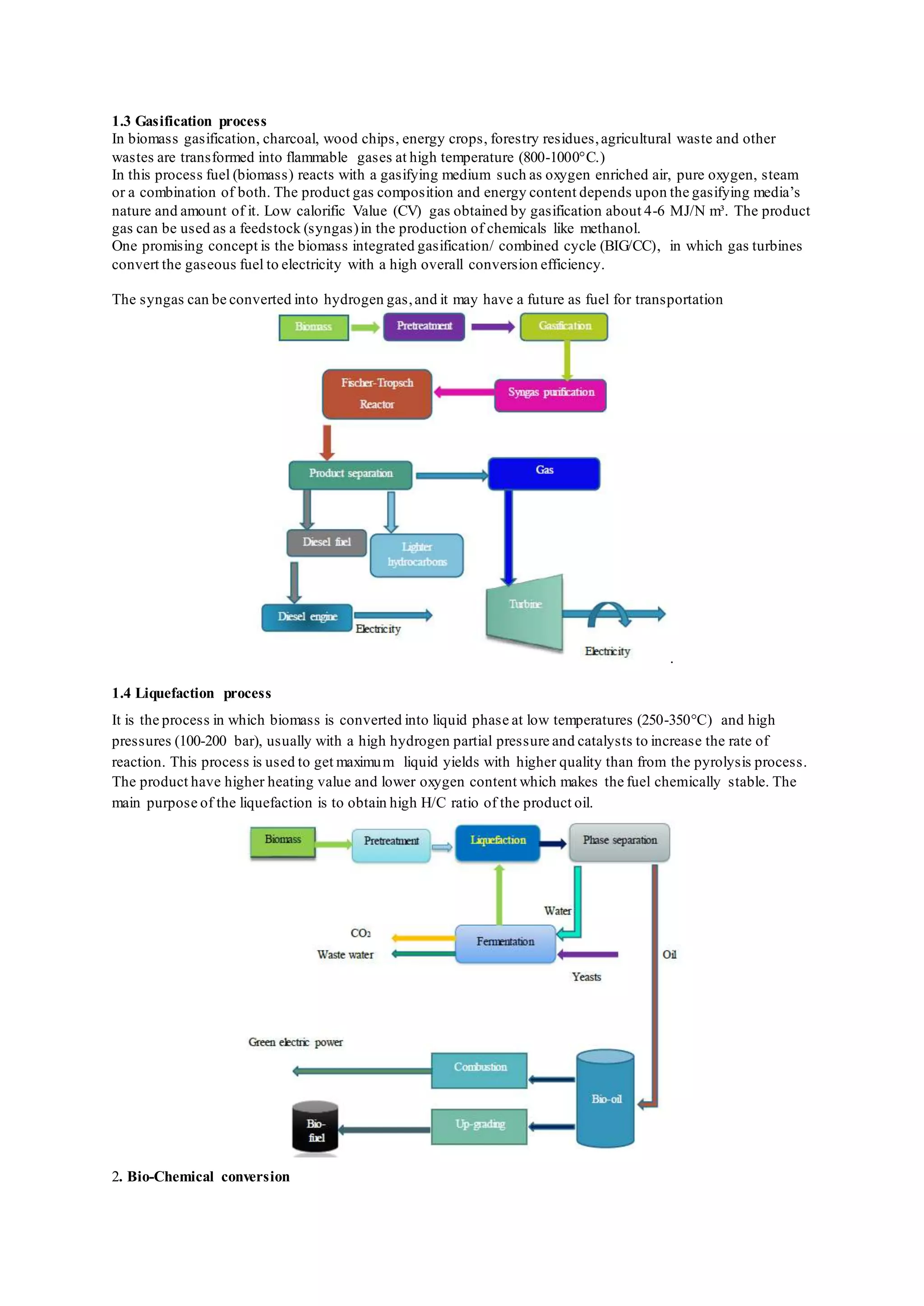

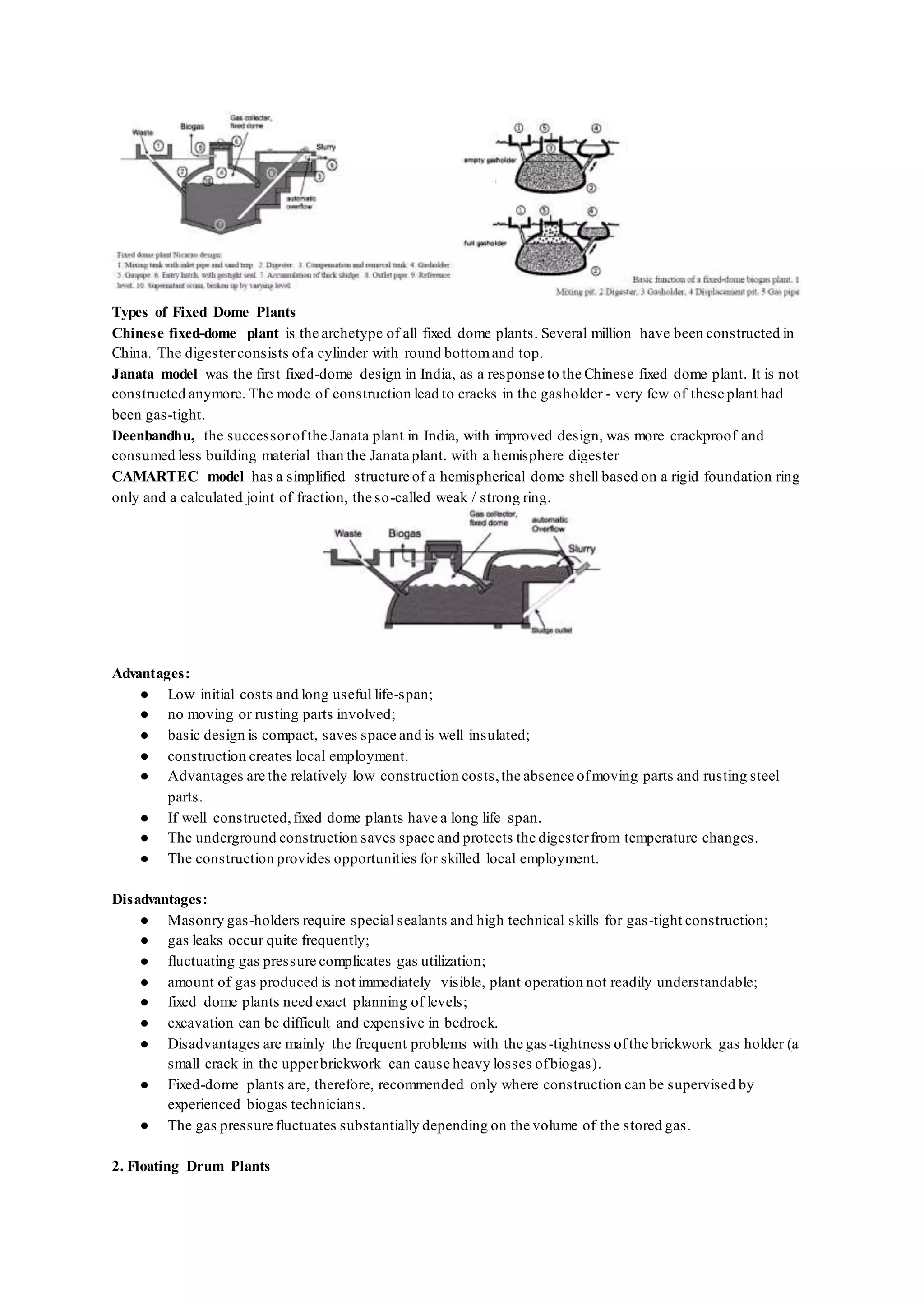

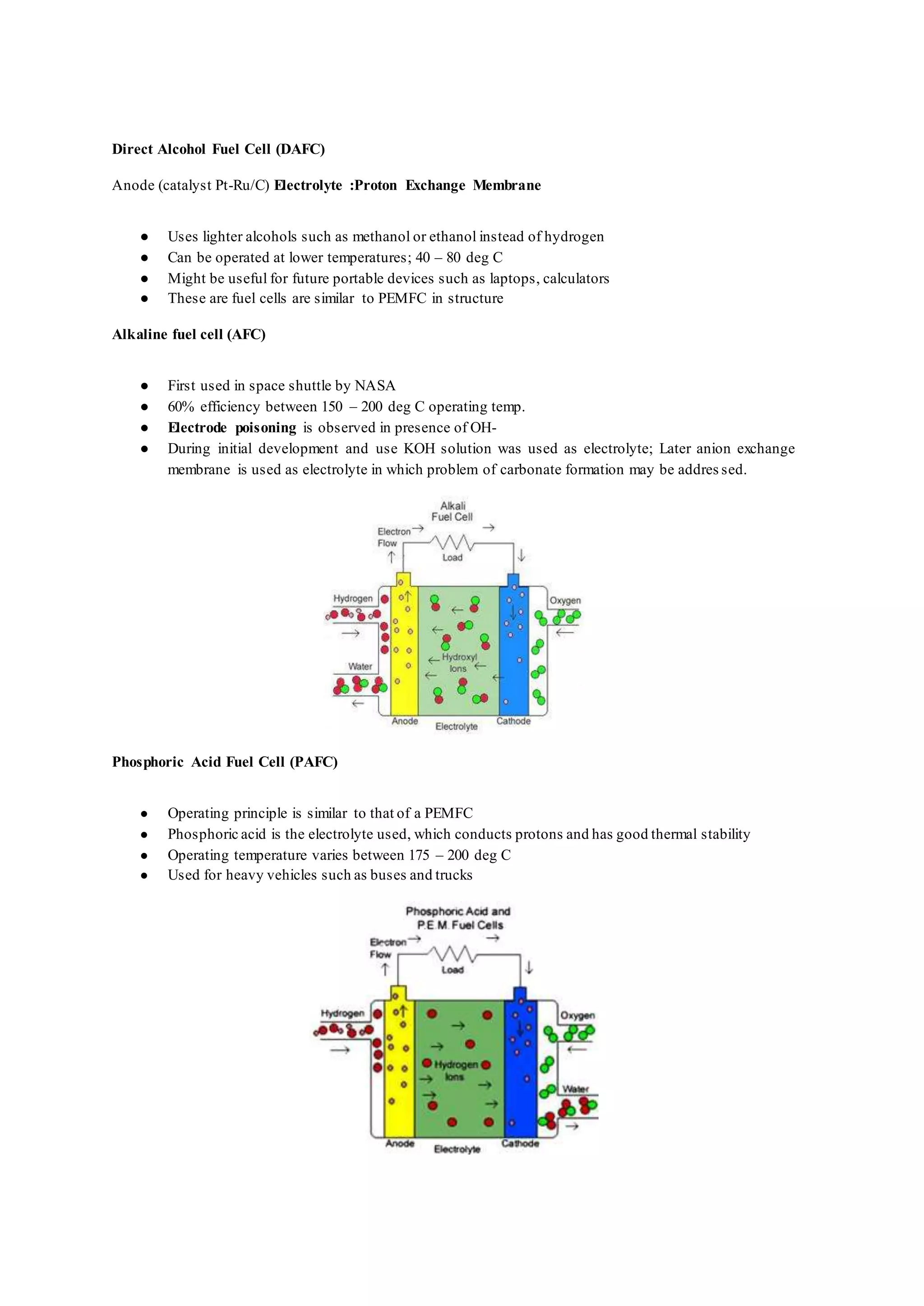

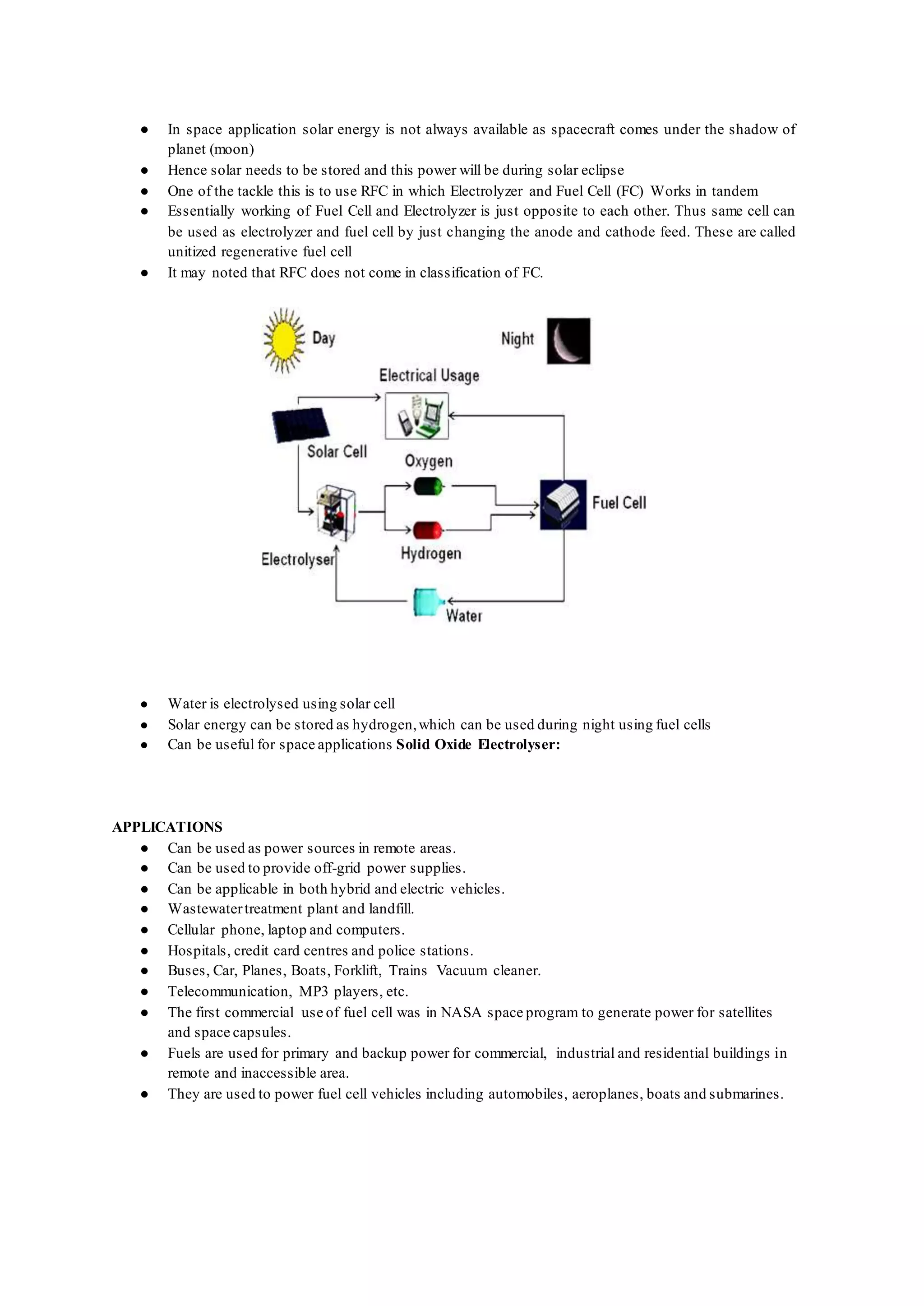

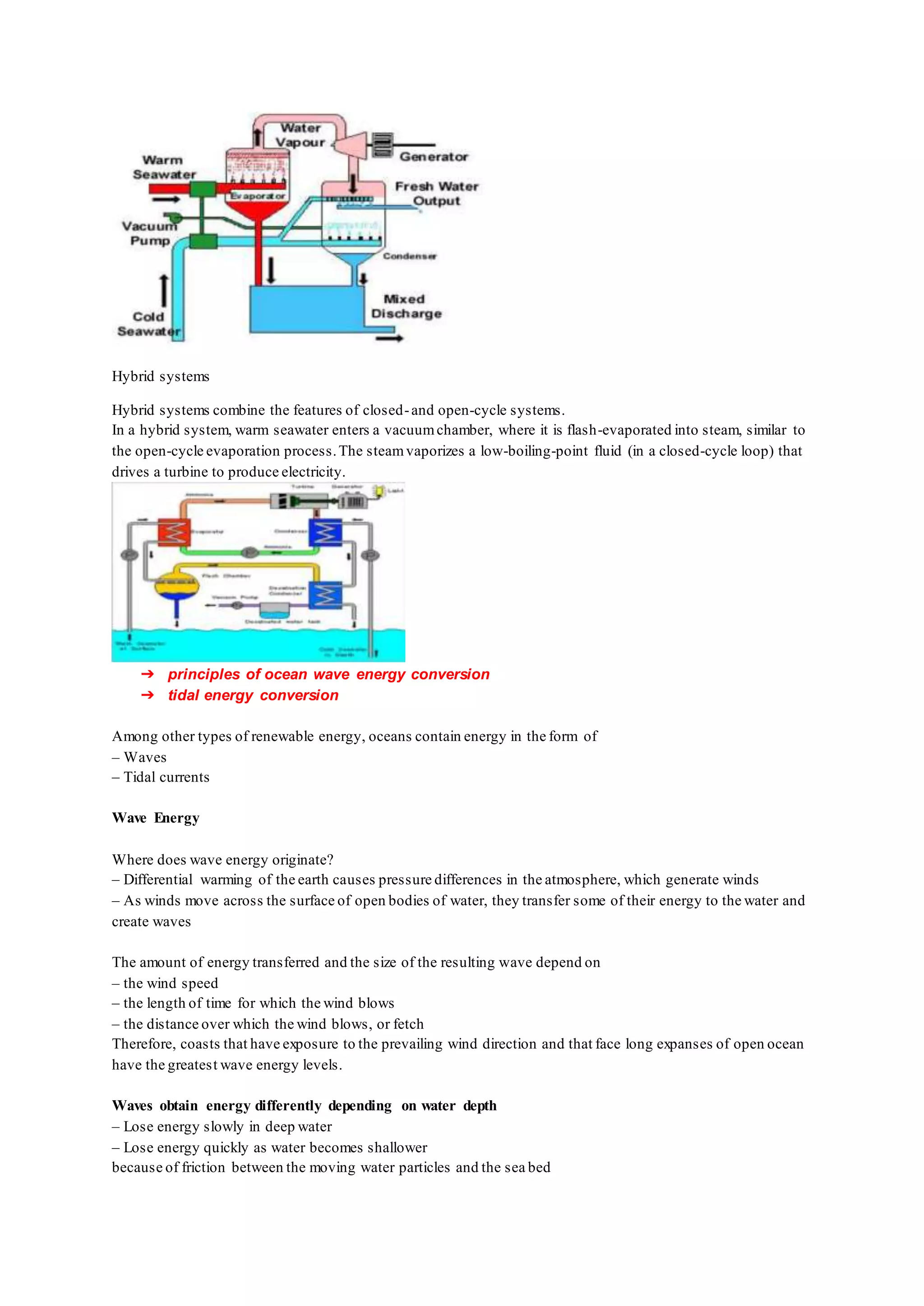

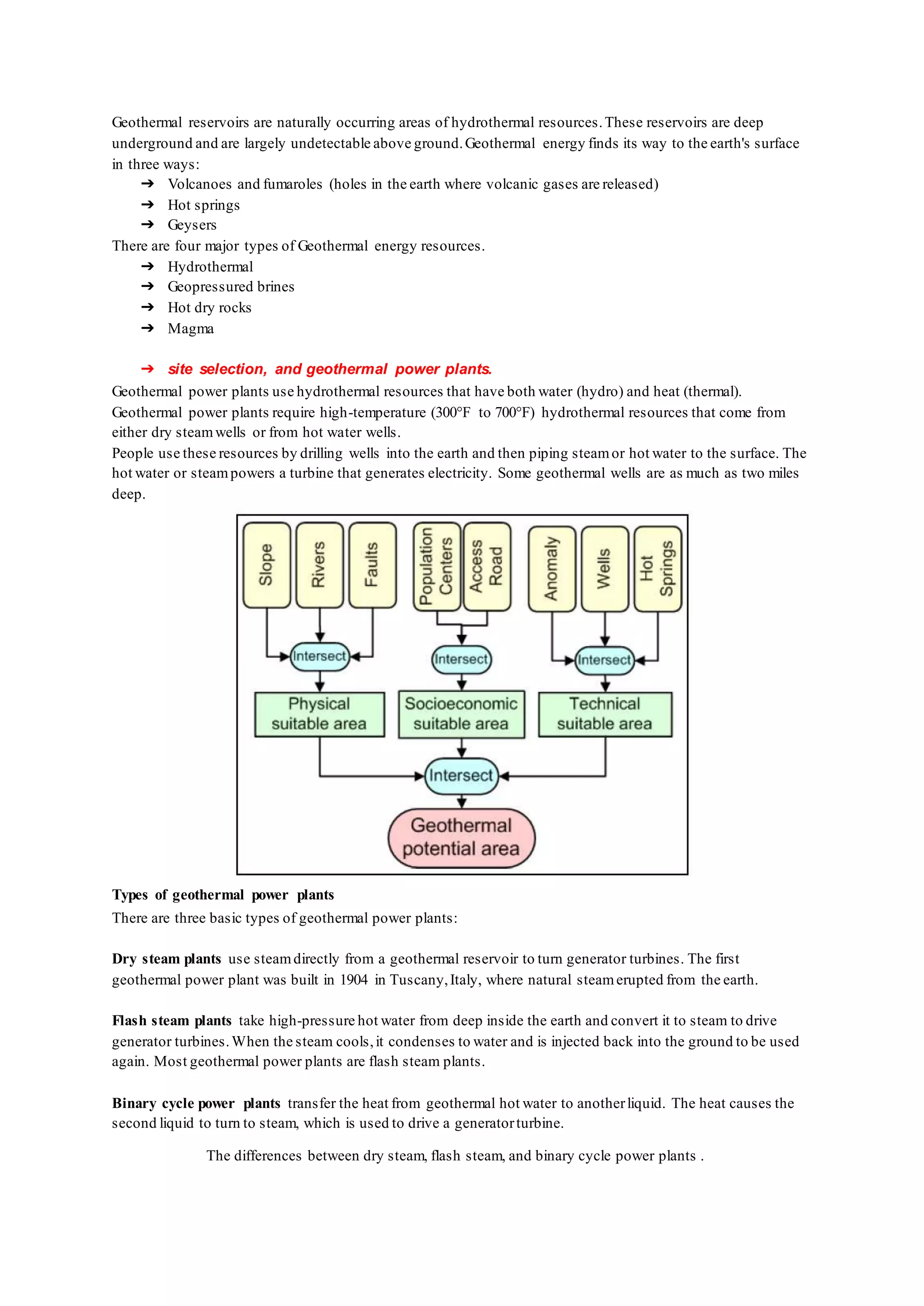

This document provides an overview of renewable energy systems, focusing on solar, wind, bio-energy, hydrogen, and other alternative energy sources. It details the principles, applications, and environmental economics of various renewable energy technologies, highlighting their benefits compared to fossil fuels. Each energy source is examined in terms of its mechanisms, components, and practical uses in residential and industrial contexts.