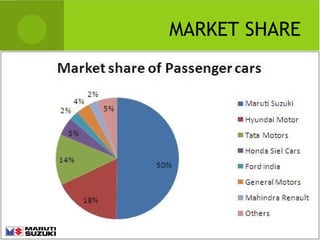

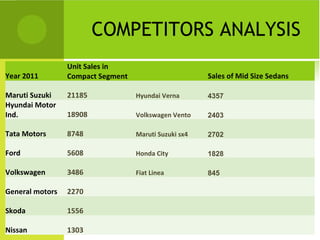

Maruti Suzuki was established in 1981 and began production in 1983. It is now called Maruti Suzuki India Ltd and is headquartered in New Delhi. 54.2% of its shares are owned by Suzuki Motor Corporation of Japan. It has over 9,000 employees and manufactures its vehicles at plants in Gurgaon and Manesar, with a total annual production capacity of over 2 million vehicles. Maruti Suzuki dominates the Indian market, holding the top sales spots in both the compact segment and mid-size sedan segments in 2011.