Clay bricks are commonly used as building materials. The document discusses the materials, manufacturing process, and properties of clay bricks.

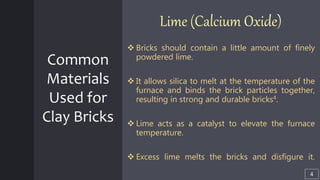

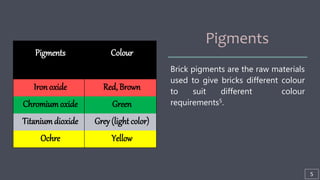

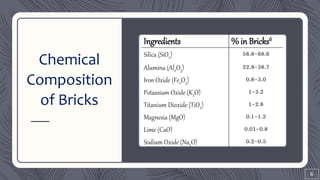

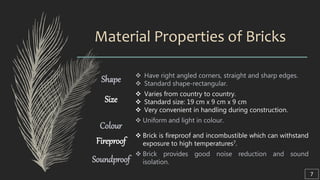

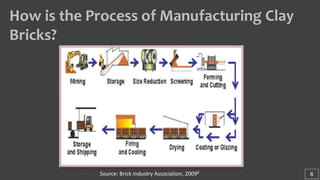

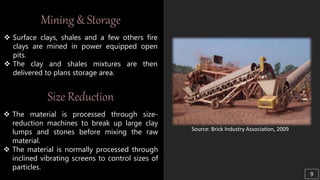

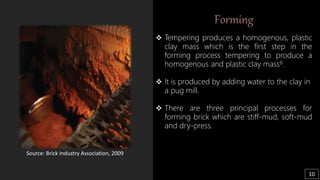

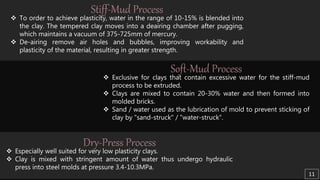

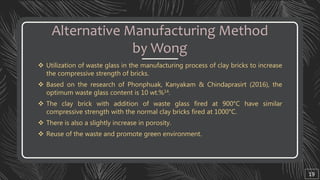

The key materials used are clay, sand, lime, and pigments. Clay provides plasticity while sand improves durability. Lime acts as a binder while pigments determine color. In manufacturing, raw materials are mined, crushed, formed into shapes, dried and fired in a kiln. Properties include resistance to fire and sound, as well as uniform shape and size. Alternative manufacturing methods discussed include additive manufacturing and use of natural fibers or waste materials.

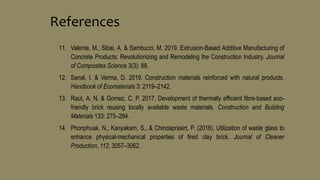

![References

1. Karaman, S., Gunal, H., & Ersahin, S. (2006). Assesment of clay bricks compressive strength using

quantitative values of colour components. Construction and Building Materials, 20(5), 348–354.

2. Khaled Jamal Abu Haweila & Ahmad Mostafa Hanhan. (2017). Lime – Enhanced properties of clay

bricks as a green building material.

3. Tahsina Alam. (2020). Composition of Bricks - Function of Ingredients. https://civiltoday.com/civil-

engineering-materials/brick/132-brick-composition-ingredients-with-functions. [17 July 2020]

4. Susmita B. (2020). Bricks: Composition, Qualities, Uses, Tests and Shape | Materials | Engineering

https://www.engineeringenotes.com/engineering-materials-2/bricks/bricks-composition-qualities-

uses-tests-and-shape-materials-engineering/46368 [13 July 2020]

5. Thomas Publishing Company. (2020). Types of Bricks Used in Construction and Civil Engineering.

https://www.thomasnet.com/articles/plant-facility-equipment/types-of-bricks-used-in-construction-

and-civil-engineering/ [15 July 2020]](https://image.slidesharecdn.com/slideseramikfinal-200721121847/85/Manufacturing-Process-of-Clay-Bricks-22-320.jpg)

![6. HH Abdeen. (2016). Properties of Fired Clay Bricks Mixed with Waste Glass.

7. Anon. (2020). Characteristics of Good Bricks. https://civiltoday.com/civil-engineering-

materials/brick/69-characteristics-and-qualities-of-good-bricks-for-construction [16 July 2020]

8. Fernandes F.M., Lourenço P.B., Castro F. (2010) Ancient Clay Bricks: Manufacture and

Properties. In: Dan M.B., Přikryl R., Török Á. (eds) Materials, Technologies and Practice in

Historic Heritage Structures. Springer, Dordrecht.

9. Brick Industry Association. (2009). Technical Notes on Brick Construction, Manufacturing of

Brick TN9. Virginia: Brick Industry Association.

10. Parksim Sdn. Bhd. Official Web Portal

https://parksimbricks.com/ [8 July 2020]

References](https://image.slidesharecdn.com/slideseramikfinal-200721121847/85/Manufacturing-Process-of-Clay-Bricks-23-320.jpg)