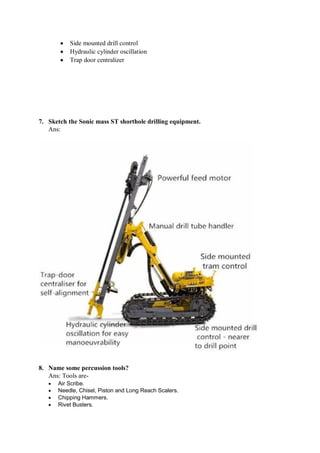

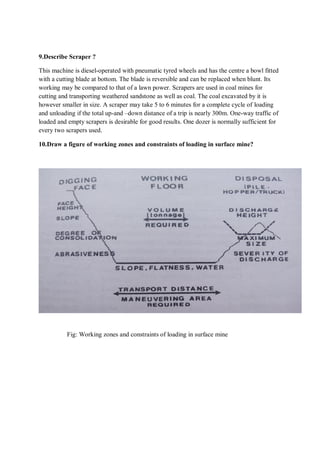

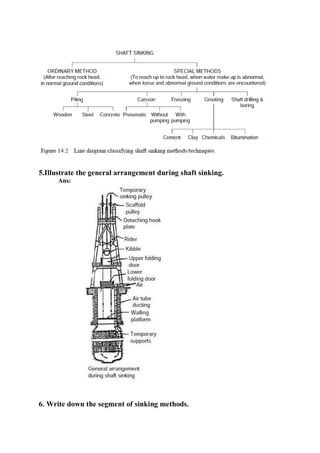

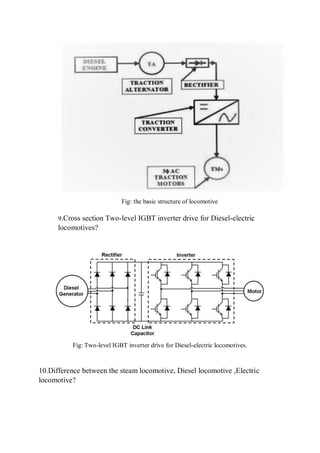

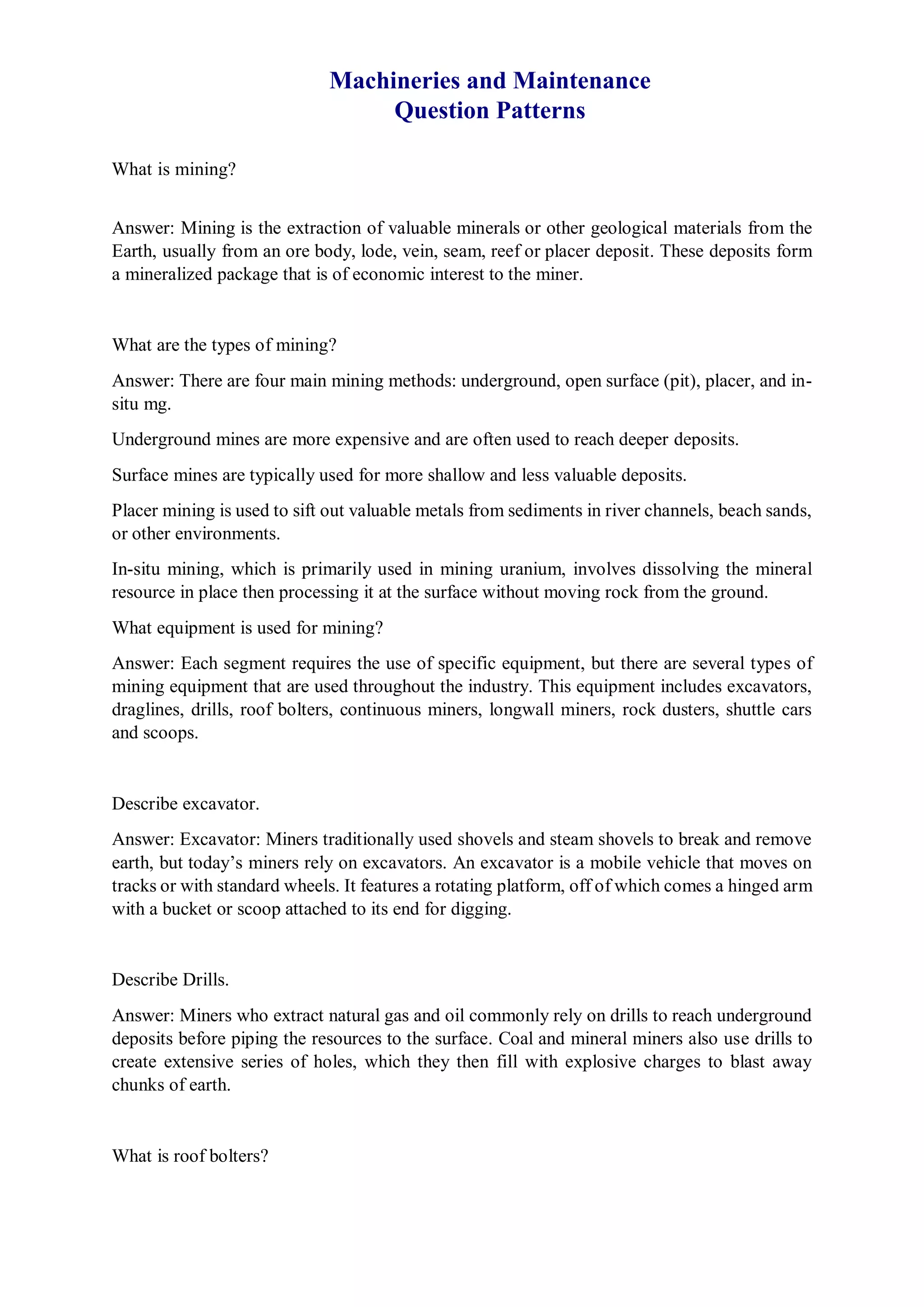

Mining is the extraction of valuable minerals or geological materials from the earth, with various methods including underground, surface, placer, and in-situ mining. The document describes different types of mining equipment, such as excavators, drills, roof bolters, shuttle cars, draglines, continuous miners, and rock dusters, as well as drilling techniques like rotary and percussion drilling. Additional operations, safety measures, and advantages and disadvantages of various drilling methods and equipment are also discussed.

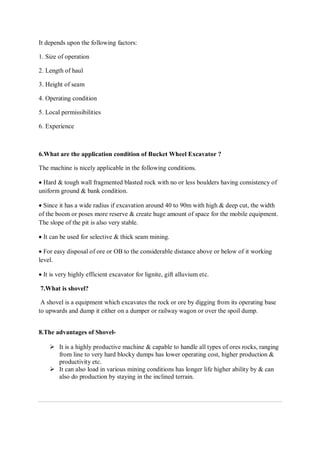

![4. List of components of oil drilling rings with sketch.

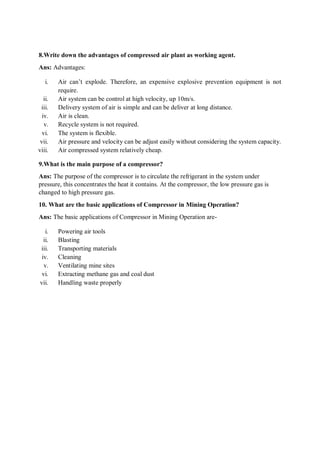

List of Items

1. Mud tank

2. Shale shakers

3. Suction line

4. mud pump

5. Motor or power source

6. Hose

7. Draw works

8. Standpipe

9. Kelly hose

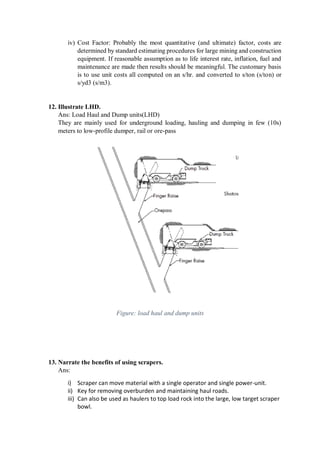

10. Goose neck

11. Traveling block

12. Drill line

13. Crown block

14. Derrick

15. Racking board

16. Stand of drill pipe

17. Setback (floor)

18. Swivel

19. Kelly drive

20. Rotary table

21. Drill floor

22. Bell nipple

23. Blowout preventer annular type

24. Blowout preventer pipe ram & blind ram

25. Drill string

26. Drill bit

27. Casing head or wellhead

28. Flow line

5. Define Auger drilling. How deep can an auger drill?

An auger is a drilling device, or drill bit, used for making holes in wood or in the ground.[1]

It

usually includes a rotating helical screw blade called a 'flighting' to act as a screw conveyor to

remove the drilled out material. The rotation of the blade causes the material to move out of

the hole being drilled.

Most augers dig about 3 ft. deep, but for deeper holes, ask for an extension rod, usually for no

extra fee. Deeper holes are typically required for footings for decks or other structures attached

to houses located in very cold climates where frost depths exceed 3 ft.](https://image.slidesharecdn.com/machineriesandmaintenance-210830194547/85/Machineries-and-Maintenance-Question-Patterns-for-Mining-students-4-320.jpg)