The document discusses various equipment used in screen printing, including:

- Photo emulsion, which hardens when exposed to UV light to create stencils on screens.

- Squeegees, which are used to push ink through screens to produce consistent results.

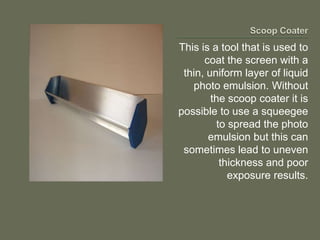

- Scoop coaters, which spread photo emulsion in a thin, even layer on screens.

- Film positives, which are opaque artworks used to expose screens.

- UV light sources needed to expose emulsion and create stencils.

- Clamps and tapes used to prepare screens for printing.