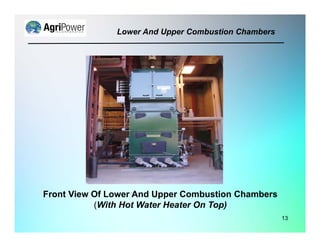

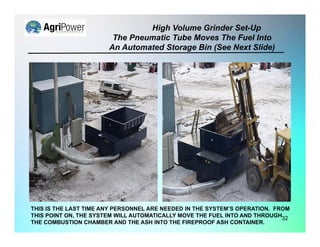

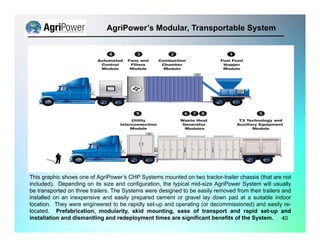

This document provides an overview of AgriPower's waste-to-energy systems that cleanly convert low-value biomass and other waste materials into heat energy and electric power. The systems address customers' needs to reduce waste disposal costs, fuel costs for energy generation, and comply with environmental regulations. AgriPower's proprietary technology includes combustion chambers that can efficiently use a wide variety of wet and dry waste fuels. The systems can produce heated air, hot water, steam, electricity, and refrigeration through add-on modules. They operate automatically without on-site personnel and provide significant economic and environmental benefits through fuel cost savings and waste conversion.