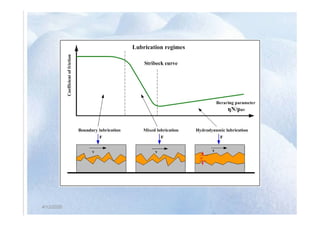

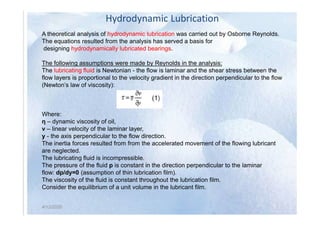

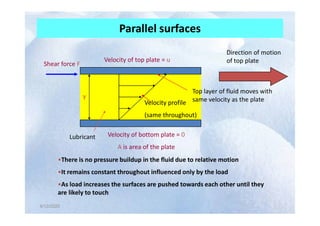

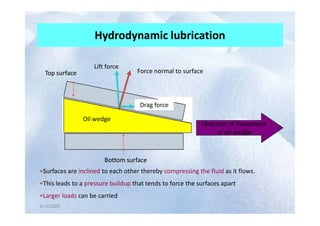

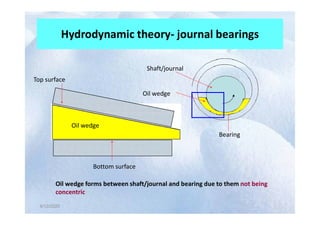

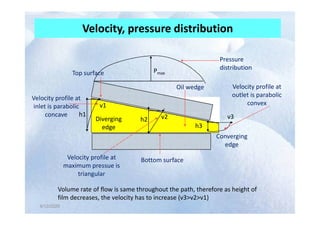

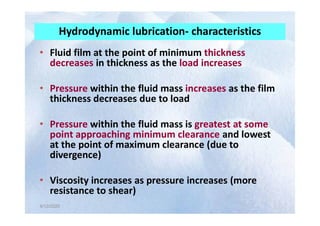

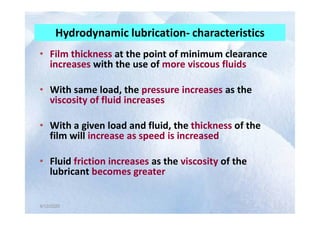

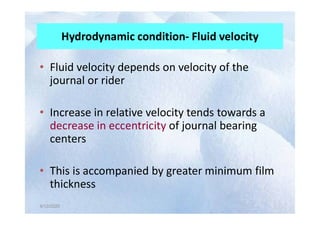

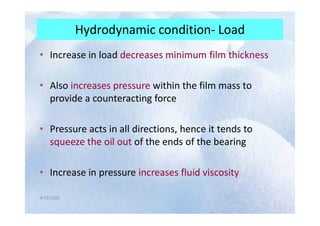

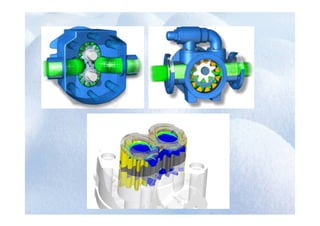

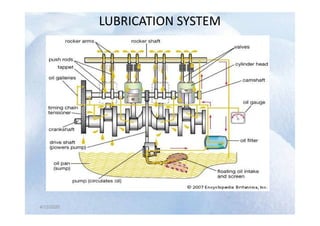

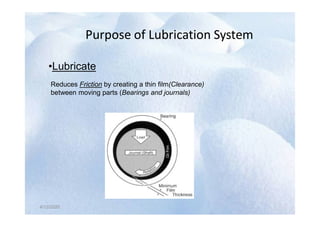

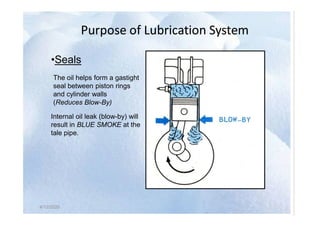

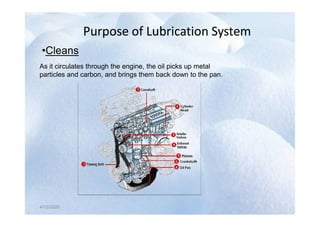

This document provides an overview of lubrication and lubrication systems. It begins with an introduction to lubrication, describing how lubricants reduce friction, wear, and heating between machine parts. It then discusses different lubrication regimes including boundary, mixed, and hydrodynamic lubrication. The document provides explanations of hydrodynamic and hydrostatic lubrication theories. It also describes lubrication systems and their purposes, such as lubricating parts, sealing, cleaning, cooling, absorbing shock, and absorbing contaminants.