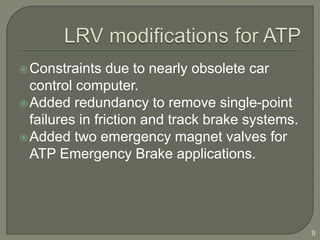

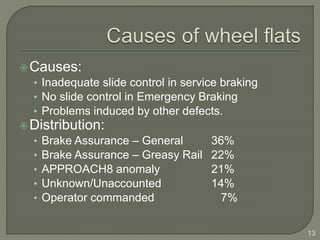

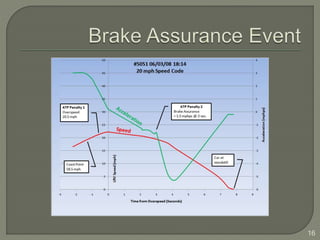

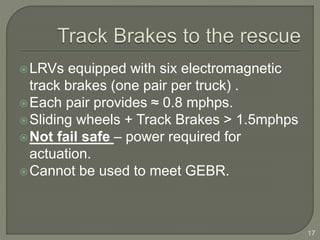

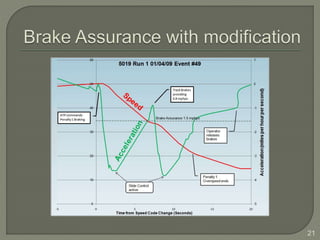

This document summarizes the wheel damage issue that occurred on a light rail system in 2008. An investigation found that inadequate brake inspection allowed wheel defects to occur fleet-wide. The underlying problem was determined to be poor integration of the train braking systems with the automatic train protection system. A temporary fix was implemented that energized track brakes on ATP overspeed commands, which increased braking to meet performance standards and eliminated further wheel damage.