Embed presentation

Downloaded 34 times

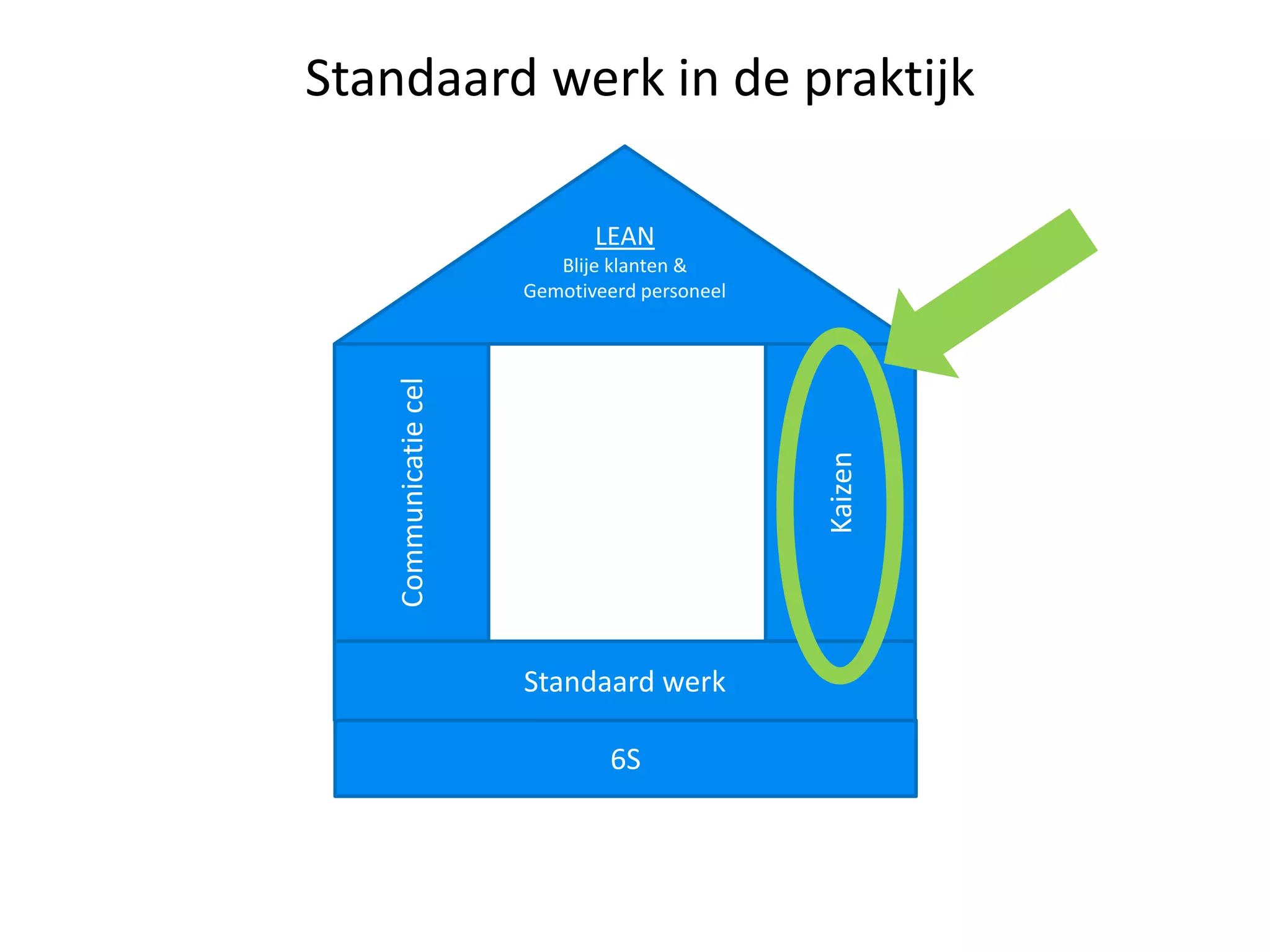

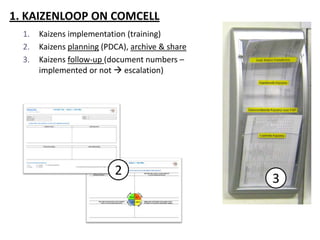

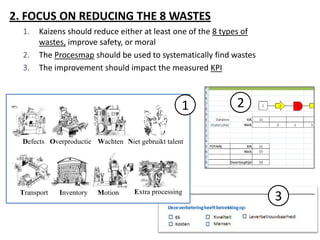

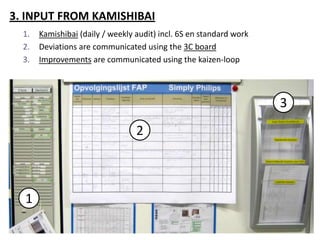

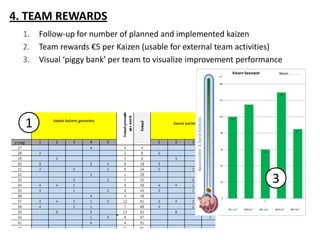

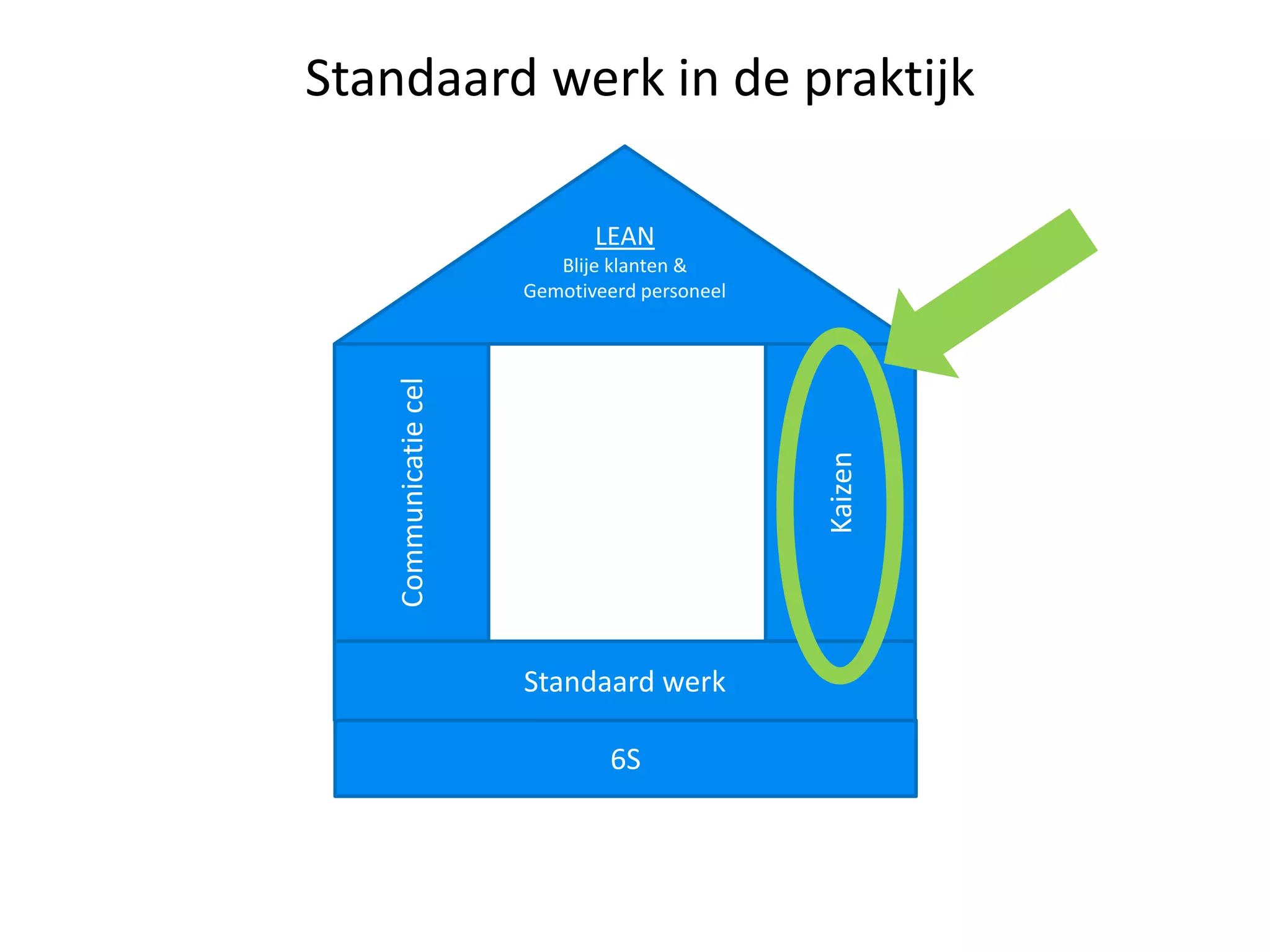

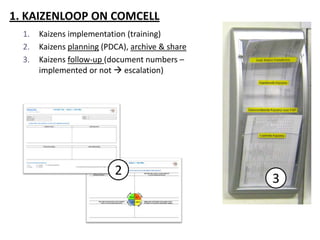

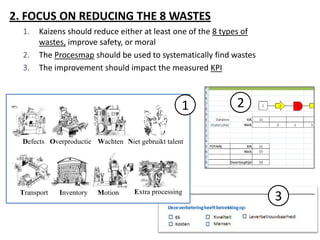

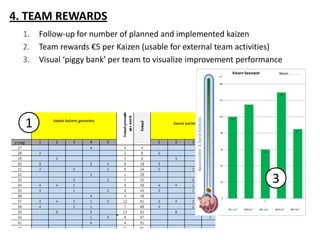

The document outlines the implementation of a Kaizen approach within a communication cell, focusing on reducing the eight types of waste and enhancing customer satisfaction and employee motivation. It includes processes for planning, archiving, and following up on Kaizen initiatives, along with team rewards for successful implementations. Additionally, it emphasizes using tools like Kamishibai for audits and a visual system to track improvement performance.