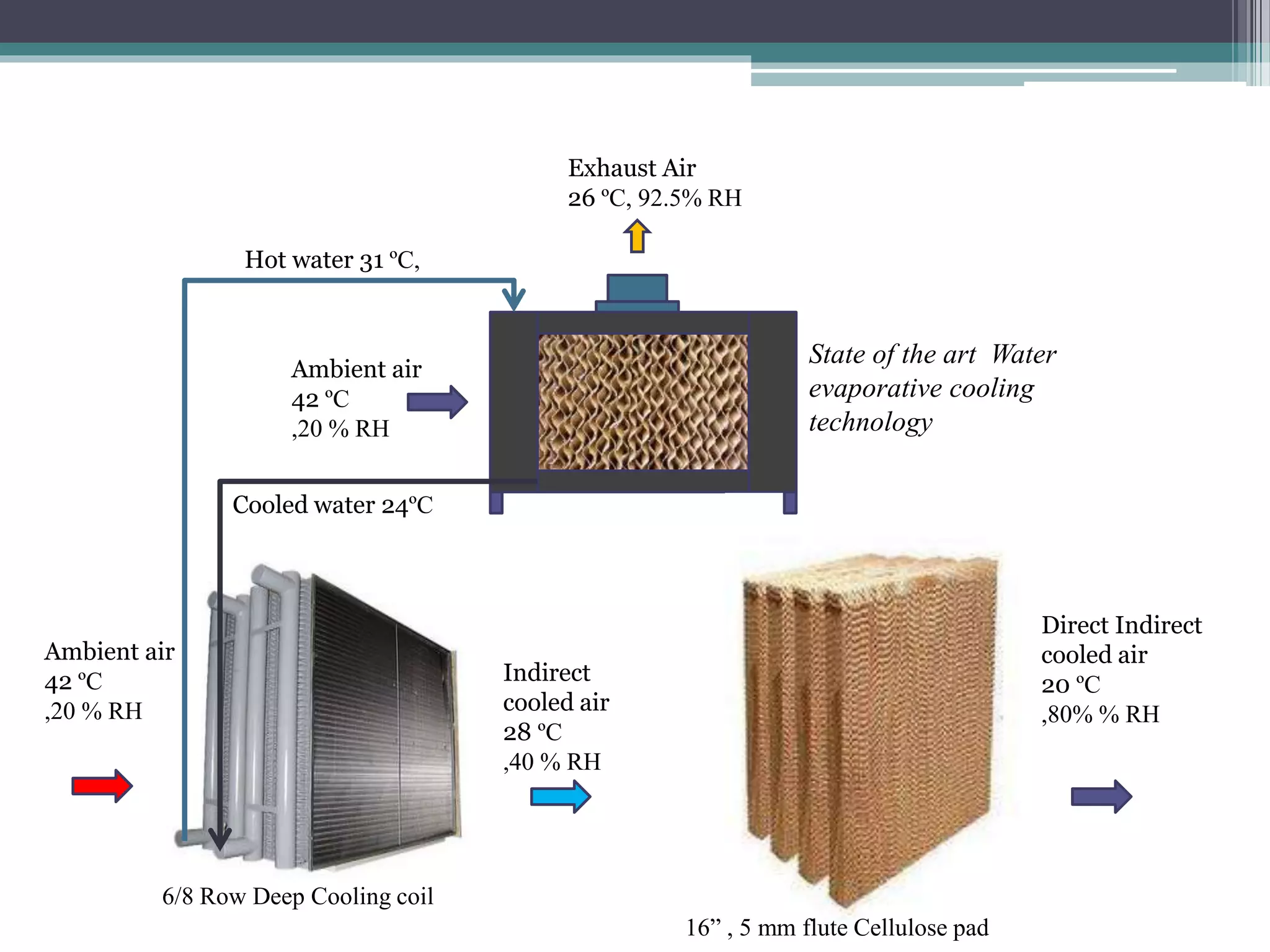

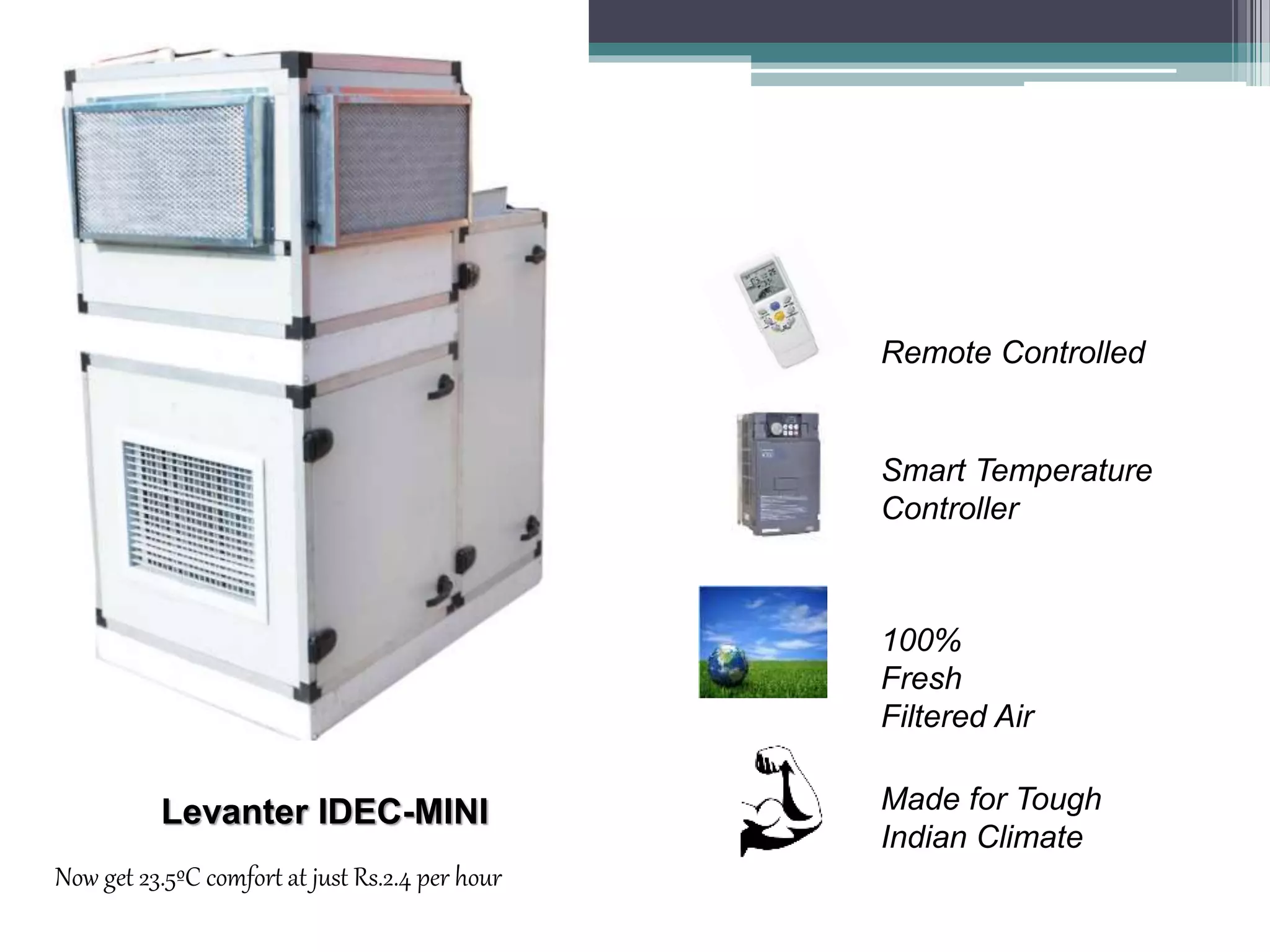

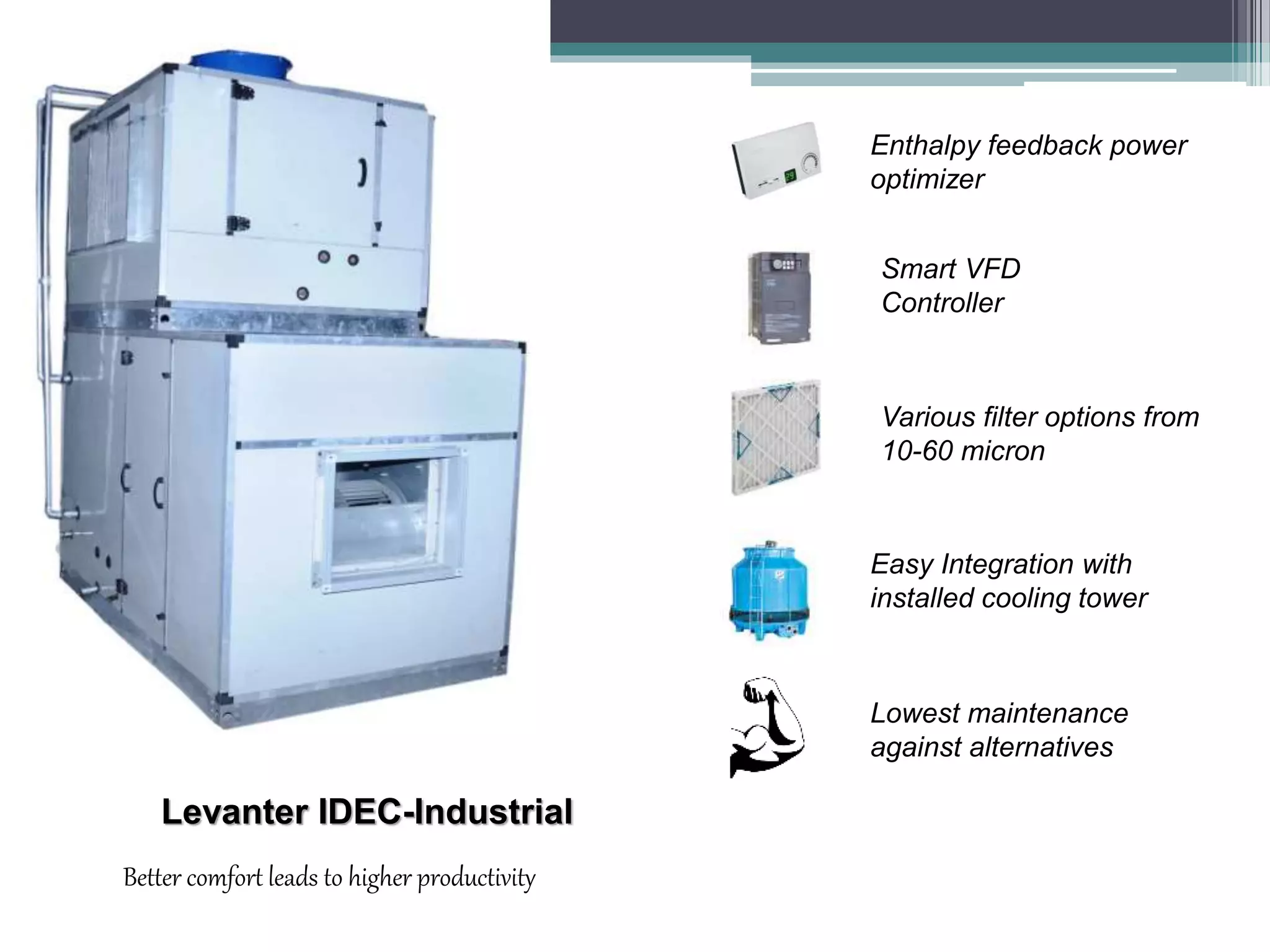

The document discusses indirect-direct evaporative cooling (IDEC) air systems. IDEC uses two stages - first air is cooled indirectly in a heat exchanger without adding moisture. This cooled air is then further cooled directly through evaporation by adding moisture before being distributed. IDEC provides up to 40% lower humidity and 60% lower power consumption than alternative systems. Various IDEC models are presented along with their specifications and components. Performance graphs show the system can maintain cooler, consistent temperatures even at higher outdoor temperatures and humidity levels. Optional features and contact details are also listed.