Modular Coordination in buildings and construction.pptx

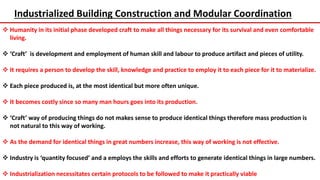

- 1. Industrialized Building Construction and Modular Coordination Humanity in its initial phase developed craft to make all things necessary for its survival and even comfortable living. ‘Craft’ is development and employment of human skill and labour to produce artifact and pieces of utility. It requires a person to develop the skill, knowledge and practice to employ it to each piece for it to materialize. Each piece produced is, at the most identical but more often unique. It becomes costly since so many man hours goes into its production. ‘Craft’ way of producing things do not makes sense to produce identical things therefore mass production is not natural to this way of working. As the demand for identical things in great numbers increase, this way of working is not effective. Industry is ‘quantity focused’ and a employs the skills and efforts to generate identical things in large numbers. Industrialization necessitates certain protocols to be followed to make it practically viable

- 2. Industrialized Building Construction and Modular Coordination Advantages & Disadvantages Advantages: 1. Faster production 2. More economical for mass production 3. Manage Quality control 4. Faster Research and development makes improvement possible Disadvantages: 1. Proto typing of product 2. Flexibility of use is reduced 3. Reliance on larger setups for producing simplest of utilitarian objects.

- 3. Industrialized Building Construction and Modular Coordination Industialization of Building Construction Industrialization of entire building as an product is difficult since every building is different than other in various aspects i.e. site, designed use, climate response etc. It is possible to industrialize the production of components if building and assemble them on site. A system of such component manufacturing and then assembly can be set up as an industry. Industrialized Building System can be defined as building systems in which structural components are manufactured in a factory, on or off site, transported and assembled into a structure with minimal additional site works. It an be introduced to achieve the target of faster completion with mass production of the building elements in places out of its final location in a building. It has been proved to be beneficial to construction activites in developed countries, especially where fast construction is a necessity and Human labour is costly. In India, process of industrialization of building construction is slower since human labour is cheap and we are not very time conscious.

- 4. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Characteristics Of IBS One of the major characteristics of the IBS is the Industrial production of components through prefabrication, “OR” sometimes highly mechanized in-situ processes i.e. permanent steel formworks, tunnel forms, etc. Reduced labor during prefabrication of components and site works. Modern design and manufacturing methods involving Information Technology like usage of Computer Aided design (CAD) and Computer Aided Manufacturing (CAM). Systematic Quality Control i.e ISO 9000 principles. Open Building Concept- permitting hybrid applications, and adaptable to standardization and MC (Modular Coordination)

- 5. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Classification Of IBS There are various Industrialized Building Systems (IBS) used throughout the world, and they can be classified into three major categories. These categories are:- 1. Frame or Post & Beam System. 2. Panel System. 3. Box system. Frame or post & Beam system is the simplest as it has always been(in our vernacular architecture) a preformed elements of stone or wood etc. however, the standardization of sizes were more dependent on the availability of material. Box system is the most sophisticated due to its assembly and handling issues.

- 6. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS)

- 7. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) FRAME SYSTEM: Frame structures may be defined as those structures that carry the loads through their beams and girders to column and to the ground. Their important feature is the capacity to transfer heavy loads over large spans. Used in the construction of bridges, parking lots, warehouses, industrial buildings, sport facilities and so on.

- 8. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) FRAME SYSTEM: Frame structures may be defined as those structures that carry the loads through their beams and girders to column and to the ground. Their important feature is the capacity to transfer heavy loads over large spans. Used in the construction of bridges, parking lots, warehouses, industrial buildings, sport facilities and so on.

- 9. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) FRAME SYSTEM: Frame structures may be defined as those structures that carry the loads through their beams and girders to column and to the ground. Their important feature is the capacity to transfer heavy loads over large spans. Used in the construction of bridges, parking lots, warehouses, industrial buildings, sport facilities and so on.

- 10. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) PANEL SYSTEM Panel system may be defined as those structures that carry the load through large floor and wall panels. Concrete panel systems are extensively used in Europe for high rise building for ease of construction purpose. Used in Hollow core slabs, Interior & Exterior Wall.

- 11. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) PANEL SYSTEM Panel system may be defined as those structures that carry the load through large floor and wall panels. Concrete panel systems are extensively used in Europe for high rise building for ease of construction purpose. Used in Hollow core slabs, Interior & Exterior Wall.

- 12. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) BOX SYSTEM Box system may be defined as those systems that use 3D modules (or boxes) for fabrication of habitat units. The main features of this system are in the internal stability as it can withstand load from various directions. Require only large prefabricated sections to be transported or handled at one time.

- 13. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) WHY IBS??? Scenario in construction industry compared to other sectors is that the construction industry suffers from low productivity, safety and quality control. Due to the traditional labor-intensive practices, the 3- D Syndrome (Dirty, Difficult & Dangerous) has always been associated with the construction industry. IBS is a good solution for these kind of problems of the construction industry- messy sites, high wastages, labor intensive works, low quality work, delays.

- 14. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) ADVANTAGES 1. Reduction of site labor; Low site workers requirement due to simplified construction methods. 2. Minimal wastage; Reduction of construction waste with the usage of the standardized components and less in-site works. 3. Less site material; Reduction of construction materials at sites through usage of pre-fabricated components. 4. Cleaner environment ; Cleaner sites due to lesser construction waste.

- 15. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) ADVANTAGES 5. Controlled quality; controlled and highly aesthetic end products through the processes of controlled prefabrication and simplified installations. 6. Neater and safer site; Safer construction sites due to the reduction of site workers, materials and construction waste. 7. Faster Project Completion; Faster completion of construction projects due to the usage of standardized pre-fabricated components and simplified installation processes. 8. Lower total construction cost;

- 16. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Principles for industrialised Building systems; 1. Clarity in objectives to be achieved through Industrialised component 2. Standardisation of material and dimensions. 3. Material and Dimensional consistency. 4. Minimum number of different sizes required. 5. Inter-chageability in locating the component. 6. Simplified operational procedure.

- 17. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Principles for industrialised Building systems; 1. Clarity in objectives to be achieved through Industrialised component 2. Standardisation of material and dimensions. 3. Material and Dimensional consistency. 4. Minimum number of different sizes required. 5. Inter-chageability in locating the component. 6. Simplified operational procedure. Most of the above principles can be imbibed in IBS by following the concept of Modular Coordination.

- 18. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Modular Coordination; Module is a unit with appropriate dimensions to form the basic unit which can be employed repeatedly to form a complete building/building element. Modular coordination is a concept of coordination of dimension and space, in which buildings and components are dimensioned and positioned in a term of a basic unit or module, known as ‘1M’ which is equivalent to 100 mm • It is internationally accepted by the International Organization for Standardization (ISO) and many other countries. • Modular coordination can facilitate the achievement of greater productivity in the building industry by virtue of its ability to discipline the dimensional and spatial coordination of a building and its components. . Modular Coordination is a useful design tool that provides useful design principles and rules which combine freedom in architectural planning and free choice of construction method, with the possibility of incorporating standardized modular components in the project.

- 19. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Aim of Modular Coordination; 1. The principle object is to assist rationalization and industrialization within the construction activity, by standardization in such a way that components may be manufactured on an industrial scale and erected efficiently on site, thereby improving quality and cost effectiveness of building. 2. Facilitates cooperation between building designers, manufacturers, distributors, contractors and authorities. 3. In design work, to simplify the preparation of building drawings in relation to the construction system and methodology. 4. Optimizes the number of standard sizes of building components. 5. Rationalize and simplify the on-site activities and thereby minimize the necessity of continues supervision and involvement of skilled labour on site by rationalizing setting out, positioning and assembly of building components. 6. Encourages as far as possible the interchangeability of components, in whatever materials, forms or methods of manufacture. 7. Ensures dimensional coordination between installation(equipment, storage units, other fitted furniture, etc.) as well as with the rest of the building.

- 20. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Modular coordination is essentially based on: a. The use of modules ( basic modules and multi -modules) b. A reference system to define coordinating spaces and zones for building elements and for components which form them. c. Rules for locating building elements within the reference system. d. Rules for sizing building components in order to determine their work sizes. e. Rules for defining preferred sizes for building components and coordinating dimensions for buildings.

- 21. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Modules: Standard unit size used to coordinate the dimensions of buildings and components MODULES Basic module M = 100 mm The basic module is the fundamental unit of size in modular co-ordination) . The co-ordinating sizes of building components, of the parts of buildings they form and of buildings themselves shall be multiples of the basic module. Multi-Module 2M, 3M . . Multimodules are selected multiples of the basic module; differentmulti modules will suit particular applications.

- 22. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Modules: Standard unit size used to coordinate the dimensions of buildings and components Sub-Module M/2, M/4 For sizing of components requiring increment smaller than ‘M’ Horizontal planning module Mh= 3M (300mm) The horizontal planning module for structural framework is based on the functional requirements of the building and the components to be used for economic design. Hence the preferred Module for Building design is 3M. Vertical Planning Module Mv= 1M (100mm) For buildings it could also be 3M sometimes.

- 23. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Tolerances: •The permissible deviation from a specified value of a structural dimension, often expressed as a percent or some times as specific dimension i.e. ‘5 mm rule’ in modular building construction. • Manufacturing variables make it impossible to produce a part of exact dimensions; hence the designer must be satisfied with manufactured parts that are between amaximum size and a minimum size. • Tolerance is the difference between maximum and minimum limits of a basic dimension. • For instance, in a shaft and hole fit, when the hole is a minimum size and the shaft is a maximum, the clearance will be the smallest, and when the hole is the maximum size and the shaft the minimum, the clearance will be the largest.

- 24. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Reference System: The reference system is a system of points, lines and planes to which the sizes and positions of building components orassemblies relate. A reference system should be used during the design stage, and may also form the basis of the system of lines from which measurements on site are set out. MODULAR SPACE-GRID A modular space-grid is a three-dimensional system of planes within which a building and its components are located. The distance between the planes in such a system is equal to the basic module, or to a multimodule.

- 25. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Reference System: MODULAR SPACE-GRID A modular space-grid is a three-dimensional system of planes within which a building and its components are located. The distance between the planes in such a system is equal to the basic module, or to a multimodule. BASIC MODULAR GRID The fundamental modular grid is that in which the spacing of consecutive parallel lines is equalb to the basic module. 1M x 1M.

- 26. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Reference System: INTERRUPTIONS AND DISPLACEMENTS OF MODULAR GRID It may be necessary to interrupt a modular grid (for example, in order to accommodate dividing elements). The width of the zone of interrupt ion of the modular grid may be modular or non- modular (neutral zone) .

- 27. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Reference System: Terms used in modular planning 1. Modular line A line of a modular reference system. 3. Modular zone A zone between modular planes. 5. Planning grid A reference grid for the plan of a building. 7. Space grid A three-dimensional network of reference lines. 8. Modular space grid A space grid in which the distance between consecutive parallel lines is the basic module or a multiple thereof 2. Modular plane A plane of a modular reference system . 4. Modular size The size of a modular dimension. 6. Modular grid A reference grid in which the distance between consecutive parallel lines is the basic module or a multiple thereof.

- 28. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Reference System: Controlling Reference system Controlling plane A plane in a planning grid by reference to which the theoretical positions of structural, elements are determined. Controlling zone A zone between controlling planes, provided for a floor, roof, load bearing wall or column. Controlling dimension A dimension between controlling planes, such as floor-to-floor height, distance between axes of columns, thickness of controlling zone. Modular floor plane A horizontal modular plane spreading continuously over the whole of each storey of a building and coinciding with the upper surface of floor finish. Floor-to-floor height The dimension between the upper controlling plane of one floor zone and the upper controlling plane of the floor zone immediately above. Floor-to-ceiling height The dimension between the upper controlling plane of one floor zone and the lower controlling plane of the floor o r roof zone immediately above

- 29. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Reference System: Controlling Reference system Floor-to-roof height The height between the upper controlling plane of one floor and the upper controlling plane of the roof immediately above. Height of roof zone The dimension between the controlling plane of a ceiling and the upper controlling plane of the roof immediately above.

- 30. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Reference System: Controlling Reference system

- 31. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) The Grid STRUCTURAL GRID • used to locate structural components such as beams and columns. PLANNING GRID • based on any convenient modular multiple for regulating space requirements such as rooms. CONTROLLING GRID • based on any convenient modular multiple for location of internal walls, partitions dc. BASIC MODULE GRID • used for detail location of components and fittings. • All the above grids, being based on a basic module, are contained one within the other and are therefore interrelated. • These grids can be used in both the horizontal and vertical planes thus forming a three dimensional grid system. • If a first preference numerical value is given to M dimensional coordination is established.

- 32. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) The Grid

- 33. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) The Grid: The modular grid network defines the space into which dimensionally coordinated components must fit. An important factor is that the component must always be undersized to allow for the joint which is sized by the obtainable degree of tolerance and site assembly.

- 34. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) The Grid:

- 35. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach: Face/ Boundary Planning It is used to position components of construction in relation to the grid. • It is represented by a pair of parallel lines. • The component is placed with the faces on the lines. • The distance between the sets of parallel lines is always modular. • It involves introduction of neutral zones which are usually non-modular.

- 36. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach: Combination of Face and Axial Planning In the planning process, it is easier to begin with the modular grid and determine the positions of the major elements using the axial planning. • The face planning will then be introduced for the positioning and sizing of various components and also to design the joints.

- 37. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach: Vertical Planning

- 38. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach: Examples

- 39. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach: Examples

- 40. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach: Examples

- 41. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Positioning of building elements; Floor Slabs Depth will be in sub-modular increments of 0.5M (50mm) or0.25M (25mm). Precast slabs are available in width of 6M. Length can be varied according to the requirements. These dimensions fits the structural grid, thus there is no wastage. The FLOOR ZONE is the space allocated for the floor assembly. It extends from the reference plane of ceiling to that of finished floor above it.

- 42. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Positioning of building elements; Walls Length is determined by the chosen planning grid Sub-modular increments of 0.5M and 0.25M are recommended for thickness of walls. Allowances must be given for thickness of finishes to be used.

- 43. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Positioning of building elements; Walls

- 44. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Positioning of building elements; Walls

- 45. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Positioning of building elements; Walls

- 46. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Positioning of building elements; Walls

- 47. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Positioning of building elements; Staircase Size of the tread=250mm On plan, the width of coordinating spaces accommodates the two flights and possible space in between. Flight and landing, both the dimensions are modular.

- 48. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Positioning of building elements; Staircase Size of the tread=250mm In section, the stairs will be located in between the floor coordinating lines. The dimension of the total width, the length of flight and the width of landing must be in multiples of 1M and 0.5M.

- 49. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Prefered dimension 0f elements; Staircase Flooring and Roofing Scheme - Precast slabs or other precast structural flooring units: • Length - Nominal length shall be in multiples of 1 M; • Width - Nominal width shall be in multiples of 0.5 M; and • Overall Thickness - Overall thickness shall be in multiples of 0.1M. Beams • Length - Nominal length shall be in multiples of 1 M; • Width - Nominal width shall be in multiples of 0.1 M; and • Overall Depth - Overall depth of the floor zone shall be in multiples of 0.1M.

- 50. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Planning Approach : Preferred dimension 0f elements; Staircase Columns • Height - Height of columns for industrial and other building1 M; & • Lateral Dimensions - Overall lateral dimension or diameter of columns shall be in multiples of 0.1 M. Walls • Thickness - The nominal thickness of walls shall be in multiples of 0.1 M. Staircase • Width - Nominal width shall be in multiples of 1M. Lintels • Length - Nominal length shall be in multiples of 1 M; • Width - Nominal width shall be in multiples of 0.1 M; and • Depth - Nominal depth shall be in multiples of 0.1 M. Sunshades/Chhajja Projections • Length - Nominal length shall be in multiples of 1 M.

- 51. Industrialized Building Construction and Modular Coordination Industialization of Building Construction: Industrialised Building Systems (IBS) Modular Coordination MODULAR COORDINATION requires considerable effort and discipline and the process may not be pleasant, atleast initially. However, in the long term, it is likely to payoff when the tool is understood and used effectively; more so if implemented throughout the industry.