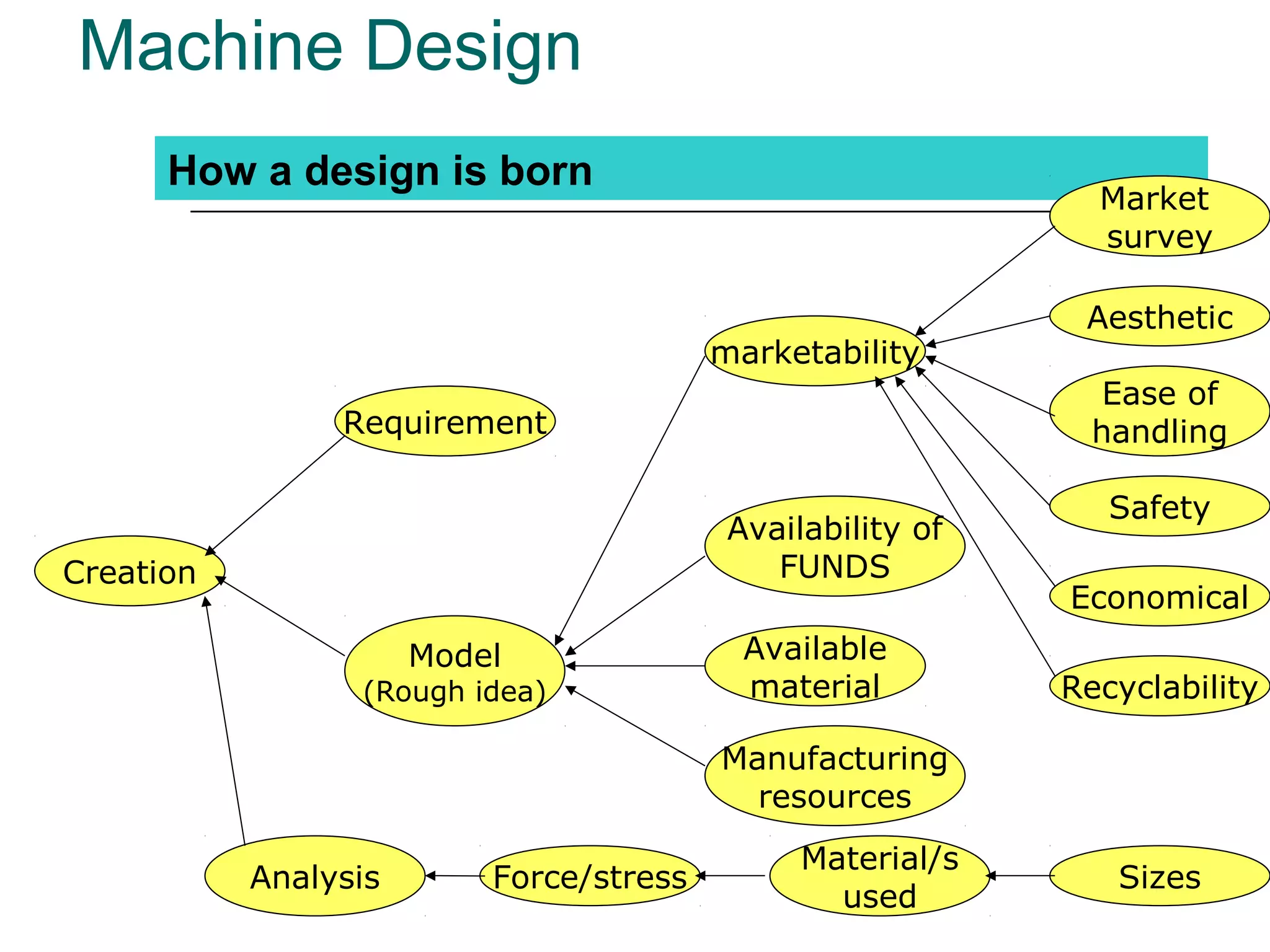

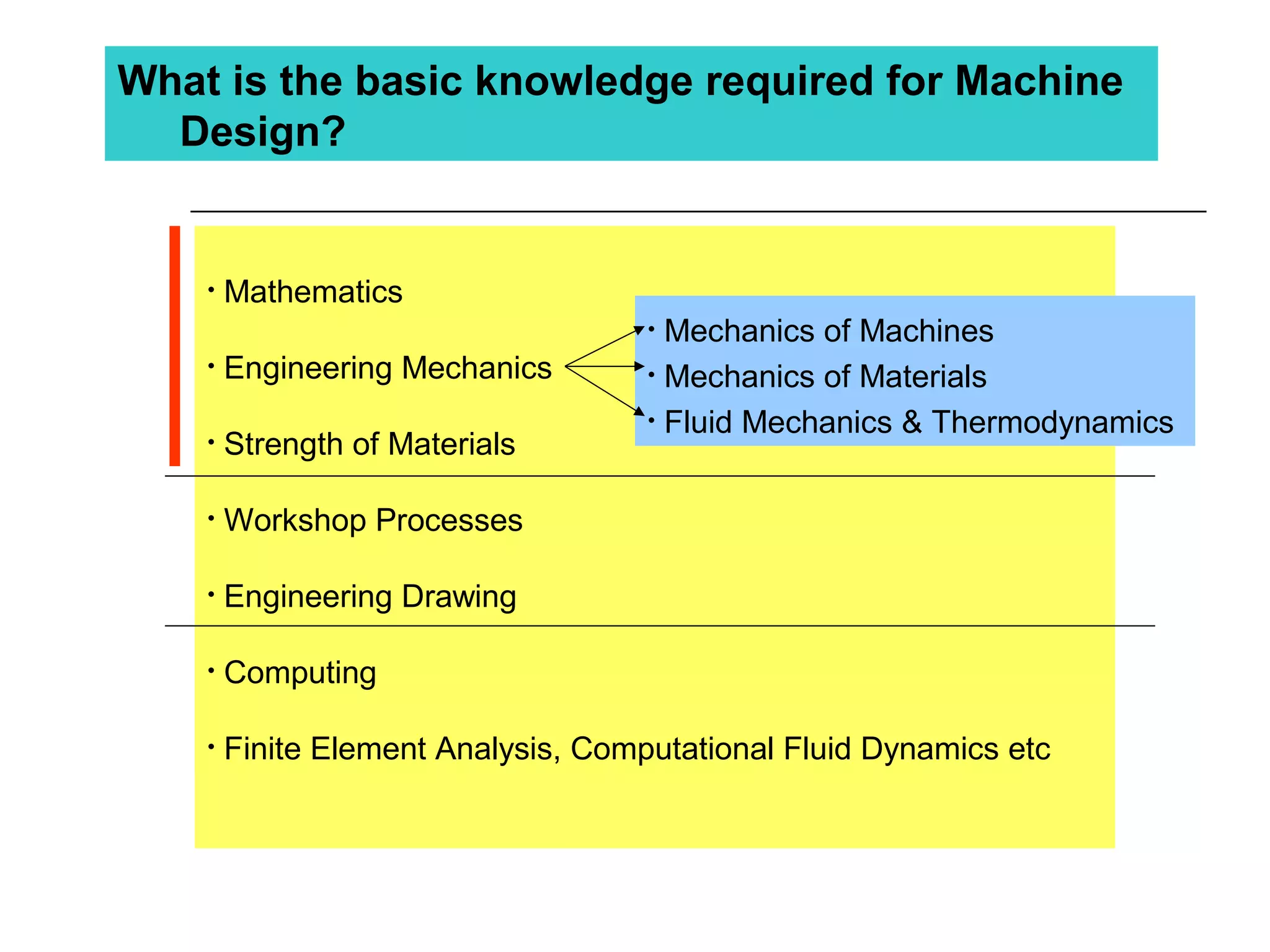

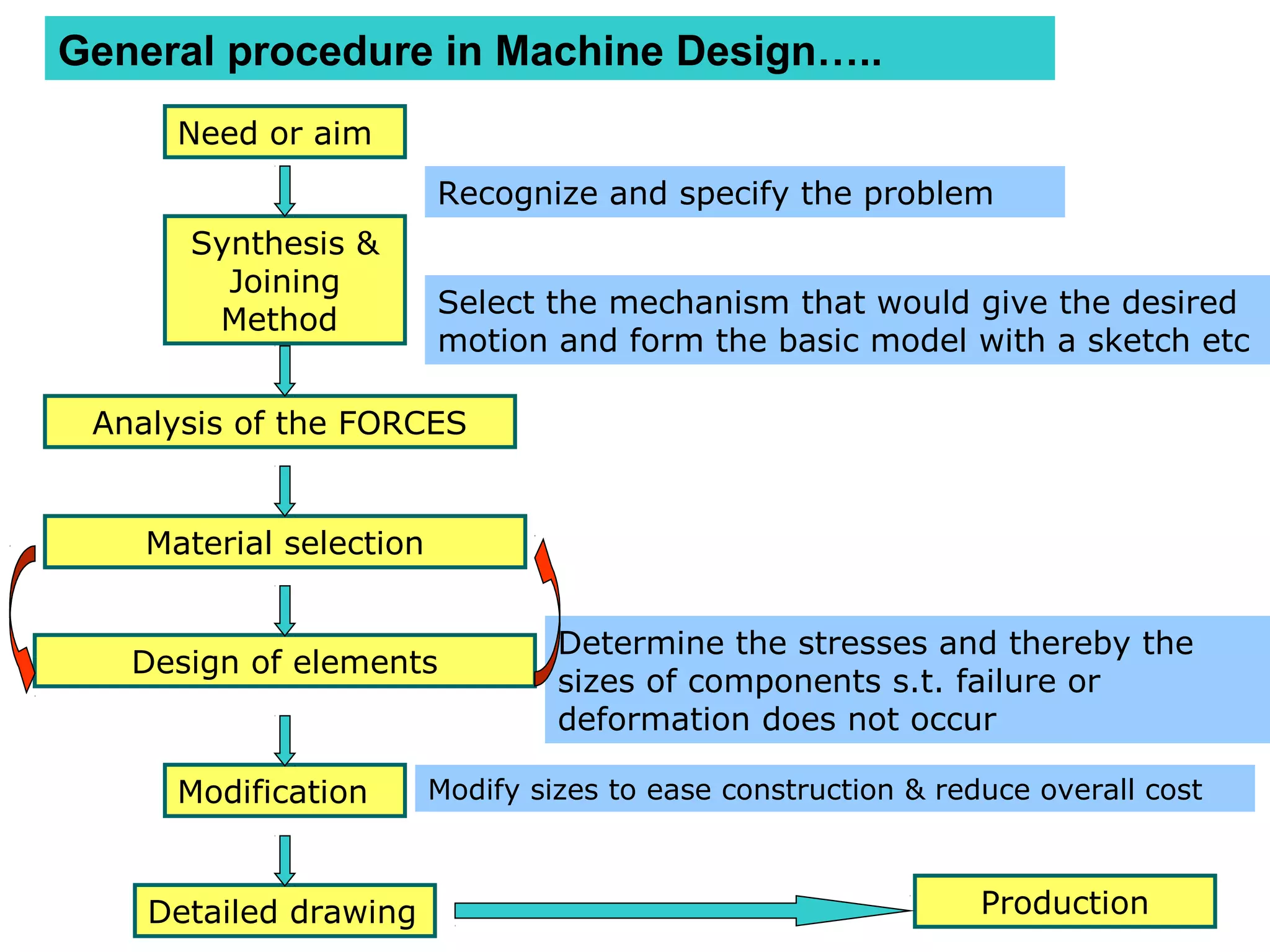

Machine design is the process of creating new machines and improving existing machines so they are economical to produce and operate. The basic knowledge required for machine design includes mathematics, engineering mechanics, strength of materials, workshop processes, engineering drawing, computing, and finite element analysis. The general procedure in machine design involves recognizing the problem, selecting an appropriate mechanism, analyzing stresses on components to determine sizes, modifying sizes to reduce costs, and producing the design. A design engineer is expected to have in-depth technical knowledge, communicate effectively, solve problems innovatively, and stay up to date with technological advances.