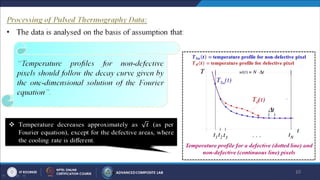

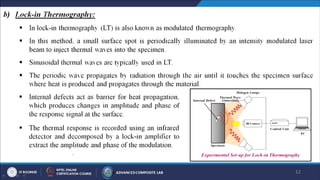

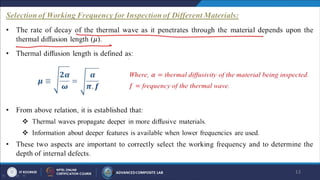

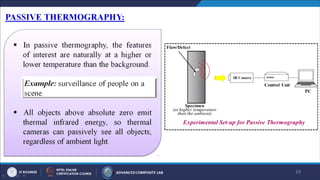

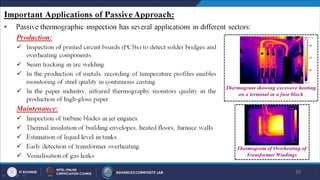

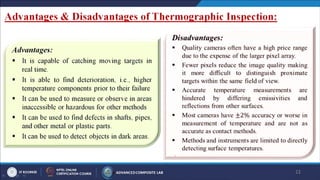

The document outlines various methods of leak testing and thermal inspection, highlighting the use of temperature-sensitive materials like thermochromic paints, heat-sensitive paper, and thermally quenched phosphors. Thermography is identified as the principal technique for mapping temperature variations to detect flaws in materials, utilizing transient or steady-state heating methods. The document also discusses thermal inspection procedures that balance heating and cooling, relying on temperature gradients to identify defects effectively.