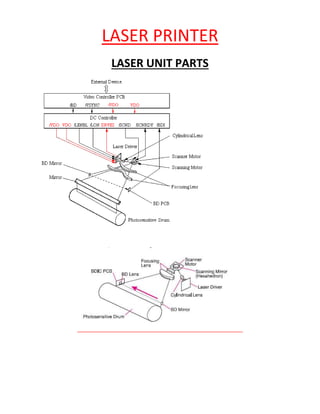

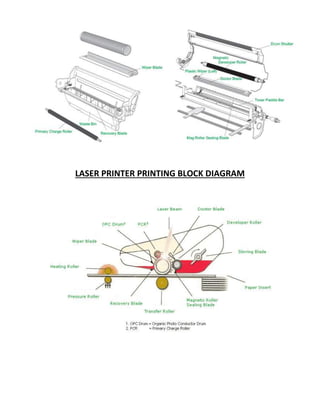

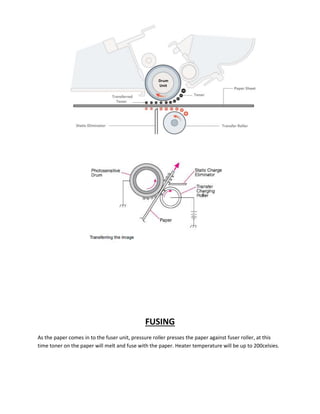

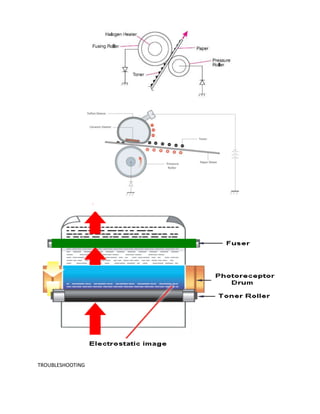

The document describes the main components and functions of a laser printer. It explains that the laser unit generates a laser beam to write data onto the OPC drum. The main PCB receives data from the computer and controls printer functions, while the formatting PCB converts data for the laser unit. It then outlines the printing process, which involves cleaning, charging, writing, developing, transferring, and fusing toner onto paper.