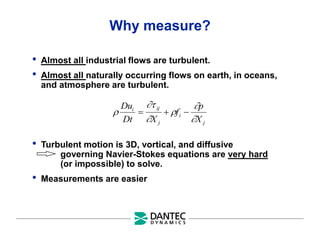

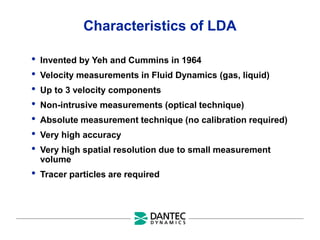

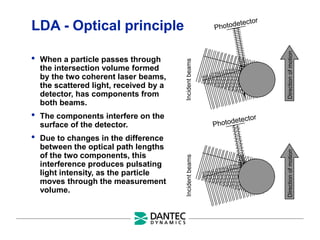

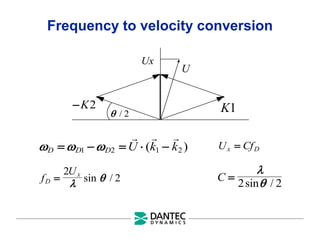

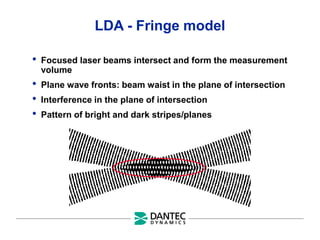

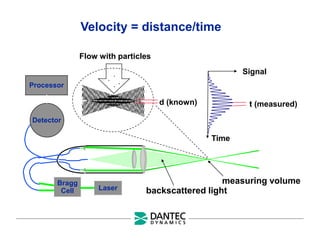

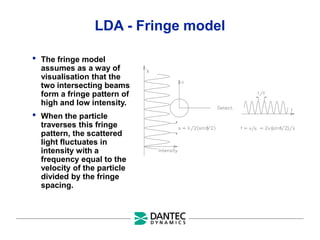

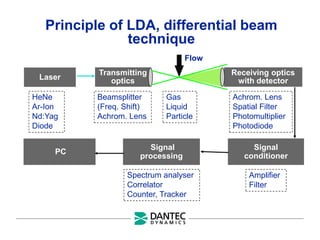

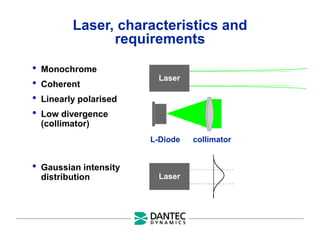

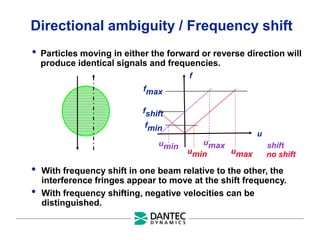

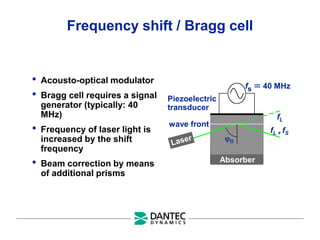

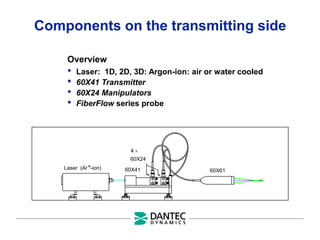

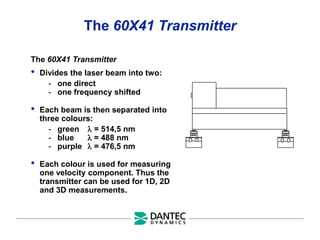

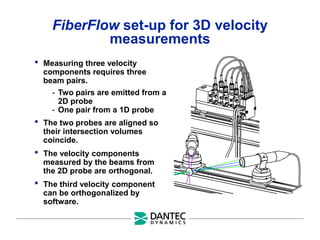

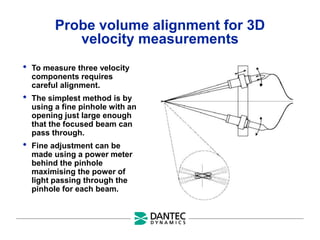

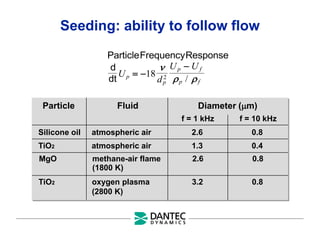

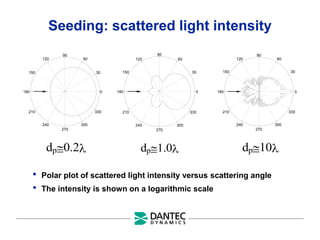

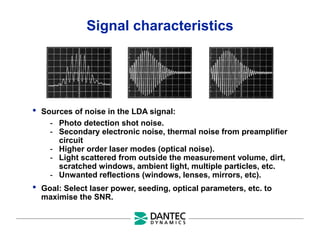

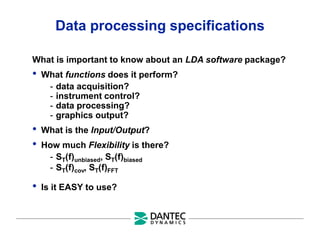

The document provides a comprehensive overview of Laser Doppler Anemometry (LDA), discussing its principles, optical systems, and various applications for measuring fluid dynamics in turbulent and laminar flows. It emphasizes the importance of accurate flow measurements in industrial and engineering contexts and outlines the technical characteristics of the LDA system, including the seeding requirements and signal processing techniques. Additionally, it highlights the instrumentation and configurations necessary for effective LDA measurements, especially in complex flow scenarios.