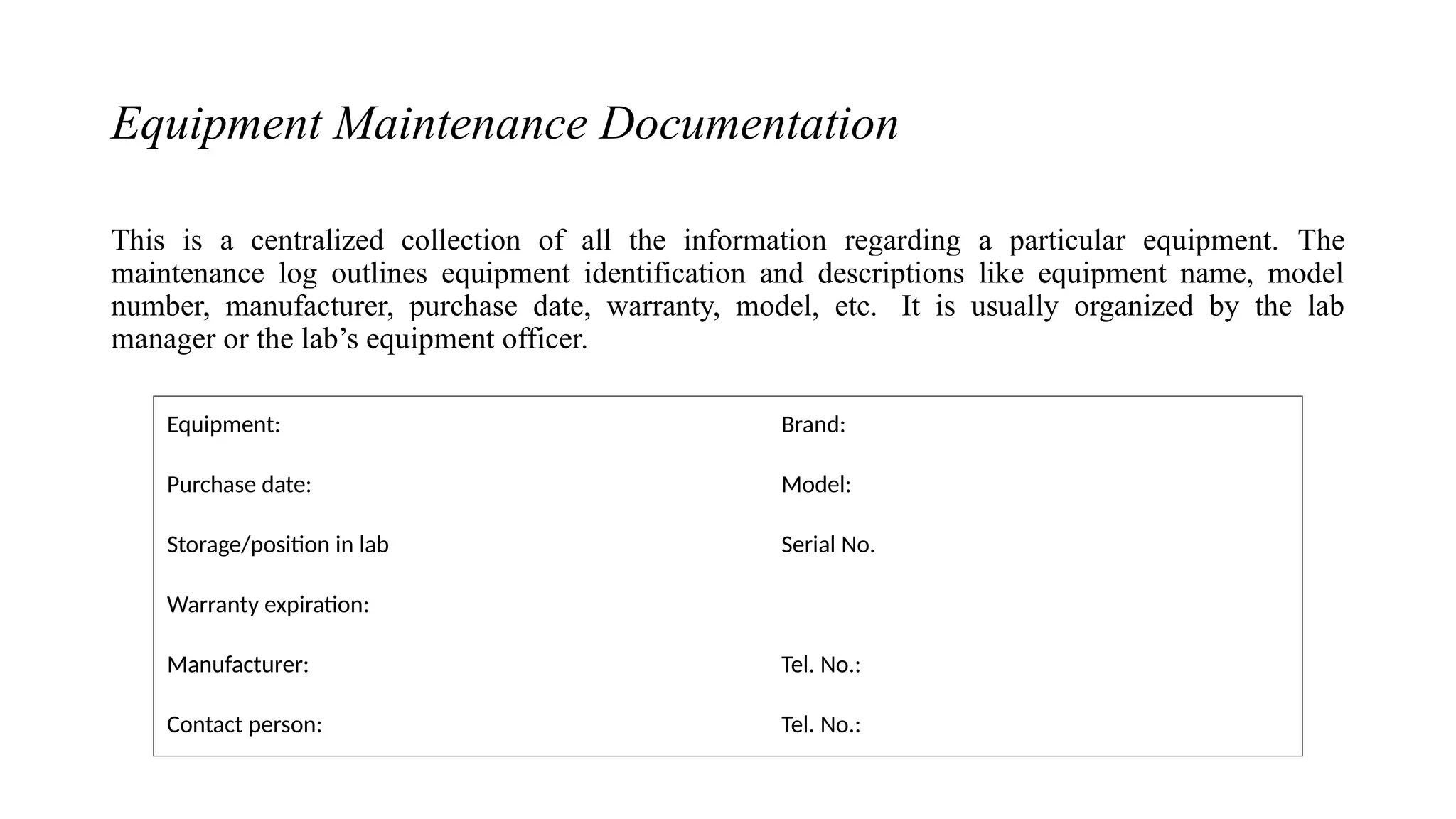

The document outlines essential practices for the care and maintenance of laboratory equipment to ensure quality assurance. Key practices include regular cleaning, calibration, and timely repairs, alongside the importance of having standard operating procedures and training for staff. A preventive maintenance program is also emphasized to minimize interruptions and maximize operational efficiency.