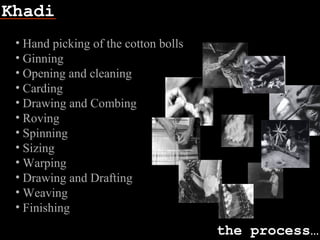

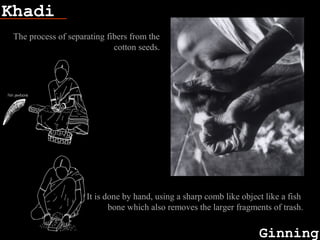

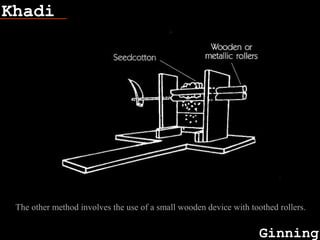

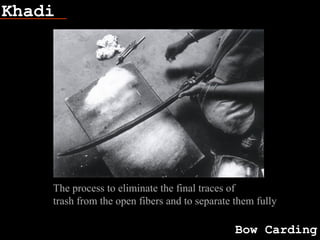

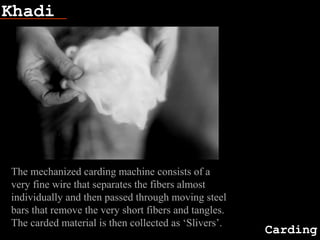

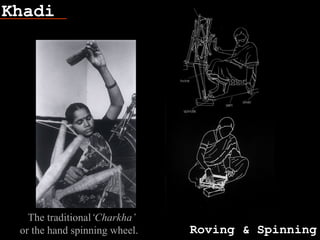

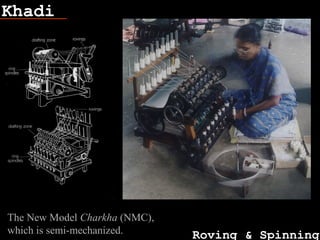

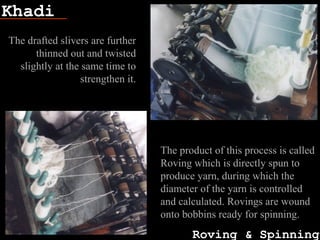

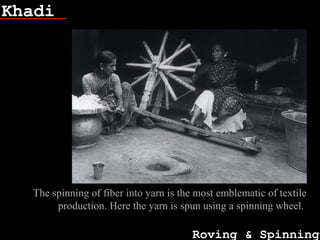

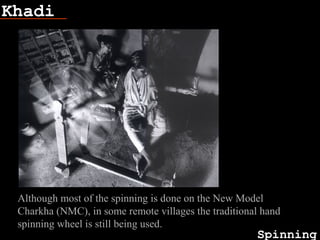

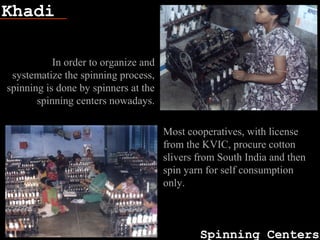

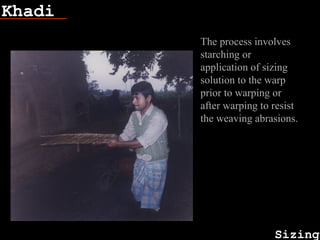

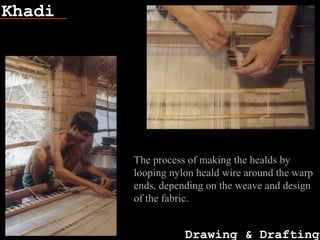

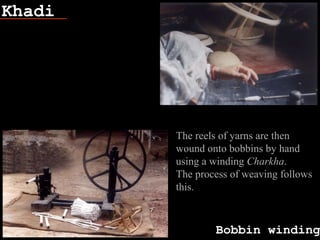

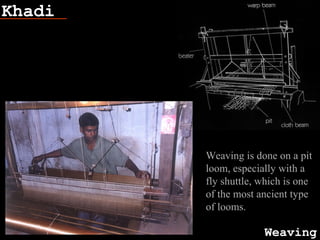

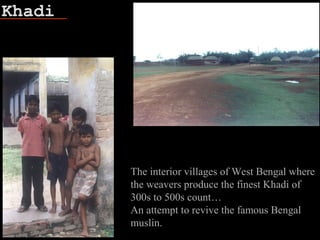

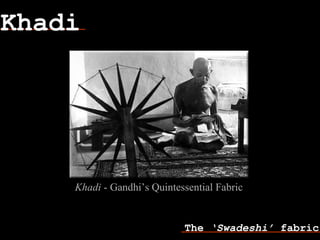

Khadi is a handspun and handwoven fabric that originated over 5,000 years ago in India. Mahatma Gandhi revived the production of khadi in 1921 as part of his nonviolent independence movement. Khadi is created through processes like handpicking cotton, ginning, carding, spinning on a charkha, warping, weaving, and finishing. It is a sustainable fabric that provides employment, especially to women in rural India. Khadi advocates for self-worth and self-sufficiency through human labor.