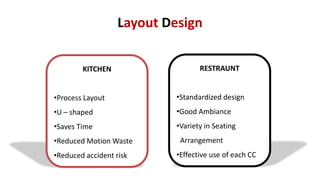

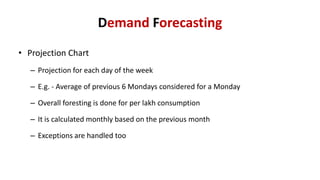

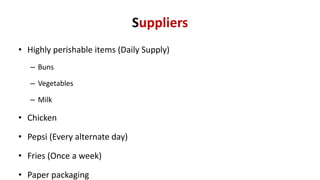

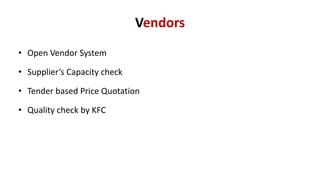

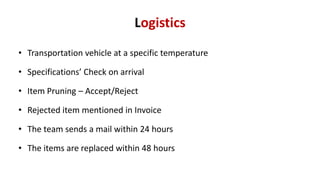

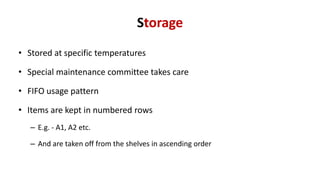

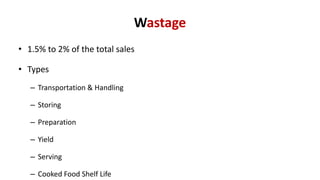

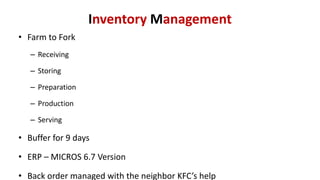

The document outlines key aspects of supply chain management, including hierarchy, layout design, and demand forecasting in a restaurant context. It details supplier management for perishable items, logistics processes, storage practices, and inventory management techniques to minimize waste. Quality control is emphasized with a structured training program and maintenance checks to ensure efficiency and safety.