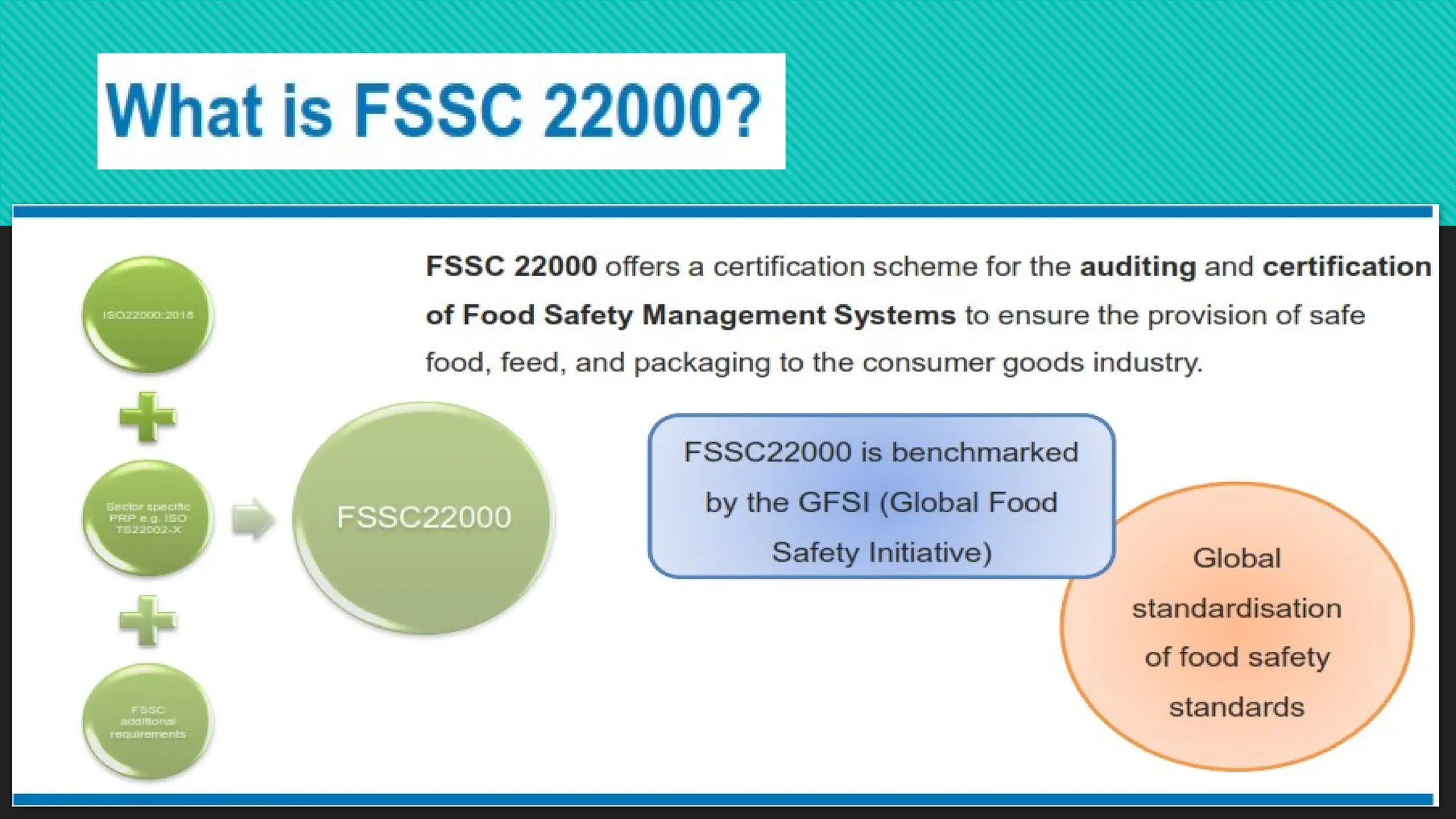

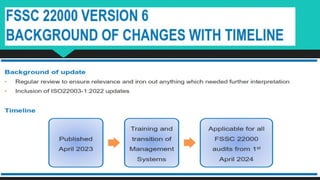

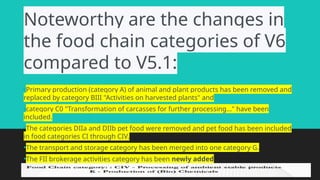

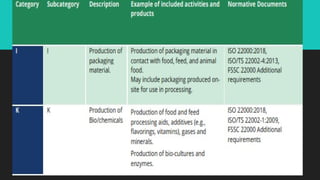

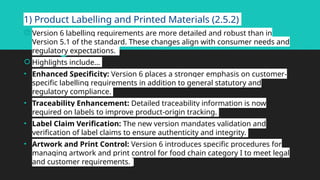

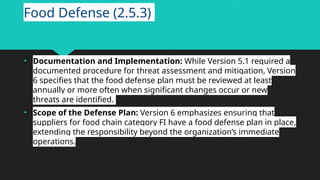

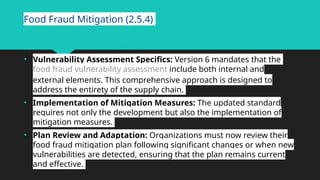

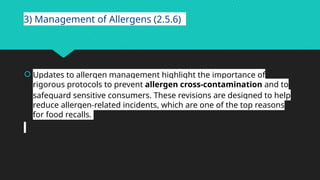

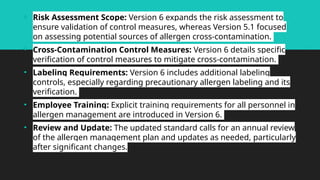

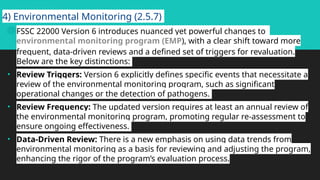

FSSC 22000 version 6 introduces critical updates and mandatory changes effective from April 2023 through March 2025, including the restructuring of food chain categories, enhanced labeling requirements, and revised food defense strategies. The updated standard emphasizes the management of allergens, environmental monitoring, and the establishment of a robust food safety culture while integrating quality control measures and risk assessment for food fraud and contamination prevention. Additional changes address packaging criteria, transport protocols, and communication requirements related to food safety management and certification integrity.