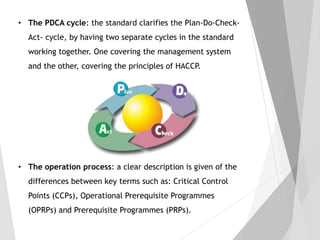

ISO 22000 is an international food safety management standard. The 2018 version of ISO 22000 was updated from the 2005 version to align with the High Level Structure used for other ISO management standards, making it easier for organizations to obtain multiple certifications. Key changes include a strengthened focus on leadership and risk management. The 2018 version also clarifies terms related to Hazard Analysis and Critical Control Points (HACCP) and provides more flexibility in documentation requirements compared to the previous version.