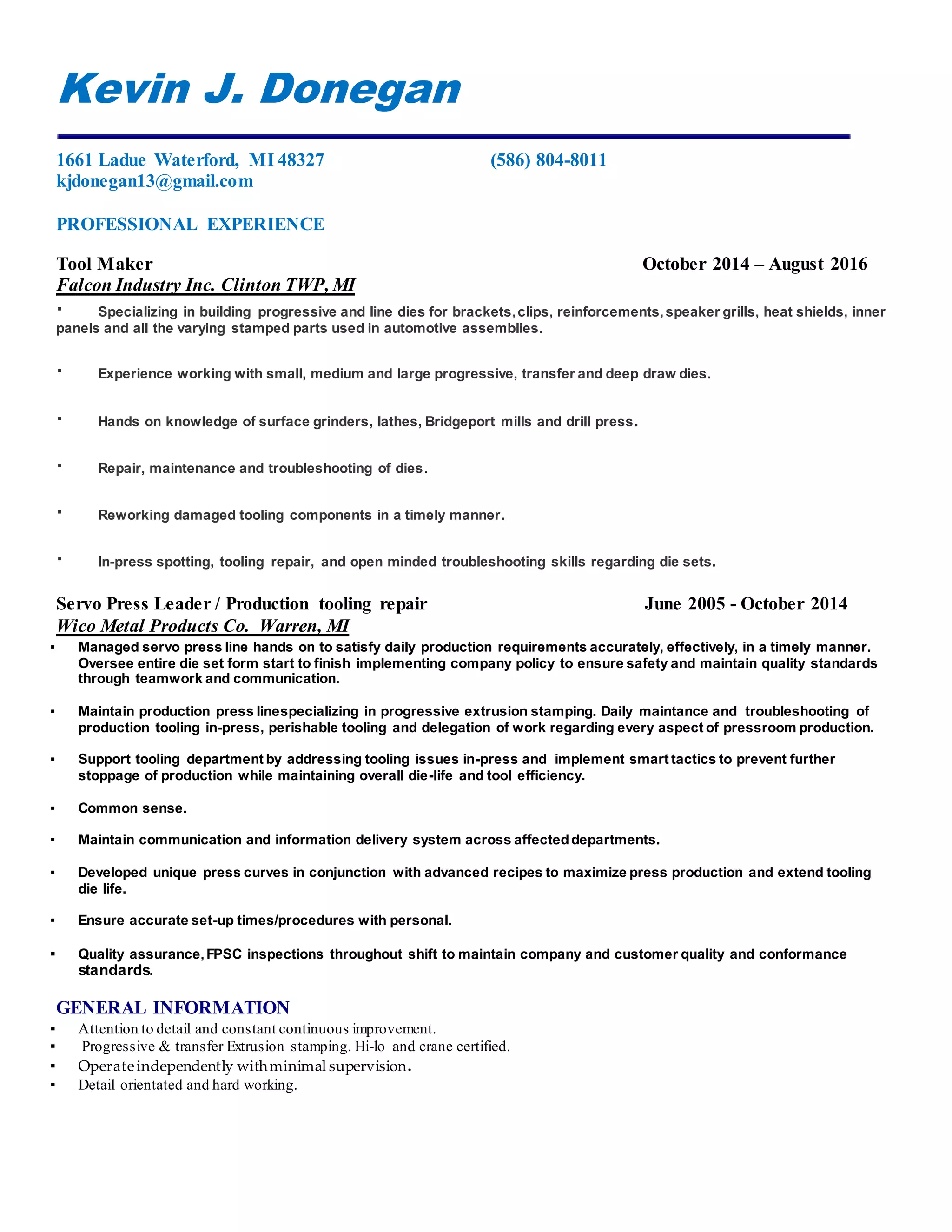

Kevin J. Donegan has over 10 years of experience in tool making and production roles. He has specialized in building progressive and line dies for automotive parts at Falcon Industry from 2014 to 2016. Prior to that, from 2005 to 2014, he managed a servo press line at Wico Metal Products, overseeing die sets from start to finish and maintaining production presses. He has skills in troubleshooting, die repair, quality assurance, and maximizing press efficiency.