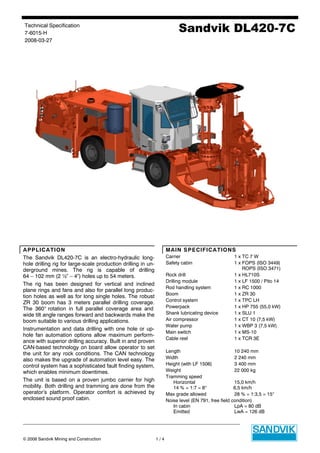

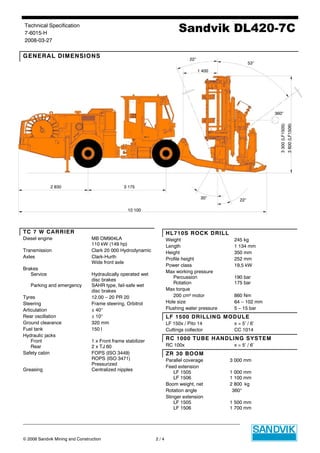

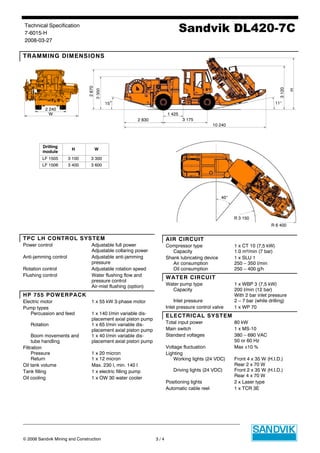

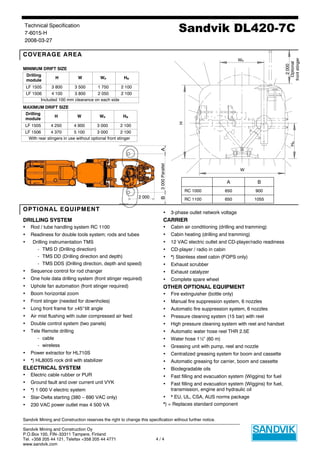

This document provides a technical specification for the Sandvik DL420-7C long-hole drilling rig. The rig is designed for underground mining and can drill holes between 64-102mm up to 54 meters long. It has a robust boom and 360-degree rotation to drill vertically, inclined, parallel and single long holes. The rig is mounted on a proven mining carrier for mobility and has an enclosed cabin for operator comfort.