The document introduces Diamantina Christensen, a newly formed company that was created through the union of two existing companies, Christensen Chile S.A. and Boyles Bros. Diamantina S.A. The new company aims to offer customers a one-stop shop for diamond drilling tools and accessories by combining the manufacturing and logistical capabilities of the two predecessor companies. Both of the company's production plants in Chile and Peru are ISO 9001:2000 certified to ensure quality and consistency.

![A-2

SURFACE-SET DIAMOND BITS

HOW TO ORDER A SURFACE-SET DIAMOND BIT?

Ordering code:

1. Bit size (Chart 1, page A-8)

2. Diamond size (Picture 1)

3. Crown profile (Picture 2)

4. Discharge configuration (Picture 3)

Example:

HQ 25 spc Stepped profile Face discharge for pilot core

lifter case

• Surface-set diamond bit size HQ

• 25 spc diamond size

• Stepped crown profile

• Face discharge for pilot core lifter case

All kind of surface-set diamond bits are available. In addition,

all the orders are warmly accepted according to specific

customer's requirements

Bit Selection

ROCK HARDNESS

VERY SOFT SOFT SOFT / MEDIUM MEDIUM MEDIUM / HARD

ROCK FEATURES

Very abrasive Medium Abrasiveness

Coarse Grain Medium Grain

Very Fractured Fractured Fractured to competent

10-15 spc

15-25 spc

25-40 spc

Picture 1: Available diamond sizes

A. STEPPED PROFILE B. PILOT PROFILE C. SEMI-ROUND PROFILE

Picture 2: Available crown profiles

STANDARD CORE LIFTER CASE PILOT CORE LIFTER CASE

A. REGULAR DISCHARGE B. FACE DISCHARGE C. FACE DISCHARGE

Picture 3: Available discharges configuration

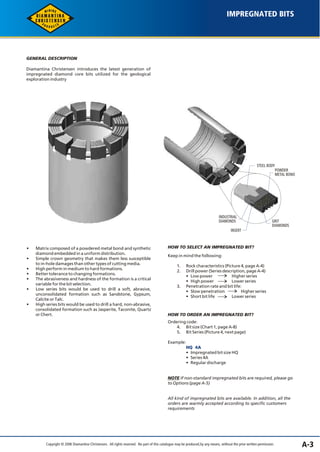

GENERAL DESCRIPTION

Diamantina Christensen introduces the latest generation of

surface-set diamond core bits utilized for the geological

exploration industry

40-60 spc

• Surface-set diamond bits are manufactured by the highest

quality standards to give long service life and maximum

penetration

• Diamonds are set in a pre-determined pattern on the

working surfaces of the bit

• Appropiate for soft to medium formations due to the

greater exposure of the individual diamond crystals.

• Outstanding performance in unconsolidated formations

such as sandstone, gypsum, clay or talc.

HOW TO SELECT A SURFACE-SET DIAMOND BIT?

• For soft and clayey formations is recomended face

discharge

• The higher rock hardness, the smaller diamond embbeded

on the bit. The diamond stone size (Stones per carat [spc] )

available are

- 10/15 spc: Very soft to soft formations

- 15/25 spc: Soft to soft medium formations

- 25/40 spc: Soft medium to medium formations

- 40/60 spc: Medium to medium hard formations

• The profiles available are:

Stepped profile crown (picture 2A): Good penetration and

stability, not recommended in fractured formations.

Pilot profile crown (picture 2B): Provides good stability to

minimize hole deviation.

Semi-round profile crown (picture 2C): Good strength in

broken ground, requires high bit loads.

NOTE If the rock hardness is higher than 6 Mohs is preferable to

use an impregnated bit

Copyright © 2006 Diamantina Christensen. All rights reserved. No part of this catalogue may be produced, by any means, without the prior written permission.](https://image.slidesharecdn.com/catalogodeboylesbross-141001194606-phpapp01/85/Catalogo-de-Boyles-Bross-7-320.jpg)