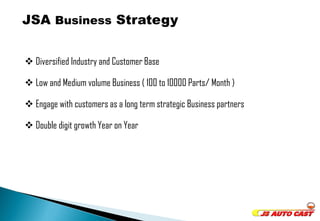

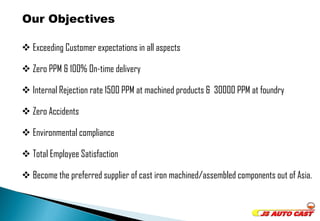

The document outlines the history and growth trajectory of a manufacturing company founded in 2004, emphasizing its production of automotive components such as manifolds and turbine housings. It highlights the company’s expansion, certifications, and strategy for engaging in various industrial sectors, showcasing their commitment to quality and customer satisfaction. Additionally, it details the company’s infrastructure, production capacity, and objectives for future growth.