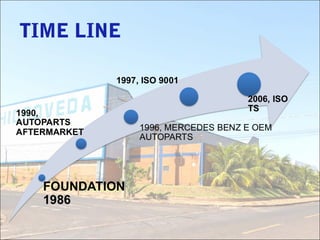

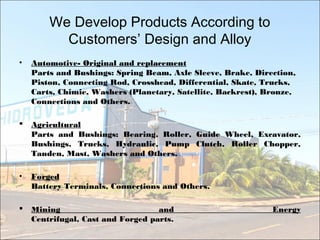

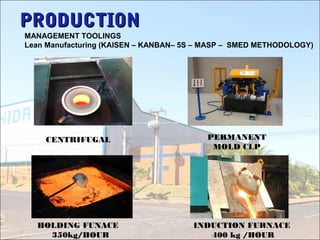

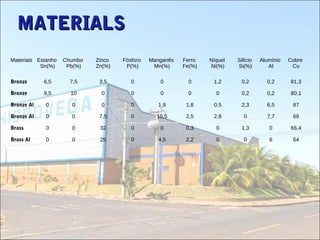

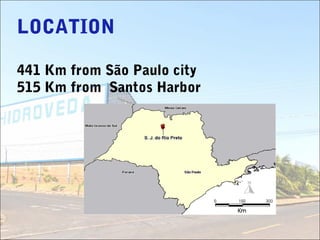

This document provides information about Hidroveda, a Brazilian company that produces castings and forgings of copper alloys. It discusses Hidroveda's mission, timeline, customers in automotive, agriculture, and mining/energy sectors. The company prides itself on quality processes, certifications, and lab equipment. It produces a variety of parts and has the capacity for centrifugal, permanent mold, shell molding, and sand casting. Hidroveda seeks to innovate through university partnerships and improve vision, location, and partnerships with Tecnomarket for access to global markets.