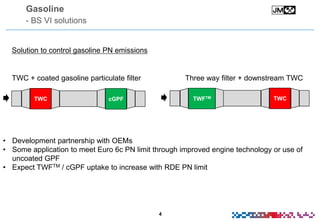

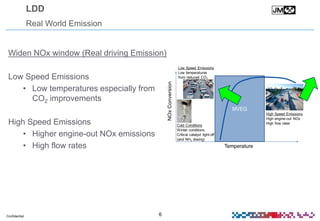

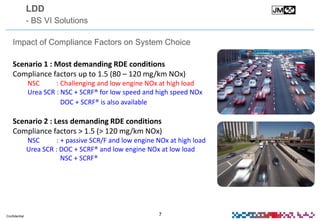

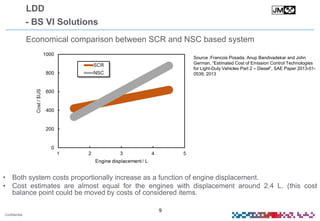

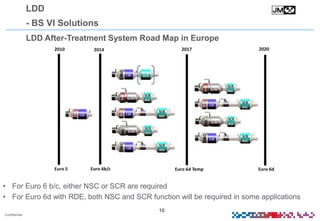

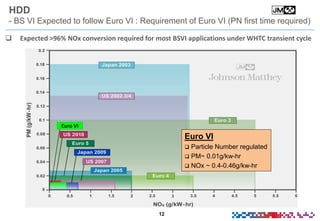

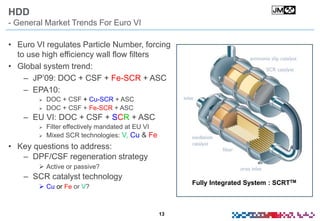

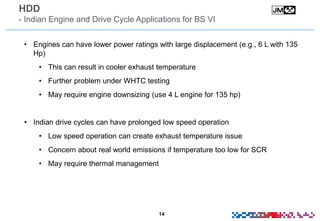

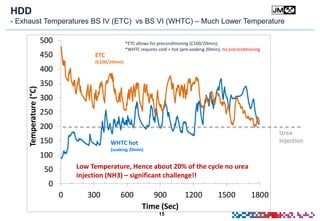

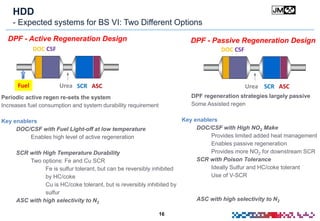

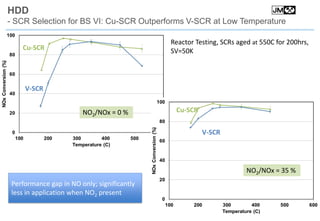

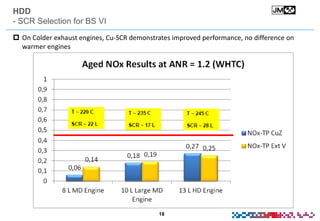

The document discusses emission control solutions for meeting upcoming BS VI emissions standards in India for light-duty gasoline, light-duty diesel, and heavy-duty diesel vehicles. For light-duty gasoline vehicles, it recommends three-way catalyst filters (TWFTM) combined with coated gasoline particulate filters to control particulate emissions. For light-duty diesel vehicles, it suggests that NOx storage catalysts or selective catalytic reduction systems may be needed to meet stringent real-world driving emissions, depending on compliance factors. For heavy-duty diesel vehicles, it analyzes the challenges of low exhaust temperatures and prolonged low-speed operation for Indian drive cycles, and recommends either an active diesel particulate filter system or passive system using copper zeolite SCR