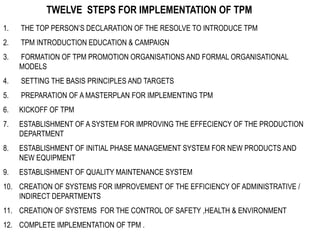

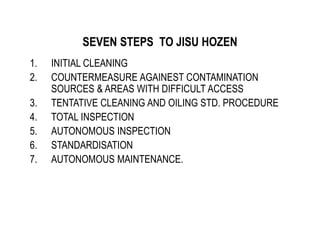

TPM is a Japanese system of maintenance that originated in 1971 based on preventive maintenance concepts introduced from the US. The goal of TPM is zero breakdowns and zero losses through team-based productive maintenance involving all levels of an organization. It differs from preventive maintenance approaches used in the US by emphasizing small group activities and operators taking responsibility for cleaning, oiling and inspecting equipment. Key aspects of TPM implementation include focused improvement, autonomous maintenance, planned maintenance, training and establishing maintenance standards.