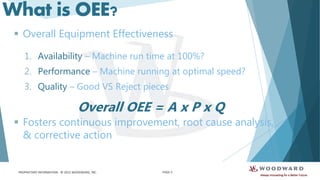

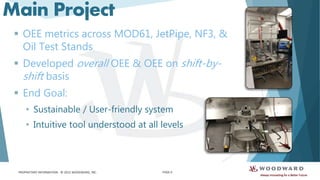

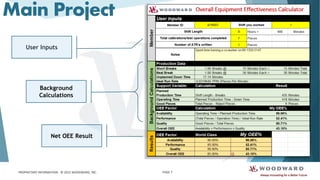

Jeremy Kaszycki presents on his internship project developing an OEE (Overall Equipment Effectiveness) metric and process for Woodward's Servo valve product line test stands. The project involved calculating OEE on a shift-by-shift basis for multiple test stands and developing a user-friendly tool for ongoing OEE measurement. The results were endorsed by Servo leadership and will be implemented across more product lines. In addition to this main project, Jeremy assisted with other continuous improvement initiatives like creating test requirement templates and error-proofing opportunities. He gained valuable experience applying lean manufacturing principles in a real-world production environment.