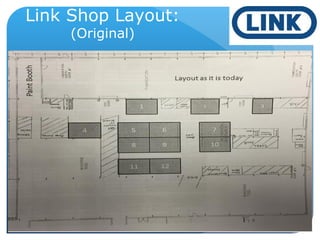

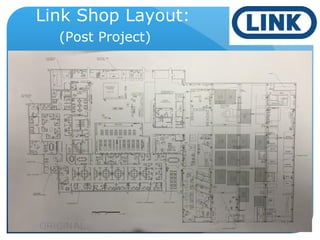

The Full Kit Project at Link Engineering implemented Lean manufacturing to increase production by 30%. The project team reorganized the shop floor into 19 assembly bays where product components come together simultaneously. A new kitting process eliminates downtime by providing all needed parts. Employee input was welcomed, and the changes improved quality, production rates, customer satisfaction, and employee morale while attracting more business. Future opportunities include continuing Kaizen processes and optimizing the logical flow of production.