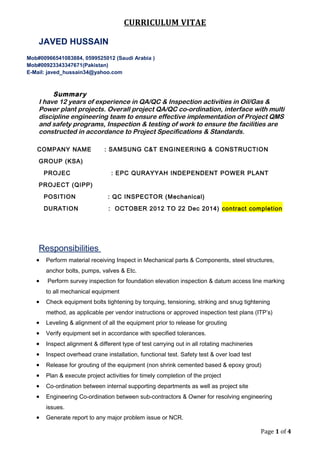

Javed Hussain has over 12 years of experience in quality assurance and quality control roles in oil, gas, and power plant projects. He has worked on projects in Saudi Arabia and the UAE, performing tasks like material inspections, equipment installation verification, and ensuring work is done according to project specifications and standards. His resume provides details on his responsibilities and experience on several projects for companies like Samsung C&T Engineering and Descon Engineering.