Korlepara Venkateswara Rao has over 28 years of experience in quality control, fabrication, and erection. He holds a B.Tech in Mechanical Engineering and various welding and NDT certifications. Currently he works as a QAC Representative for Qatar Petroleum, inspecting welding and ensuring work complies with project qualifications. Previously he has held senior quality control roles for companies in Qatar, the UAE, Georgia, Saudi Arabia, and India.

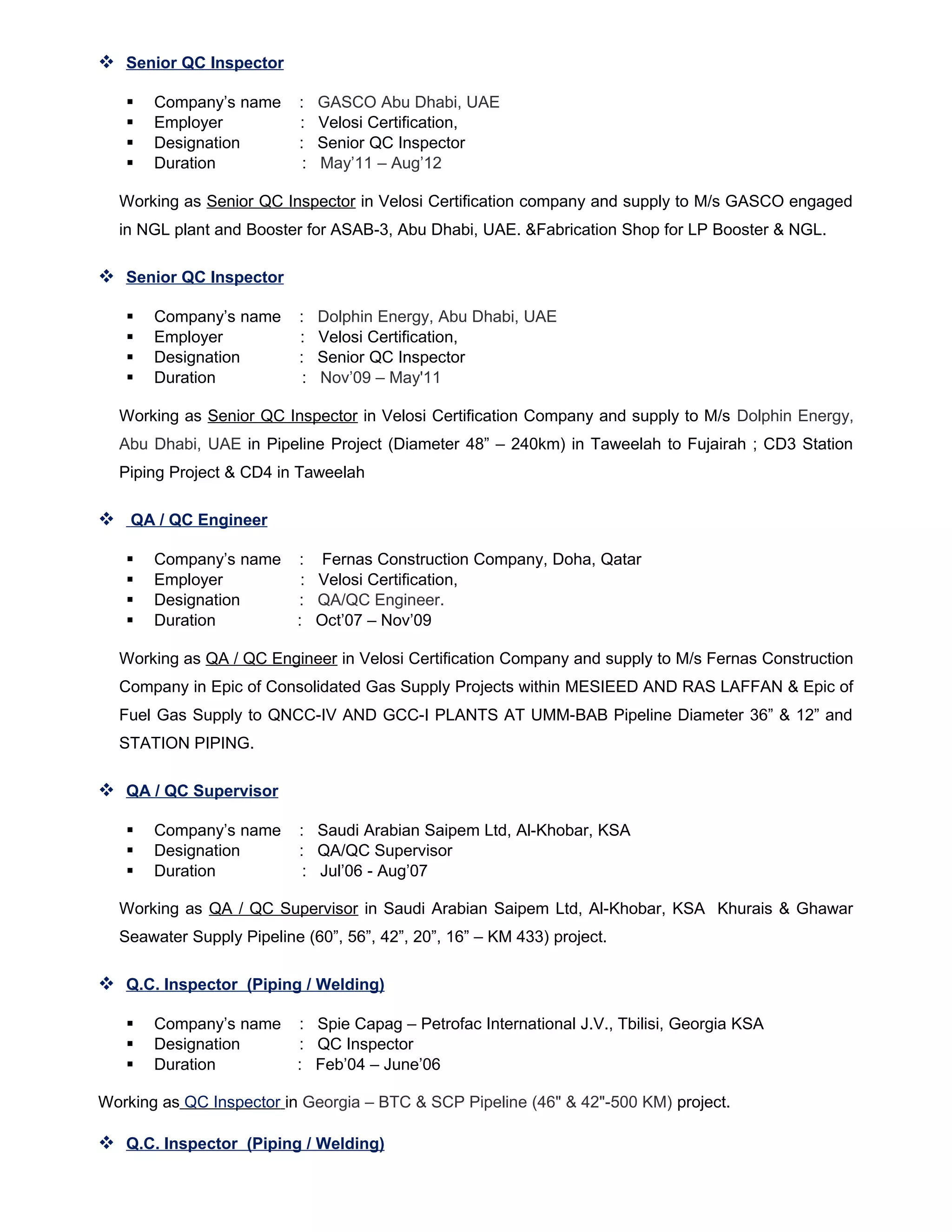

![• Preparation of QA/QC Dossier.

Equipments

Pre Turnaround

• Preparing an Inspection report for Existing Pipeline & Equipment Shell using UT thickness Survey..

• Conducting a detailed Study of Inspection report & Scope of work of each equipment.

• Verification of Gasket, Flanges, Plates (Using Positive Material Identification method) etc.

• Inspection as per ITP & Wall Chart.

Turnaround

• Inspection of Equipments [Inspection for erosion, corrosion & mechanical repairs which occurred

during service. After Opening equipment, conduct a pre-clean inspection & record the findings for

next turnaround].

• Weld inspection of Strip Lining & Weld Build up of Equipment Shell.

• Hydro test of pipes & Equipment.

• Final Punch Listing of Equipment/pipes before handover to Client

• Preparation of QA/QC Dossier.

Previous Experience:

Senior QC Inspector

Company’s name : Dolphin Energy (DEL),Ras laffan,

Employer : Velosi Certification, Doha Qatar,

Designation : Senior QC Inspector

Duration : Sept’13 – April’15

Working as Senior QC Inspector in Velosi Certification company and supply to M/s Dolphin energy

engaged in ‘Export Gas Compression Facilities Upgrade Project & Third Party Gas Interconnecting

Facilities Project, in Raslaffan.

Senior QC Inspector

Company’s name : GASCO Abu Dhabi, UAE

Employer : Velosi Certification,

Designation : Senior QC Inspector

Duration : Feb’13 – Sept’13

Working as Senior QC Inspector in Velosi Certification company and supply to M/s GASCO engaged

in in ‘Diameter 52” – 284 Km, 42’’ – 11 Km) in Habshan – Maqta – Taweelah.](https://image.slidesharecdn.com/c27b8a5c-b740-4d68-8b53-7c5376f0d9f2-150808171658-lva1-app6892/75/Updated-CV-KVRao-Revised-3-2048.jpg)