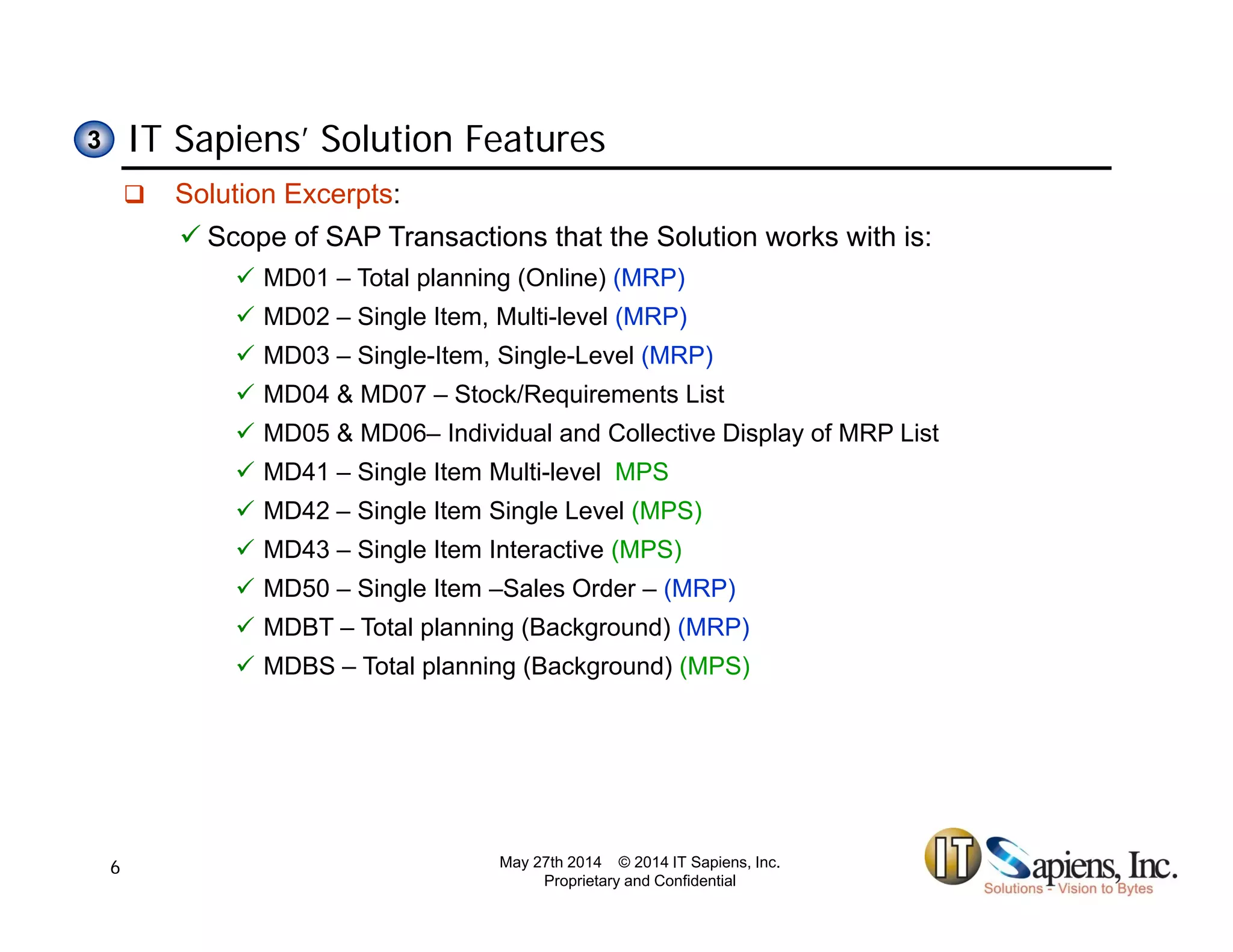

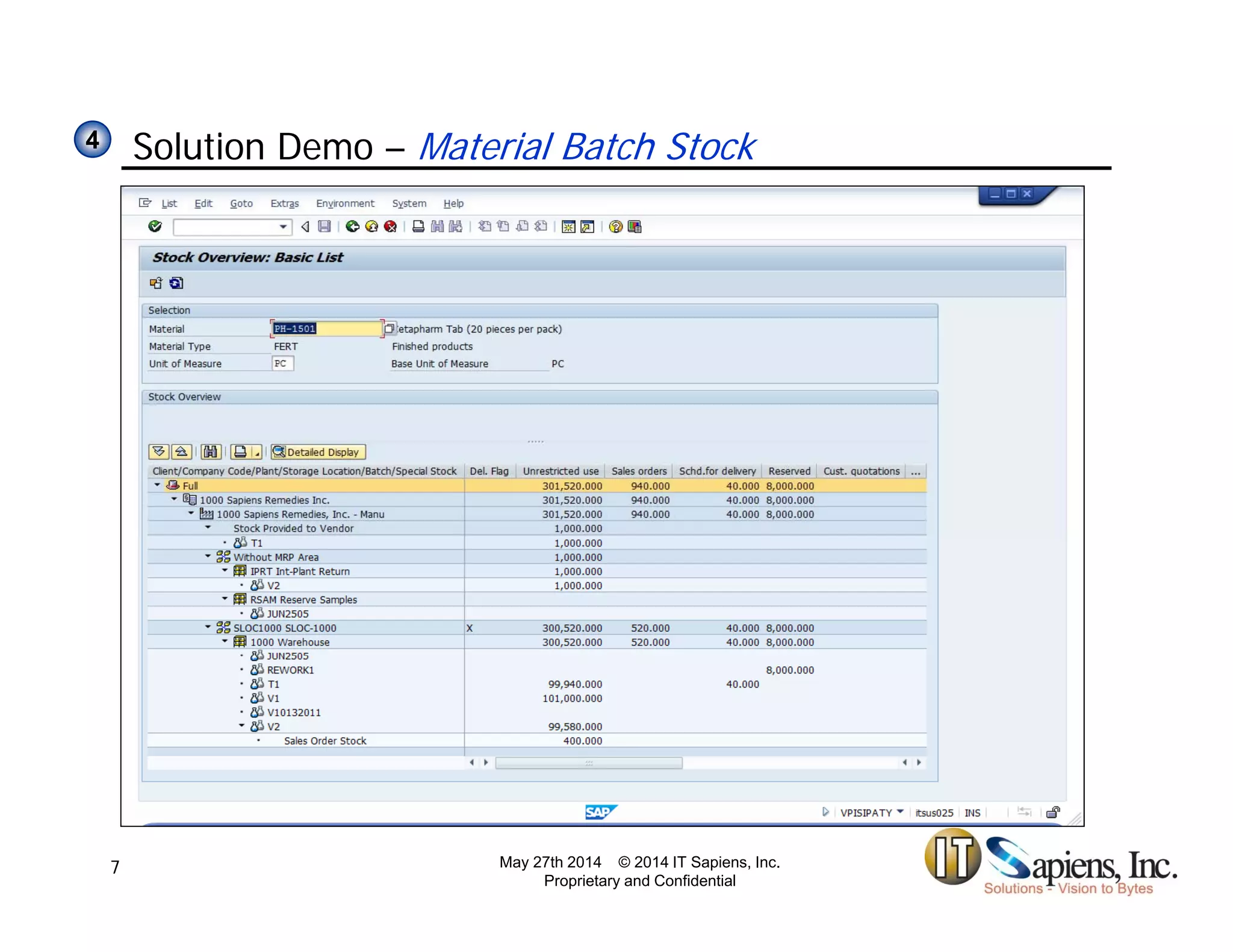

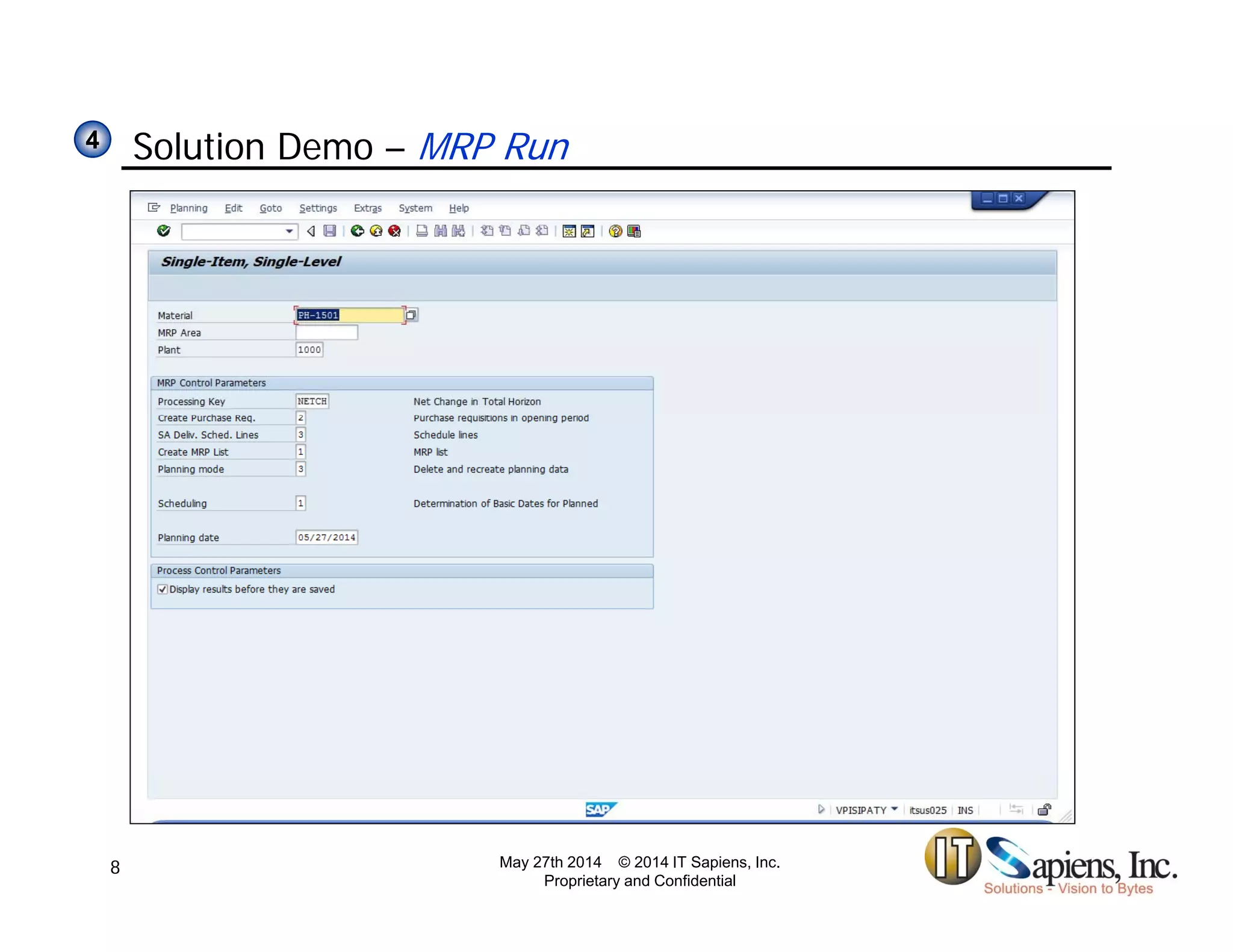

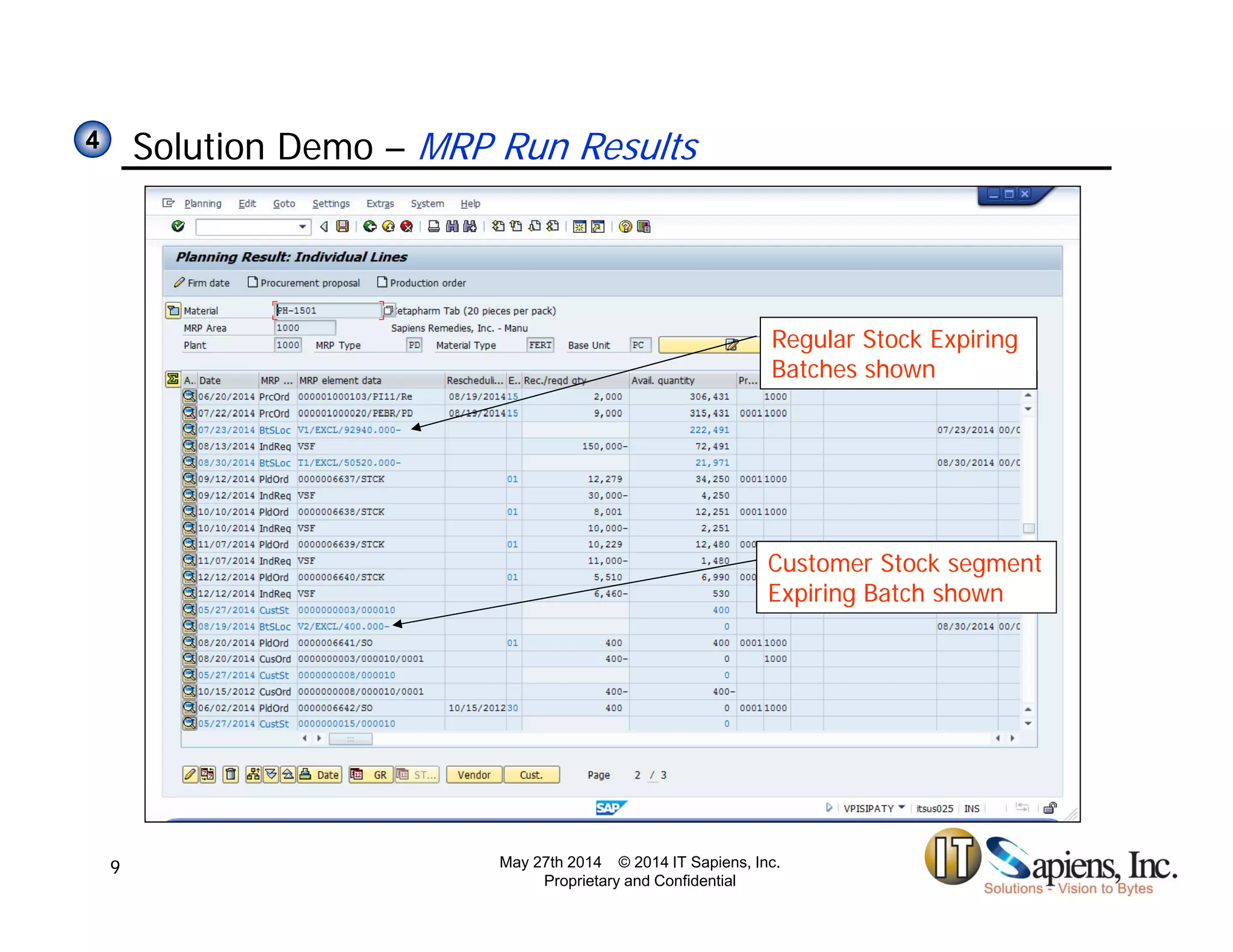

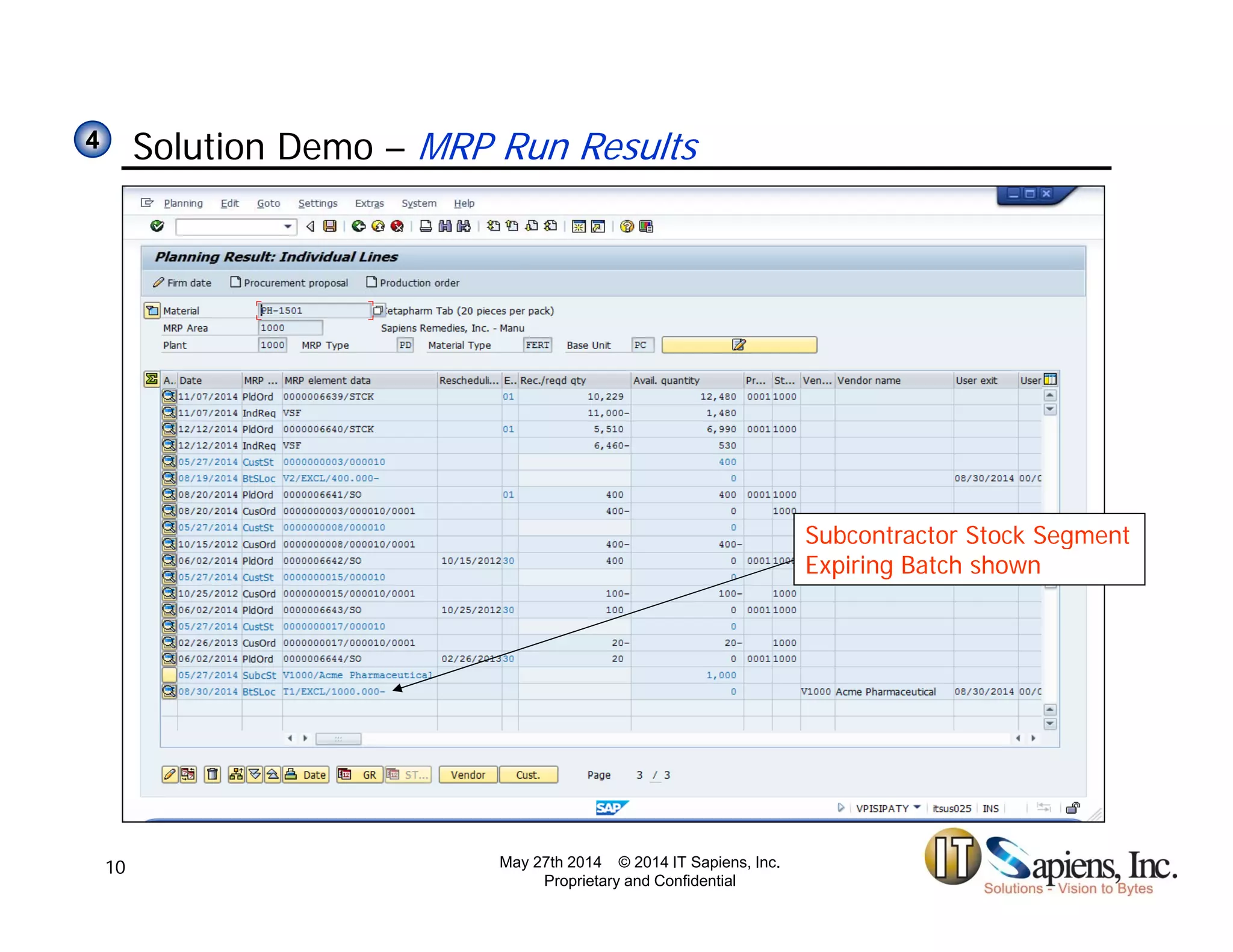

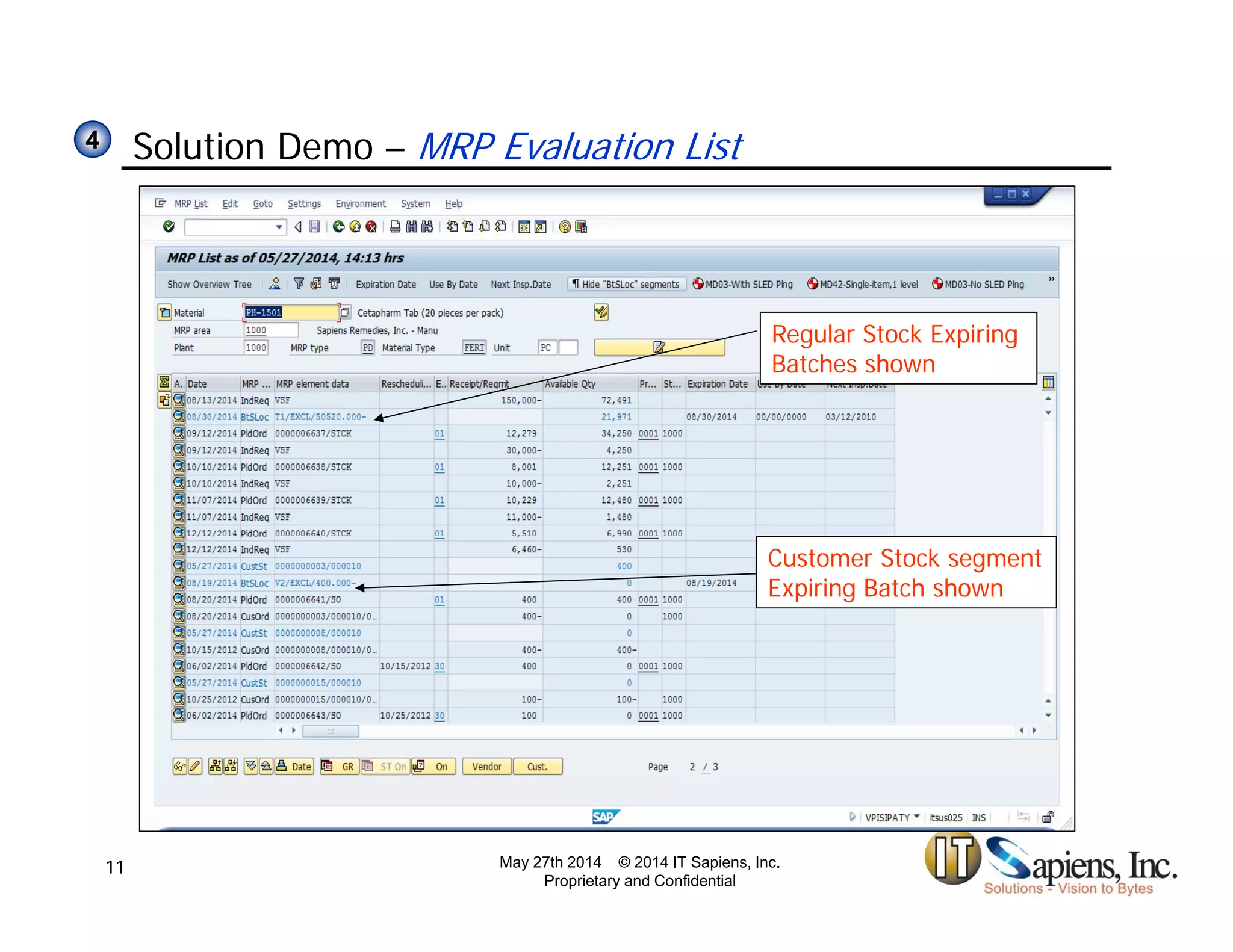

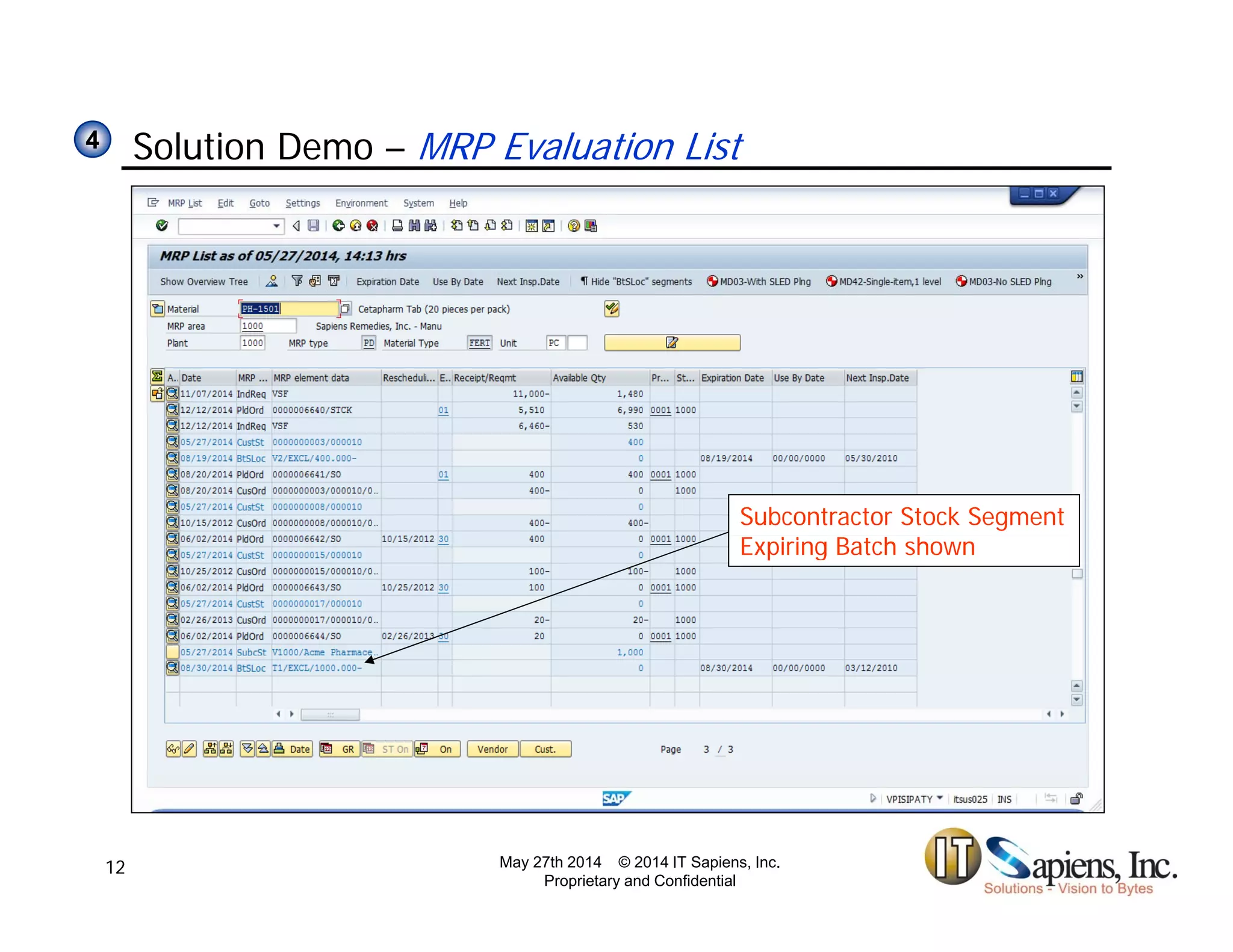

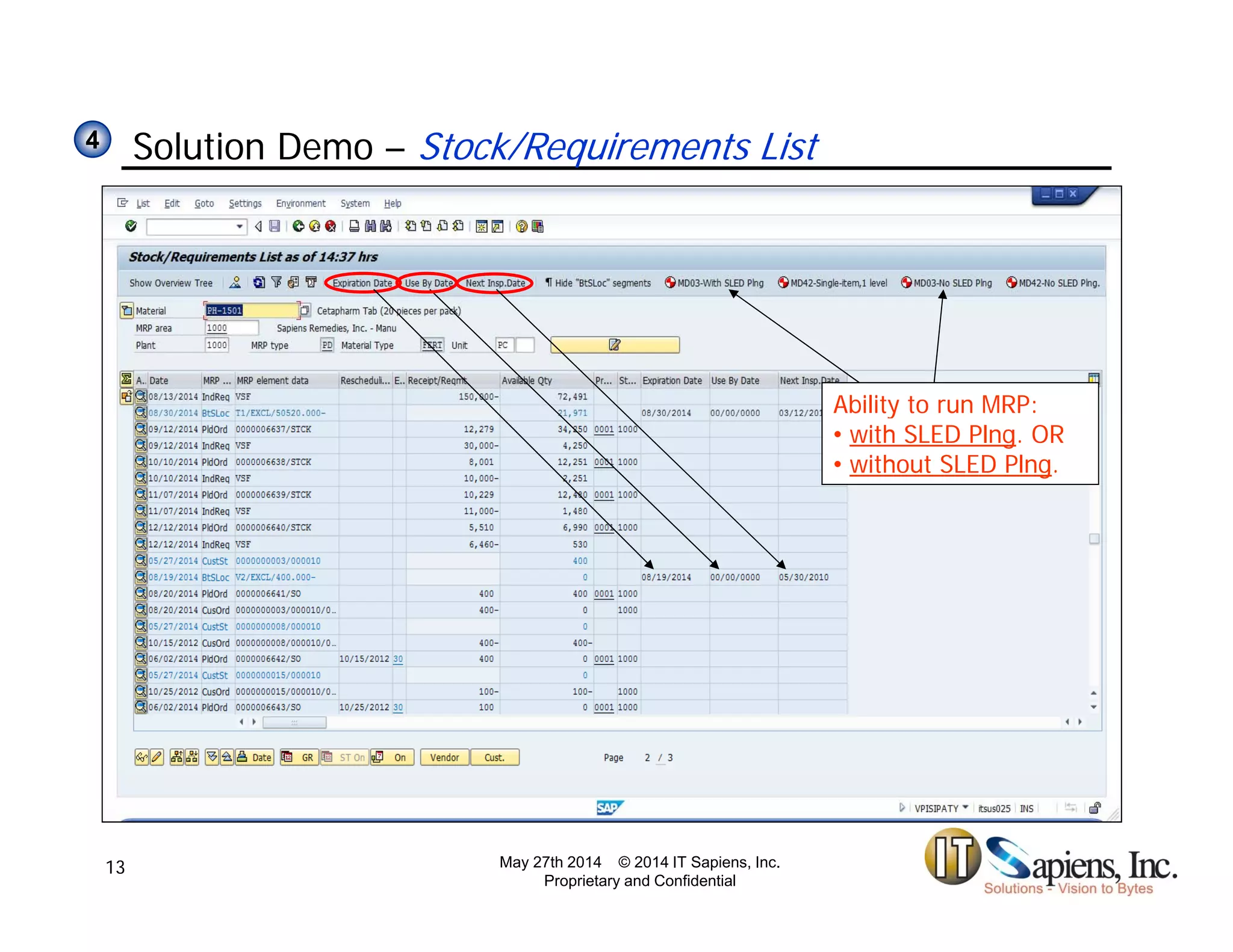

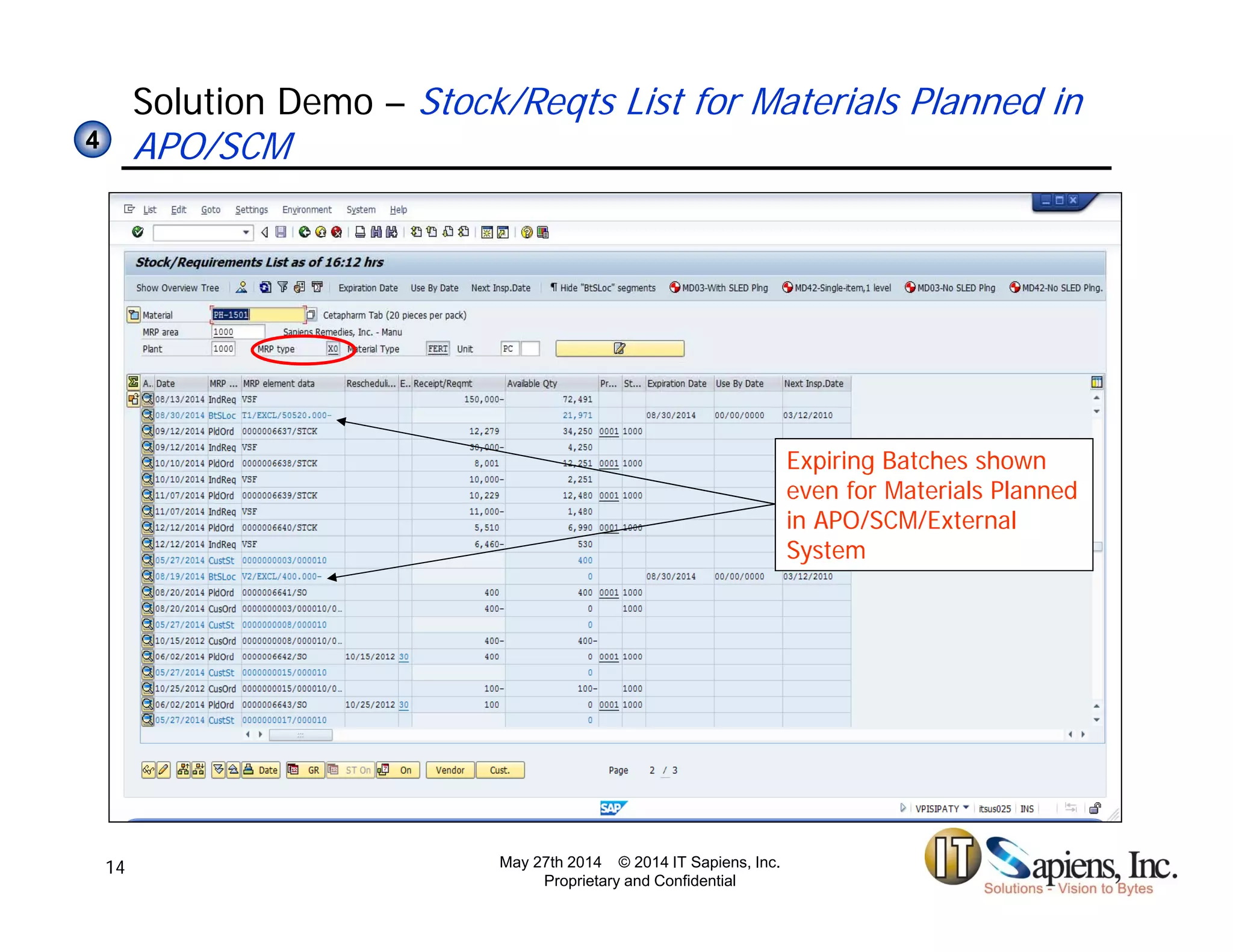

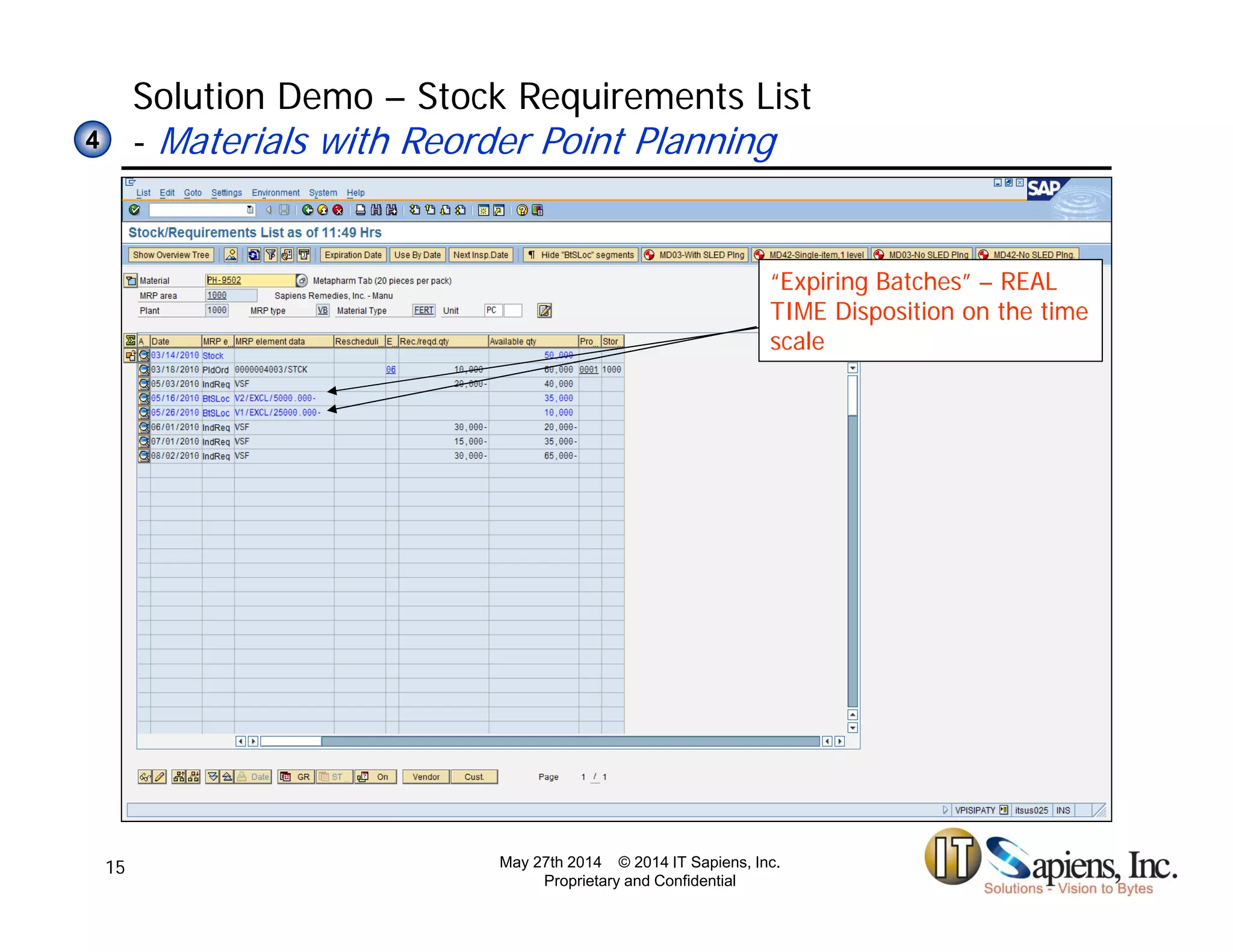

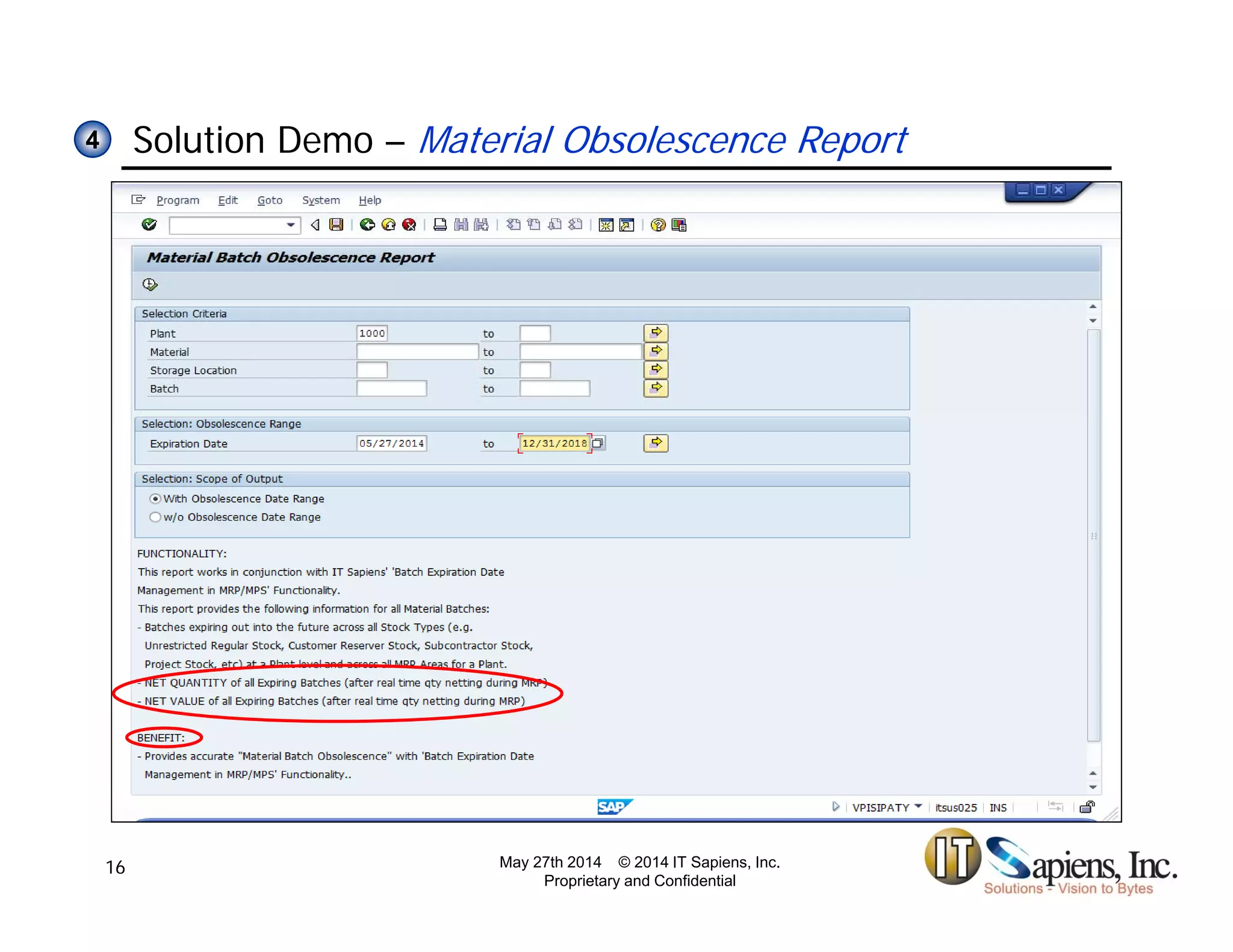

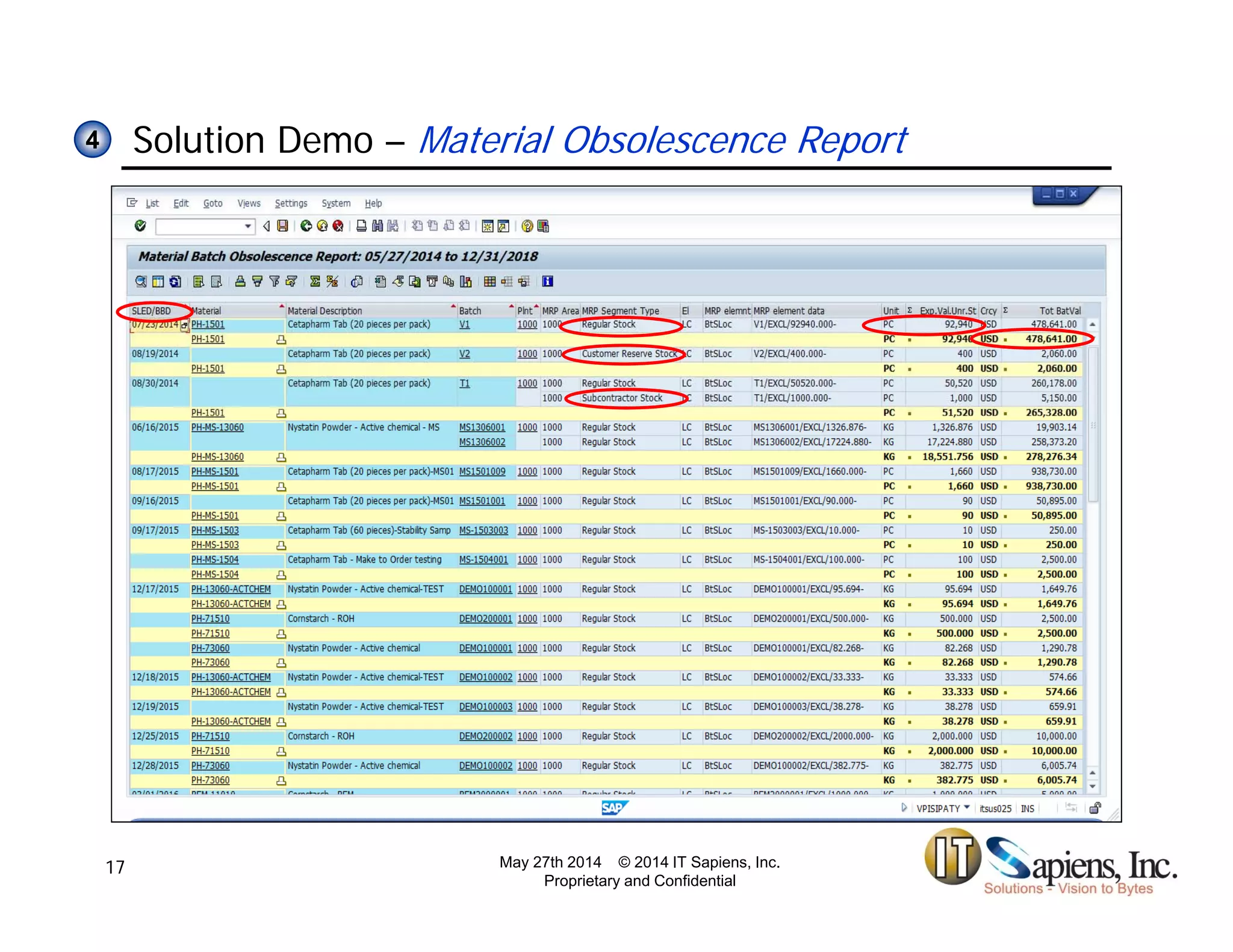

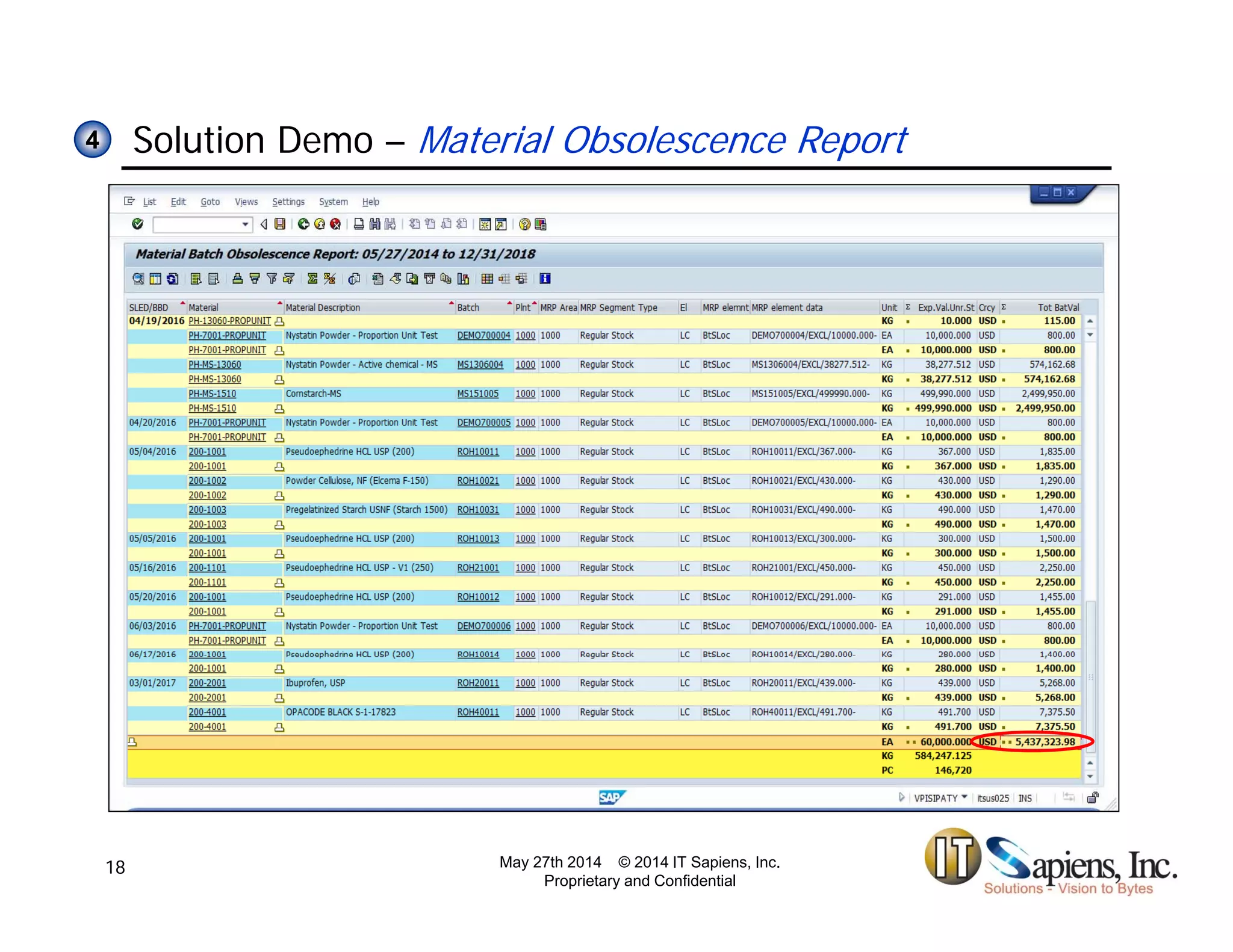

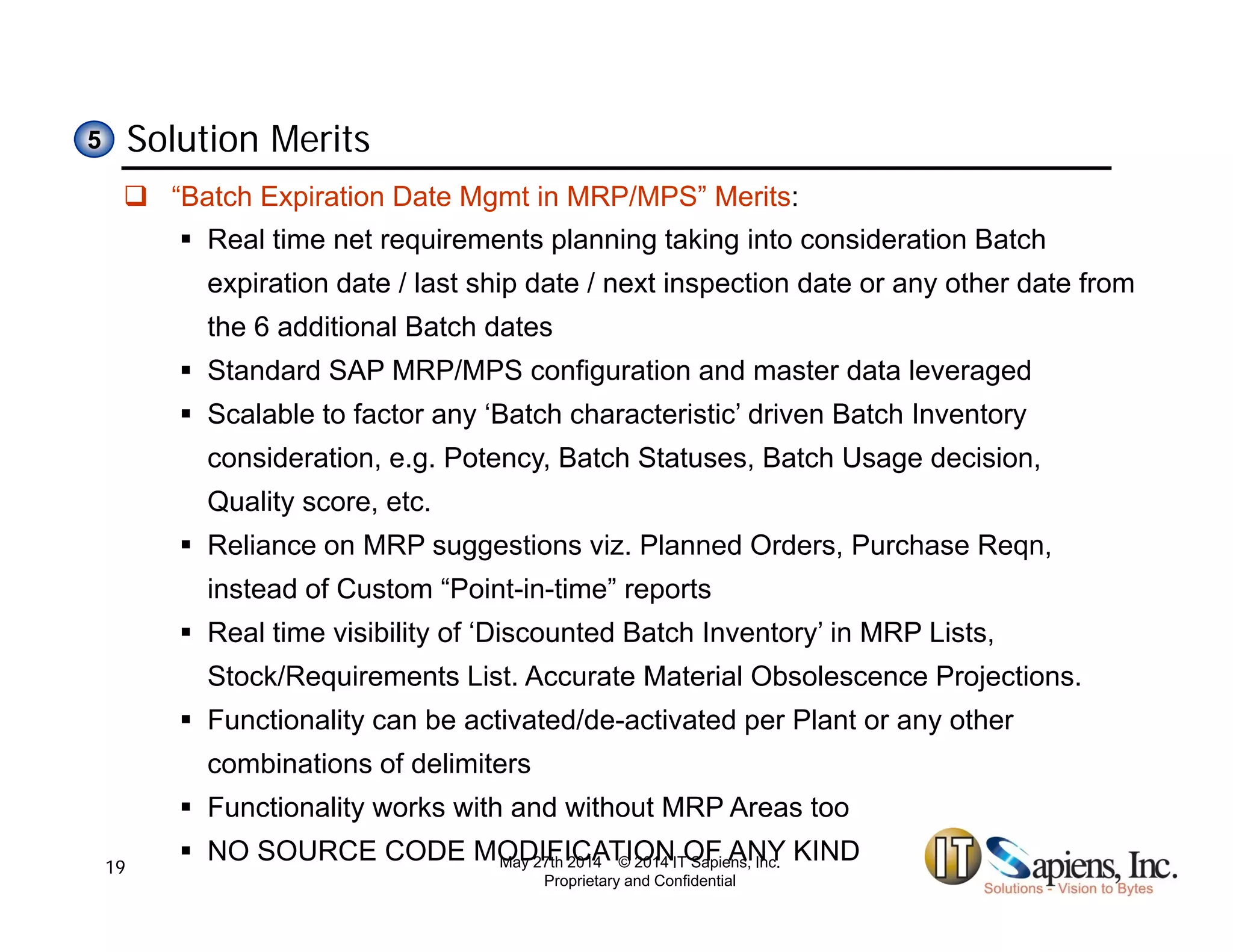

This document discusses a solution for managing batch expiration dates in SAP MRP/MPS. Standard SAP functionality does not consider expiration dates, treating all inventory as available. The presented solution allows MRP to factor expiration dates, accurately reducing available quantities. It displays expiring batches in MRP lists and reports. The solution provides increased inventory accuracy and improved material obsolescence projections without code modifications.